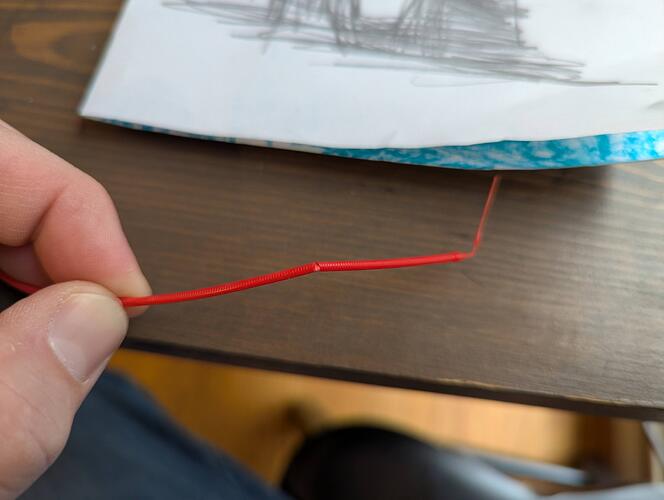

I had this same issue. At first it was intermittent; the filament would cut most of the time but occasionally would not cut all the way and then would jam. A couple of weeks ago, the issue got worse to where it would not cut at all. After many attempts and disassembling the extruder multiple times, I noticed it appeared that the cutting blade was not pushing far enough into the extruder. I don’t know what may have caused this, but I’ve recalibrated several times after patches etc. and this did not fix the issue, so I turned to a hardware fix.

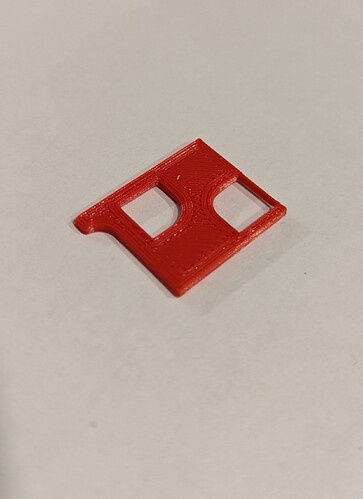

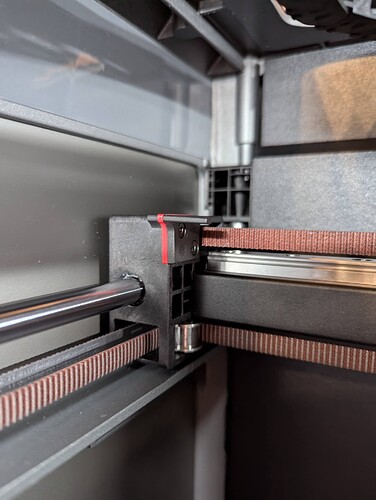

I removed the filament cutter rod and modeled a spacer to fit behind it. The spacer allows the cutter rod to extend slightly further into the extruder and push the cutting blade far enough that it effectively cuts the filament every time.

Given that the tolerances are fairly tight, the spacer is sized at 1mm with the intent you can scale up/down or print multiples and sandwich them together until you find the appropriate spacing to allow the cutting blade to reach far enough but without pushing too far and causing damage to your extruder. I started small, with just 1 spacer and increased until I found the right thickness to cutoff the filament consistently (I ended up with ~2.5mm of spacer on my K2 Plus).

I’ve run my K2 for several hours on a color changing print and then disassembled the extruder to look for any signs of wear on the inside (any potential indication the cutter was pushing too far into the extruder) but I did not see any signs of this.

I uploaded my model here:

Creality Cloud -K2 Plus Cutter Rod Spacer From KGS_Engineering

Here’s a couple of pics: