When 3D scanning meets 3D printing, your creativity is no longer limited by modeling skills.

Scan + Print has become an efficient tool for more and more creators, DIY enthusiasts, and designers.

This time, we invite you to help us recreate the items you want to print but don’t have models for:

Discontinued but essential parts?

Broken pieces that are hard to replace?

Or a sculpture that holds precious memories of loved ones?

The prize?

1. Creality Otter Lite 3D Scanners x3

2. 50 USD Gift Cards x3

To participate, simply visit the giveaway link, tell Creality what you’d like to scan and print, and unlock bonus entries to increase your chances of winning.

Don’t miss out on this chance to bring your creations to life!

Join now:

https://gleam.io/competitions/p2H16-win-free-creality-3d-scanners-what-would-you-scan

4 Likes

I would scan head shots of my children and then scale them down to a reasonable size for keep sakes and display. They grow up fast and their facial features change as they age.

2 Likes

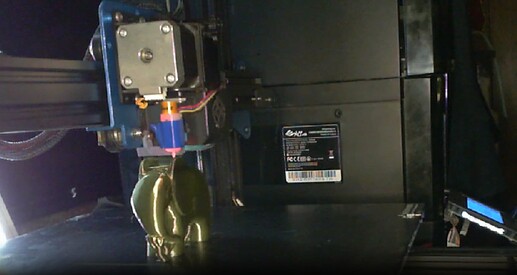

My latest Scan-and-Print with my Creality Otter, was for my grandson.

He really likes this hand carved wooden elephant toy. however he is autistic and will sometimes thow toys. So we thought it would be safer for him to have a smaller lighter model. So I scanned and printed this at 60% scale. He just loves it.

I don’t have a Creality printer (yet) but very close. It’s a Sovol sv03 that uses a Creality 2.2.1 board and all creality steppers and such with a huge 350x350 glass bed.

I used Creality Scan 4 v1.0.3, and what a lovely expeirience. Such nice impovements in the software of late.

Sliced with Creality Print 6.0.2 beta, also some great improvments.

and Printed with Klipper in Polymaker Silk Peridote Green

1 Like

Im a pro-woodworker who is also the workshops tech nerd.

I’ve been using my tasty Creality K1 Max to print a HUGE RANGE of dust-collection attachments, bell mouthed housings, blast nozzles, and fix parts that break on the machines (using ASA, Nylon and TPU).

I would use the scanner to scan the insides of all the sites machines in order to make custom dust collection shrouds for their internals.

Better dust collection = better worker health.

Secondly, I would scan out handheld tools to more accurately model the shrouding to collect dust, add grips and additional handles. Sanders especially are bad - by making a tight fitting shroud that is customised to fit the tool perfectly would be a dream.

Better ergonomics =happier workers!