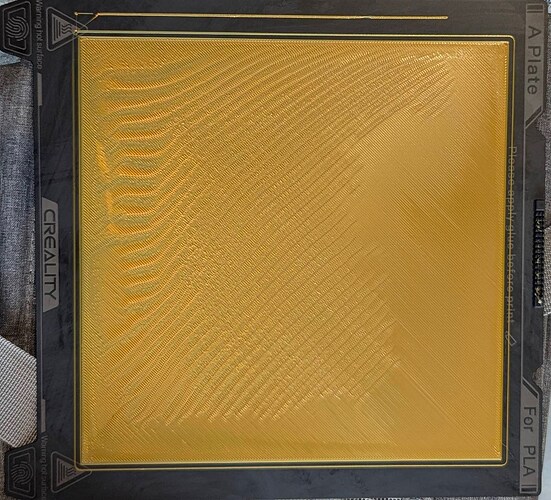

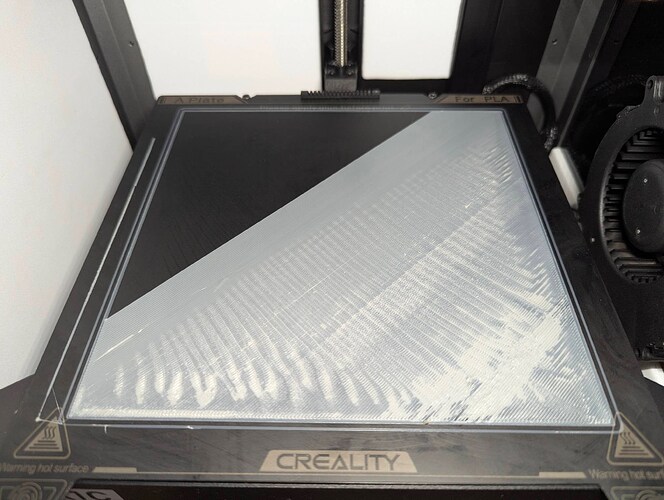

I just bought the K1C. in the first couple of weeks, it printed great! then the prints starting looking bad, with uneven surfaces. i updated the firmware today and ran the self test again, then printed this test print in the photos (a square of 1 layer thick). This layer was 0.2mm, printed with PLA silk, 100% extrusion, at 45 mm/s, 220C nozzle and 60C bed temps. I changed the filament to PLA +, ran the self test again, and still printed the square just as before.

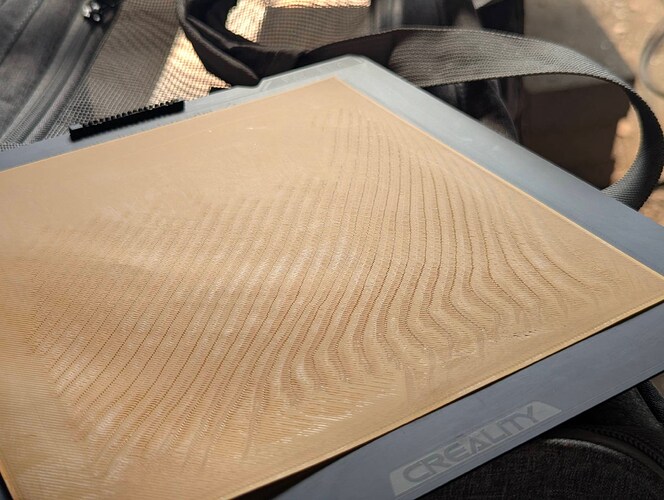

You can see the differing Z heights and wavy XY lines, but it makes a pattern only in part of the bed…which tells me it’s not an extrusion problem, nor a vibration problem, nor speed. the last photo is of the bottom of the print to show the holes it created, which means the nozzle is lifting as well.

the skirt line also shows there is a leveling problem - even though this was printed right after the self test; in the back right corner, the line was slimmer on the XY and thicker on the Z axis, and the line at the front left corner was wider on XY but so thin on Z axis, it’s translucent.

The motor does not feel jerky when it was printing and the belts feel properly tensioned and not loose. It’s just not printing a smooth straight flat line. What could cause this and how do I fix it?

Wobbly lines looks like the z offset is too close to the bed, adjust it up by 0.05/0.1mm or you are overextruding try adjusting the flowrate to 85/90% to see if it improves.

That bed looks pristine. Super flat and no scrape marks. Nice. I am sorry for your woes.

Seth

P.S. Hopefully, you guys/gals can get it fixed up and done! Also, every time there is an update, reset your arguments in the GUI or via another way. I say that idea because the last update that I updated blindly got me back to square one with arguments. There is also a new update for firmware for the K1C I just grabbed…

The bed is almost brand new, i just got it a couple of weeks ago, and then we started using the G10 plate for PETG printing, so the smooth one that came w/ the printer was hardly used. I switched back to PLA, so switched the plate back, and started getting all these problems.

How do you set the arguments, and which ones need to be set?

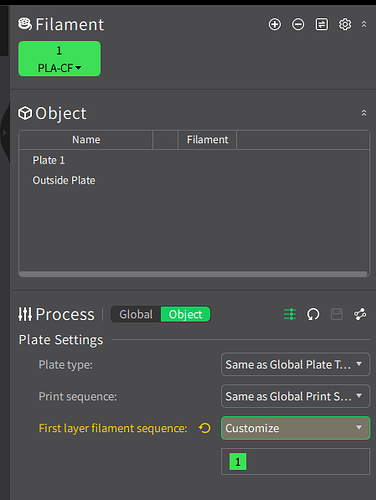

Okay…you have global and object. Some global parameters/arguments can be set in the GUI/Slicer/Host Software.

So, please view this photo and then I will explain more…

That is object arguments. Call them whatever you like really. They are values/arguments/options/whatever…

So, First Layer Filament Sequence I leave on Auto usually but you can change it to suit your needs of what type of Filament you are using.

To the left of object is Global where most arguments are listed. You can also change your filament type, speed, and so on and they all have different key:value pairs. So, traversing the bed may be too fast at times on specific prints with various filaments. Try to slow your mm/s on accel and decel.

Also. Another one that gets me is that the hotend cools rapidly to any wind in the chamber. Set your fans to medium to three-fourths of their full capacity. PWM is controlling those fans. You can alter them…

And another thing here…

- The top, right of the photo will allow you to change in the GUI from PLA to ASA and back to another type if need be currently. So, if you were using PETG, try to use a setting similar to PETG for the GUI filament type.

- When clicking Global instead of Object, click the three lines that look like three lines on the GUI photo and then it will list all of your arguments listed.

- So, you will have more “control” of your print.

For instance, if I was using PLA-CF, which I am, I would pick that specific nozzle I am using and that type of filament to list the various parameters/values/arguments and then change to suit my needs depending on my print or speed control.

Just remember, that fan will cool your K1C quickly and to the point where it will shutdown the print midstream.

Seth

Also,

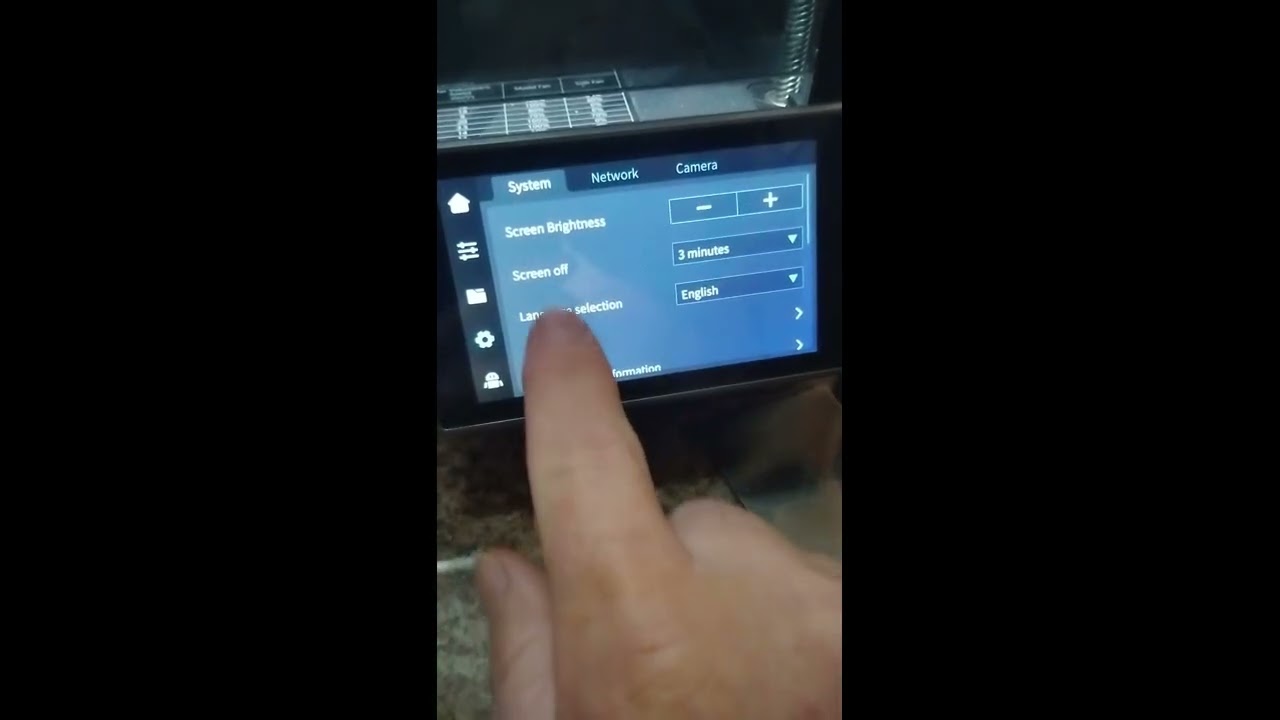

@Hue_Le , I noticed in the control board interface (LCD), there is a two-option setting that deals primarily with leveling and setting the build plate ratios for input shaping.

So, here is a short video on it and this may help. Remember to change physically the filament and filament in the GUI too. So, if you are using ASA physically, use the ASA option in the GUI and change from that point forward to suit your needs:

Video:

Enjoy and repeat!

Seth

i tried changing the flow and it made it worse, so i changed it back to 100%. increased the z offset and it got worse, so i decreased it, all the way down to 0.100, and it fixed it ![]()

thank you so much!

I was unaware of the z-offset but yeppers, that plays a role too.

Seth

Yeah, apparently. what could change the z offset out of the blue like that? it was just fine one day, then just went bad the next day.

thanks for the explanations and suggestions up above, i’ll look into them and see what i can change ![]()

Just guessing, but a slipping belt could change lots of things. Are they all snug?