Hello,

More often than not, printing any model (small or large) with Ender-3 V2 Neo fails because of warping.

Since the beginning it was obvious that no model could be printed successfully without a Draft base. Now, a couple of months later, models fail to be printed even with a Draft base. The problem is that whatever is printing eventually moves (warps?) on the bed plate even though a Draft base has been printed.

Printing a Draft every time is both time and fillament consuming. I’ve tested with various printing speeds (50, 70, 100) and temperatures (both for the nozzle (210-220) and the bed plate (75, 70, 80)) to no avail. I’ve also replaced the nozzle head with the spare one. I am using CREALITY and ENDER PLA fillaments (white, blue, yellow).

Is there anything I can do to fix this? I hope this is not standard for this kind of printer; if it is, then the printer is pretty much useless and just a toy.

Thanks in advance,

1 Like

Make sure the print bed is super clean, wash in Dawn/Fairy dishwashing liquid and water, dry and then wipe down with isopropyl alcohol before every print. For PLA the bed plate shouldn’t be higher than 60°C preferably 55°C. Make sure there are no draughts from doors/windows and most importantly make sure that first layer is properly squished into the bed. Could you show us the first layer it can show up areas that need addressing.

1 Like

To add to what bonfireman said:

The amount of internal stresses will depend on the geometry of the part. In other words, you can alter the design to allow these forces to dissipate by adding slots

If you’re familiar with welding and the force from shrinkage of welds, it’s much the same concept

Another idea is to orientate the part at 45 degrees so that less area is touching the build plate. This has the nice side effect of requiring less supports

Print with a brim too and if it is an old build plate scuff it up with some 1200 grit wet/dry sandpaper.

1 Like

Thank you for your replies,

the plate is a bit scratched because we were using the blade that came with the printer to detach the printed models, initially.

What you said about the plate temperature being 55-60 degress for PLA sounds impossible to me; we have never managed to print anything with a plate temperature below 70 degrees.

I will try to upload a photo of the plate and I will certainly try to clean and scuff the plate with sandpaper.

I will let you know.

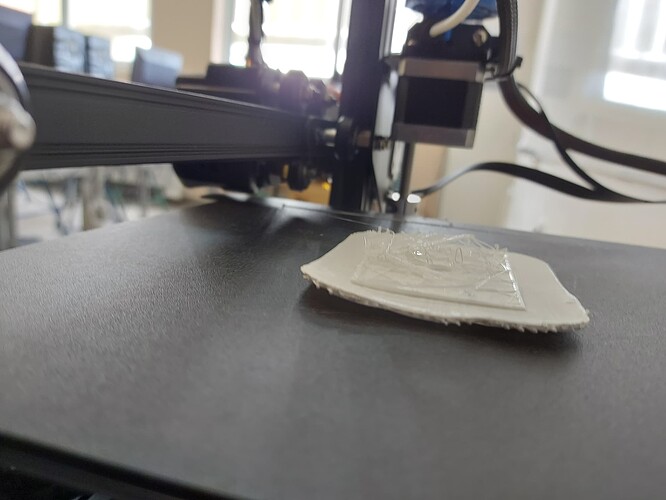

Here are two photos of Ender3 v2 Neo printing the Raft for this model: 3D Printer Files | 3MF File | 3D Flexi Baby Dragon Keychain (Limited Time Free) UniQrint | Creality Cloud

The settings are:

Printing speed: 100

Nozzle temperature: 200

Bed temperature: 70

Build Plate Adhesion: Raft

We’ve tried many times with the default settings (Nozzle temp: 200, Bed temp: 60, Build plate adhesion: Skirt) but to no avail. It starts warping right away.

I will follow-up with photos of the failed (warped) print.

It looks like it is going to print it after all.

Settings:

Printing speed: 50% (100% for the Raft)

Nozzle temperature: 200

Plate temperature: 70

Also, I am keeping the room temperature at 20 degrees with closed door and windows, which seems to be effective.

@Bonfireman Here are photos of a Raft and a model that failed too soon. You can see the Raft is not properly squished into the bed and the printer failed to print the model early. I also attach a photo of the bottom of the Raft.

The printing settings:

Speed: 100%

Nozzle temperature: 200

Bed temperature: 60 (as you suggested)

Unfortunately, this is how Ender-3 V2 Neo behaves since day one.

Any conclusions based on the photos?

The filament is too high and not being squished into the bed or the bed isn’t properly cleaned.

Thank you for your prompt replies.

I’ve got it cleaned and scuffed. Also, I set nozzle/plate temperatures to 200/60 for PLA.

Works much better now.