Hello all.

I have had my printer (Ender 3 V3 SE) for about 3 months now. I noticed right away when I got it, that their seem to be a problem with it. I could level it auto/manually and go back and check a zones after leveling others and it would not be right. However, after observing this behavior, I quickly learned that I could not make any changes to the zone, leave it and go directly back to it and it would be differnt again (usually some what where I had it leveled at).

Seeing that this is my first 3D printer and I am still learning, I more less chalked it up to “I don’t know what I am doing, yet”, and moved on. By moving on, I mean I figured there was nothing wrong with the machine, it was just me.

However, here I am, about 3 months into this, countless hours of research, video after video, article after article and almost 2 full spools of PLA Filament (Creality Hyper), and the machine is worse than it was when I first set it up.

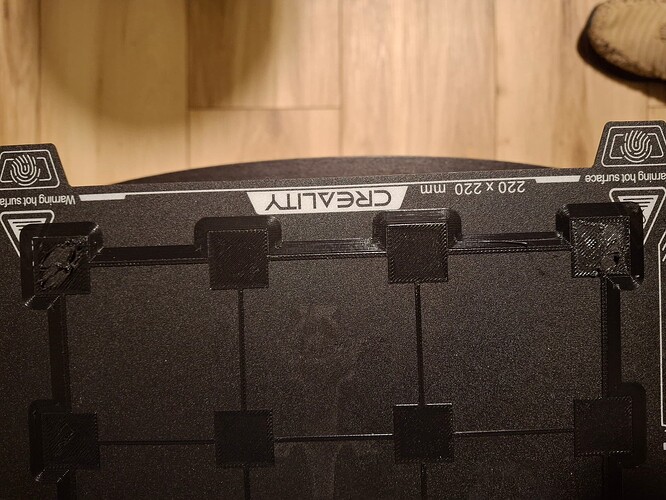

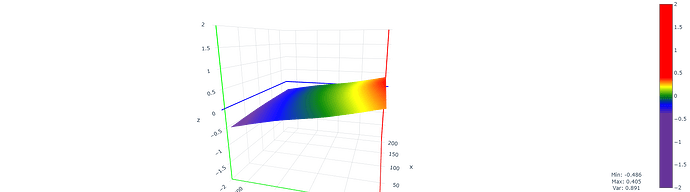

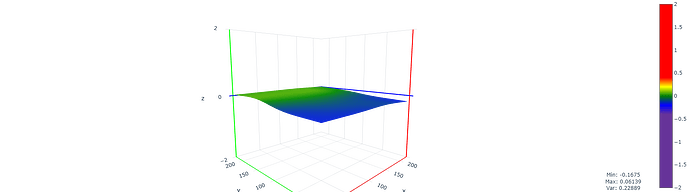

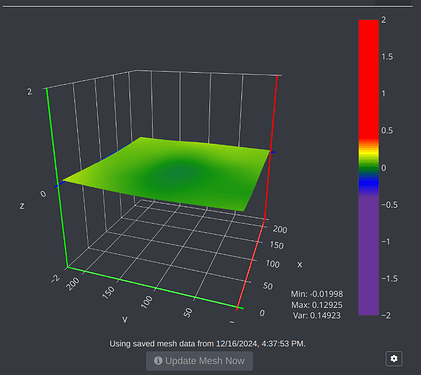

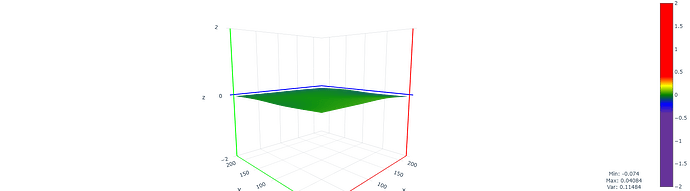

So, here are a few things that I have done (some repetitive). I have used about ever slicer that I could find, I have printed calibrations and adjusted the settings in every slicer. I have done the bed leveling (both auto and manual), until I could just about do it in my sleep. I have flashed the firmware for both the portal (control unit) and the mainboard. I have tried adjusting the levels by site and feel of the one layer prints. I have setup Octoprint and used the tools (visualizer) in that to try and adjust and correct things. I have taken the bed up and took the hot plate off to see if the cstructure it is mounted to was defective. I was not able to make a for sure judgement, but it did seem that it was tilted upwards in the front. After that I made sure to tighten things to a good snug. As well, I had checked all the seeable screws long ago.

I am to the point that I believe the machine if defective. Here is my main stay in that statement. When I move the print head to zone A and that zone is set for 10 and the machine moves the print head to the zone but, it either stops short of the 10 (i.e. say 15) or it goes past it (i.e. -5). I don’t make any adjustments, I just click to have the print z back up and then I click edit again and go right back to that zone and the print head stops in a completely different area (most likely the correct/calibrated area). This tells me that the machine isn’t getting the axis right for some reason.

With all this being said, I have tried to find a phone number to call from the states to support and I have come up short. I sent an email pleading for someone to call me. So, we will see what happens there. In the mean time, if you have any suggestions or ideas, please, by all means let me know.

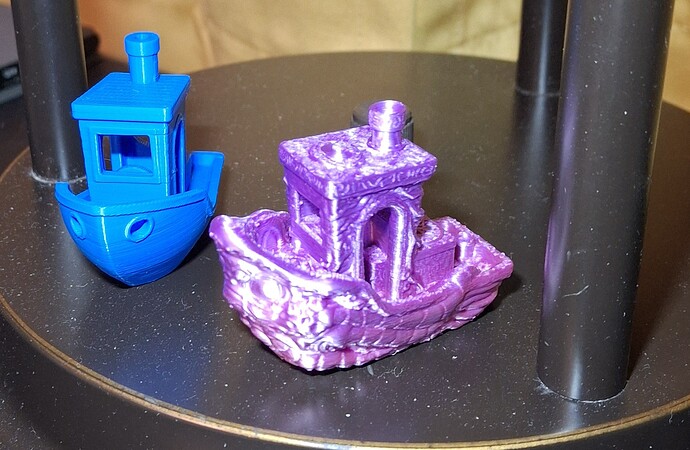

BTW: I am going to try and attach some images of what happens on some of the bed leveling prints.

Thanks for reading this and hopefully I can get this matter cleared up ASAP.