One of my favourites, but not mine - either Oscar Wilde or Mark Twain in all likelihood. I did check once, but I’ve forgotten - so feel free to use, though I sometimes add the caveat that “A big pile of incompetence is a good place to hide a little malice” (the caveat IS mine, but I’m happy for you to use it!

On to drying…

Yes filament absorbs moisture.

But I’m pretty sure* it’s not a one-way system , even in the absence of heat. It will be an equilibrium. The filament won’t simply keep absorbing until it dissolves.

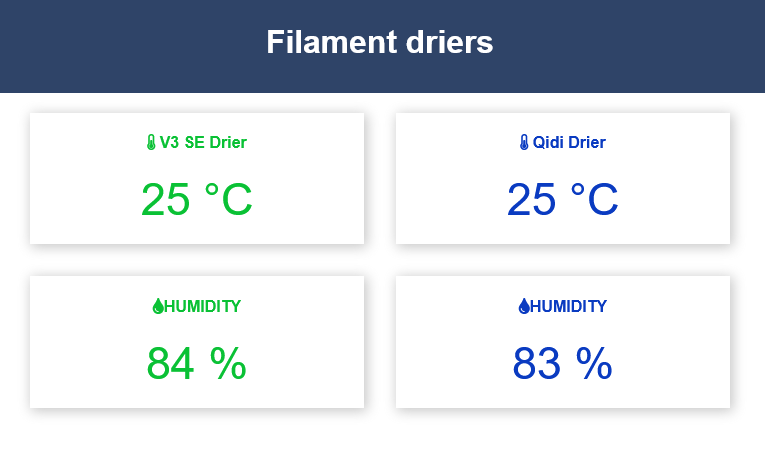

Heating raises the equilibrium in favour of drier filament, but I agree with you that if you take 100 grams of moisture out of the filament, but leave it in the local volume of air, there’s nothing to stop it going BACK in the filament. Also, removing the air means replacing it with new air, which probably has a non-zero moisture content. An acceptable alternative is thus to recycle the air, through a moisture “trap” like silica gel…hence my hygrometer activated drier idea.

My theory is that even at room temperature, it is possible that moisture could leave the filament if the air around it was dry enough. The only way to test this would be gravimetrically - and also keep it within the constraints of reality - so none of this immersing a spool in water for a month beforehand!

I’d suggest (if I had the kit).

Store a spool at 80% rH and 20°C for a month.

Take a sample of the filament and weigh it. Put the sample in an oven at 105°C (it doesn’t mater if it melts)and keep weighing it until the weight stops dropping.

The loss in weight will be water, plus a few (very few, if stored at 80% rH) VOCs.

THEN

Pack the spool in a crate filled with desiccant silica gel with the “I am wet” colour indicator (or use a device similar to the one I designed. Replace any gel that has changed colour, until none changes colour for 24 hours.

Repeat the gravimetric test and you have a measure of how much water the desiccant gel “pulled” out of the filament just by drying the air around it - no heat.

Moisture in filament is currently the 3D printing “bogeyman”; everyone says it’s bad, but no one really understands it in detail. However it’s achieved, it would be nice if we could build a database of the water contents of different filaments - the maximum they can absorb (so yeah that is the “Month in the bath” test) the minimum they can be dried to (is 0% moisture even achievable?) and a recommended “ok to use” range (because even if 0% IS achievable, we should not assume that it is desirable; it’s perfectly possible a small amount of moisture might help with certain properties, in certain filaments).

- “It’s not what you don’t know that gets you into trouble. It’s what you know for sure, but just ain’t’ so” - and that IS Mark Twain.