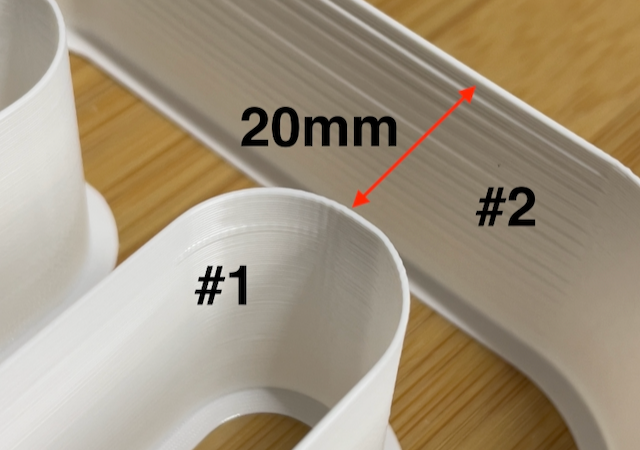

Hello. I need help with my K1C. Ever since I got it, I’ve only printed models that didn’t require much dimensional accuracy or that fit together properly since their dimensions were always under 100 mm. At the beginning of December, I started printing a cabinet I designed, made up of 38 pieces (the project can be downloaded for free here ), with overall dimensions of 650x430x200 mm. The largest pieces have sides measuring about 200 mm. That’s when the problems started: the pieces don’t fit together, the sides aren’t parallel, and as the piece approaches the back of the build plate, the horizontal dimensions shrink by up to 2 mm.

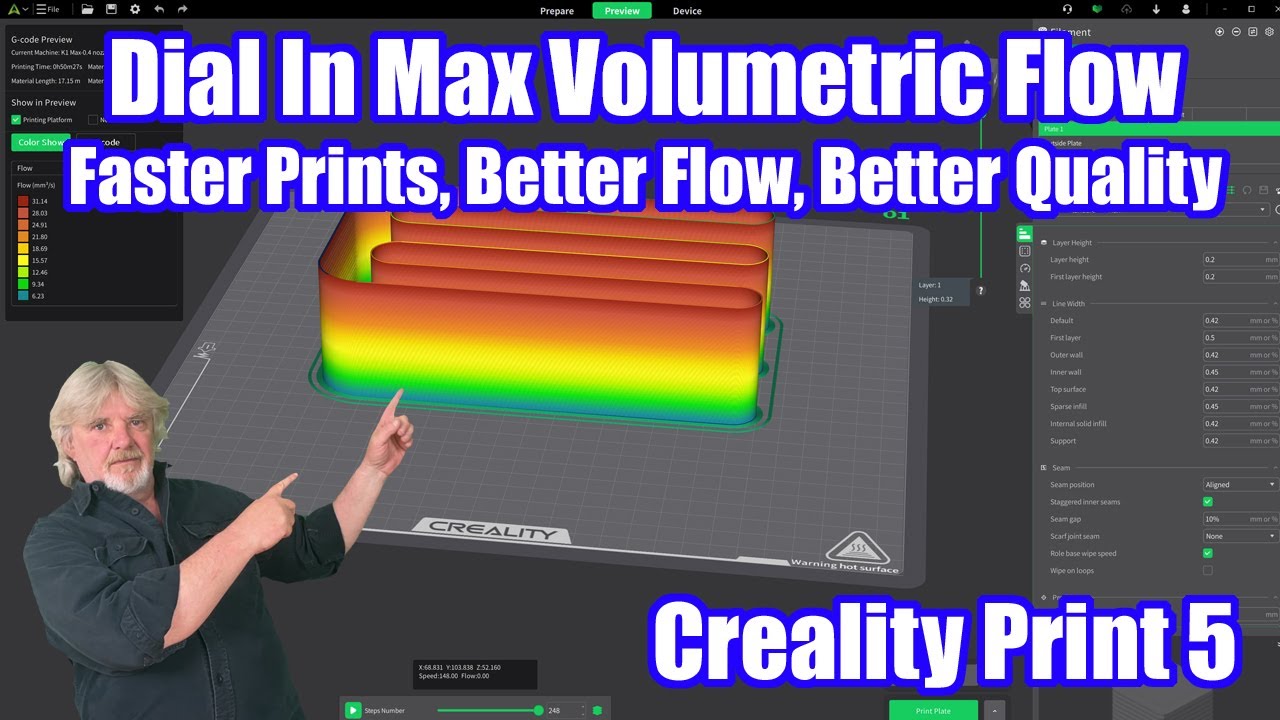

In addition to this, I’ve had issues with over-extrusion on the first layer and under-extrusion on the top layer. I’ve spent hours calibrating temperature, flow rate, pressure advance, Z-offset, skew, and retraction. I’ve changed filaments (Creality Hyper PLA, Anycubic Hi-Speed PLA, Sunlu Hi-Speed PLA, Creality Ender regular PLA, and Anycubic regular PLA). I’ve replaced the nozzle (0.4 mm) with a new original Creality one for the K1C. I’ve lubricated all the axes, cleaned the extruder, calibrated and recalibrated the belt tension, and even bought a Biqu belt tensioner. I printed a 0.1 mm spacer to adjust the print bed leveling since there was a 0.27 mm difference between the higher left side and the lower right side. I’ve also updated the firmware and done two factory resets with initial auto-calibrations. Nothing worked.

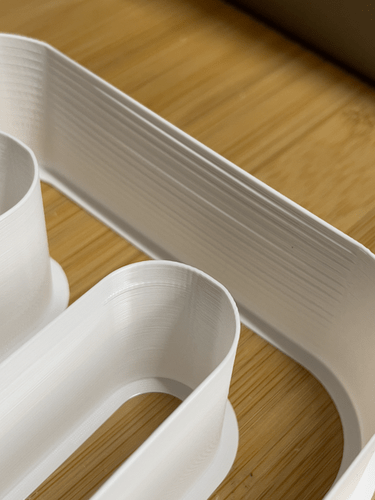

Apart from printing squares as trapezoids, calibrating the flow rate has been impossible. Tests suggest I should set the flow to 107–110%, but of course, when I set this flow, the first layer prints well, while all other layers are heavily over-extruded. When I keep the flow between 98% and 102%, the top layer ends up being severely under-extruded, to the point where I had to apply a significant amount of acrylic filler to the surface of parts like the cabinet doors because they are full of gaps between filament lines. Assembling the cabinet was a nightmare—I had to use four tubes of acrylic filler to close the gaps between the pieces (as I mentioned earlier, they aren’t squared but trapezoidal).

I don’t know what else to do. I’ve contacted Creality support hoping they’ll replace the printer. Ironically, my Kobra 2 Neo, which I paid €150 for, after few tweaks is far more reliable than my K1C. Help!