All my 3D prints with K1 Max are coming out faulty, and I couldn’t find a detailed manual for Creality Print online. I have performed all the calibrations under the “Calibration” tab in Creality Print, but my prints are still faulty; the bases of the prints are stringy and stripy. How can I prevent this? Can you help me with all the settings I need to make? I am using PLA filament and have reduced the print speed to nearly 150, but it still doesn’t help. I don’t know what to do.

My first guess would be to make sure the model is flat on the build plate in the slicer. It’s possible that it is raised up a little so the slicer is building a raft underneath.

Which version of Creality Print are you using…?

Send a pic of the first layer.

There are many YT videos online with tutorials for what ever slicer you are using…

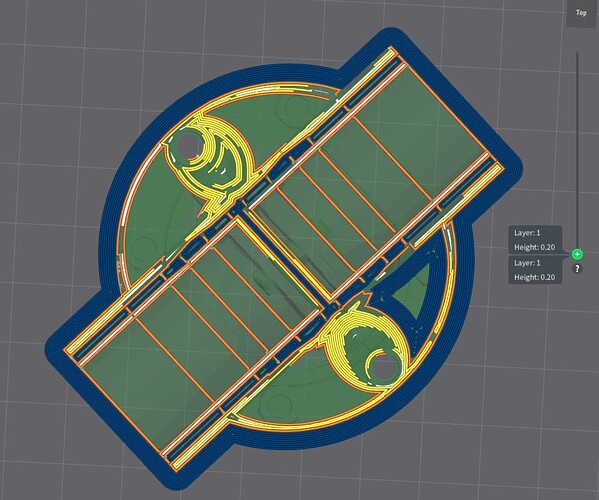

Check all your settings in the slicer and try to set them all back to default. The spacing between the lines shouldn’t be the much.

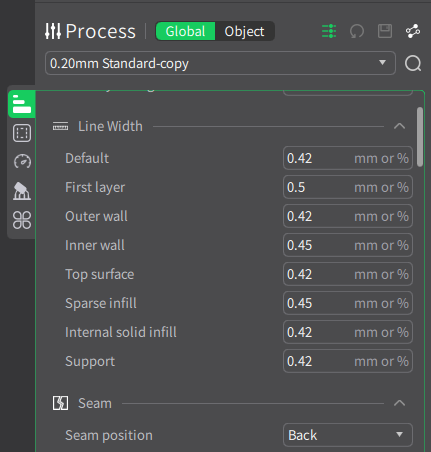

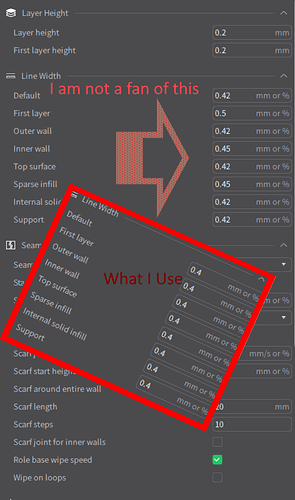

These are the default settings I use on Creality Print 5.xx

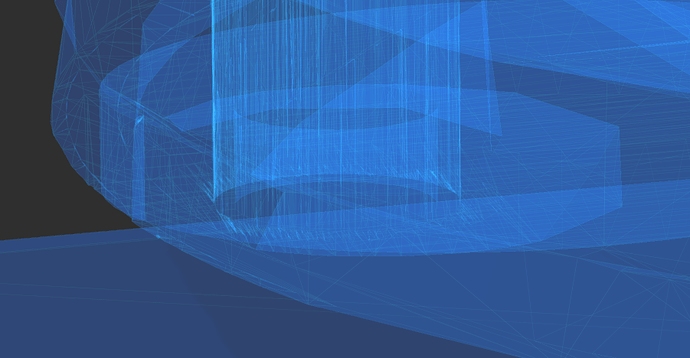

Someone more experienced with Creality Print could jump in with a better diagnosis but this is something to check… ![]()

I will try thank you

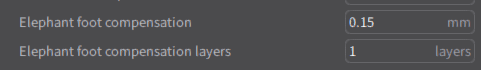

There are a few booby traps. I believe they put these things as defaults (and omit others) to save us from ourselves.

If you do the math here, your print can be out by 0.65mm which is NOT insignificant.

Hope it helps!

Thank you for your help and response. I am trying the adjustments you suggested, and I will share the results with you

Try adjusting the bed leveling and ensure the nozzle is clean. Increase the print bed temperature slightly and check for proper filament tension. Consider using a slower print speed, around 60.

Just like tweaking settings in FM Whatsapp APK can improve performance, fine-tuning your 3D printer’s settings can make a big difference.

What do you mean by “your print can be out by 0.65mm”? Do you mean the print can be smaller than it should be? If so, in which axis? How did you do the maths to arrive at the figure of 0.65mm?

What are your build plate adhesion settings?

Since the release of CP9904, prints have had issues. 9904 is a steaming pile disguised as code.

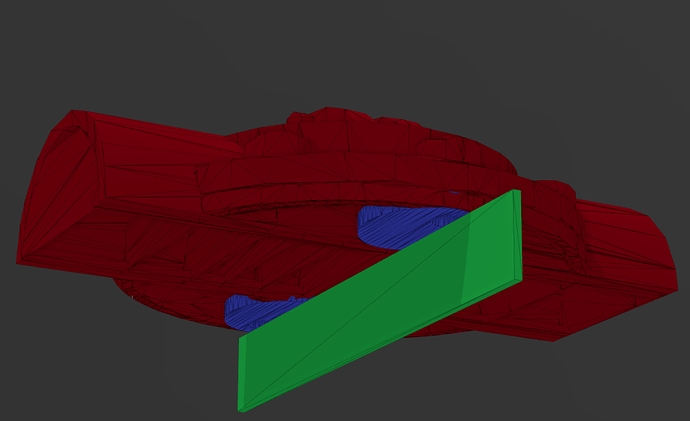

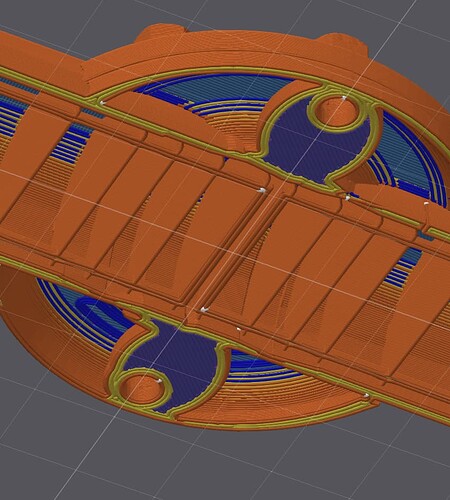

Example I sent (I have many others):

The Model. Green straightedge to show underside of print being perfect for printing. NOTE the Blue feet.

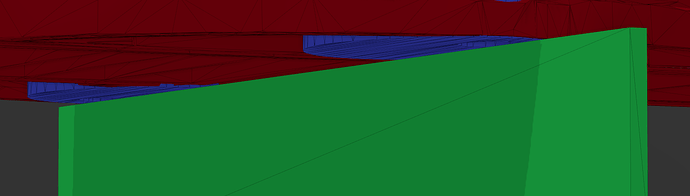

Just a closeup for the nit pickers…move along…nothing to nitpick here…lol

So here is the x-ray. I actually built feet on/over the original feet due to printing issues. Lotsa nice solid plastic there (16 walls, monotonic, 0 angle, again- trying to solve print issues)

Here’s the fun part. I only had Cprint installed, so I snagged a couple other slicers.

First up: Galaxy Slicer (just because it got real bad reviews)

Look at that 1st layer, pretty nice and smooth.

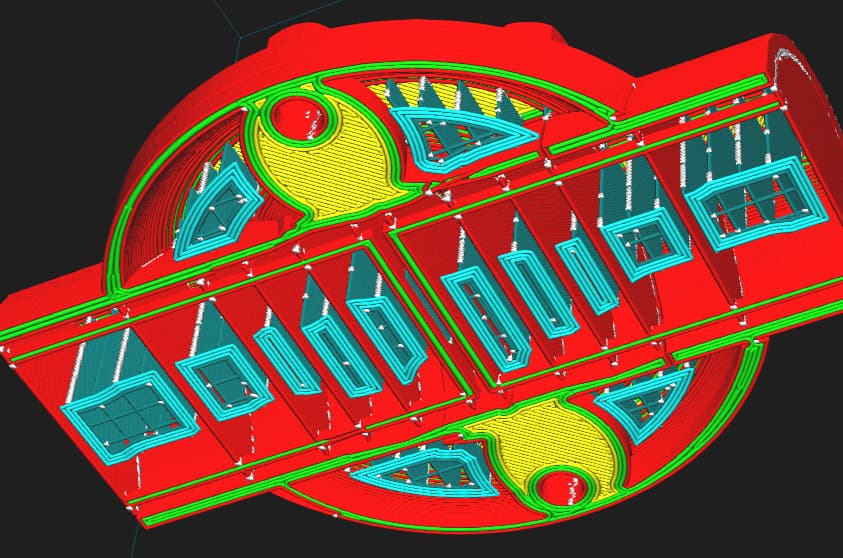

Next Cura, I haven’t used it for about a year now. Fresh dnld, vanilla settings - had to got to work so no time to tweak anything.

Dang! Does that look nice or what?

So how does CP compare?

What’s with all the gaps? No wonder prints are getting trashed-CP9904 - Customer Problem V5.1.2.9904

I reviewed a bunch of fails and they trace back to this load of (Insert Nasty Thing Here) !