I’m sure I’m not the first to think about this, but I haven’t seen it yet anywhere and I’m happy I thought about it ![]()

This week-end while shopping at Walmart with my wife, we saw these vinyl rolls that are used in vinyl cutter machines. We always wanted to get one of these machines to play around with - you can create really nice things with them.

So, looking at the roll, I told myself that this is probably something that my Falcon 2 22w could do easily! …read on to find out ![]()

For reference, the vinyl I’m talking about is this exact roll I bought at Walmart, but that you can easily find online or in craft shops - Cricut Smart Permanent Vinyl (13in x 3ft, Black) for Explore and Maker 3 - Matless cutting for long cuts up to 12ft : Amazon.ca: Home

I started by cutting a small strip from the roll so I could make tests.

That brought the first issue - being rolled up, the strip was all curled up. I had to work hard to get it uncurled so it could lay flat on the bed. I didn’t want to have the parts starting to curve up once they were cut!

Once I got it flat, I created a cut grid in LightBurn - I always design my own because for some reason, I can never get the built-in laser test tool to work. So, I started with values I thought would work, based on tests I did on a regular 20 pounds sheet of white paper (which by the way works great!).

I was lucky because the values I’ve put in were just great: 3000 mm/minutes & 80% power. The nice thing is that this setting only cuts the vinyl, leaving the back sheet almost untouched! Way easier to remove the cut parts, and it makes it all stay together. Other advantage is that the cut parts won’t start curling up if you didn’t get the sheet to be totally flat.

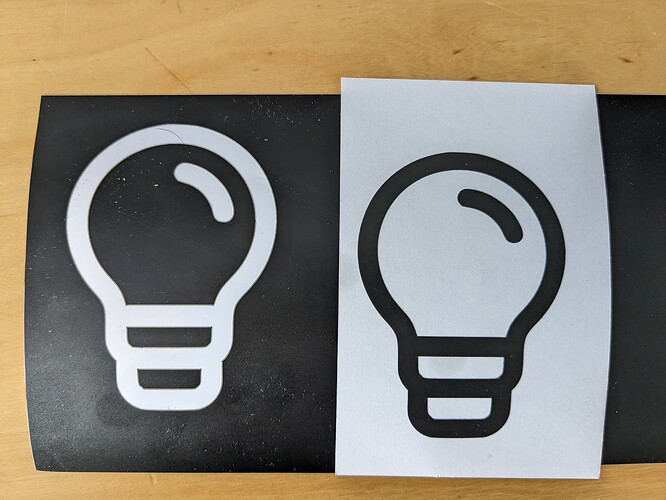

In the image below, on the left with the black background is the sheet of vinyl. The white sheet is the cut-out model transferred on a piece of paper (you can see the vinyl is still curled up a bit!)

The cut is extremely precise and gives a fantastic result!

Couple notes here:

- It smells really bad while cutting, so make sure you have good ventilation

- The speed/power will most likely have to be changed if you use different colors, or even a different brand. You can however use this as a starting point.

- Even though the curl in the paper can be worked out, you might have it easier if you buy the vinyl in sheets instead of rolls - there are plenty to choose from online or at your craft local store.

- You could make yourself a frame to put on top of curled up sheet so it would help it stay flat - you’d cut inside that frame

Another success - It opens another whole set of possibilities with this wonderfull tool!

Enjoy ![]()