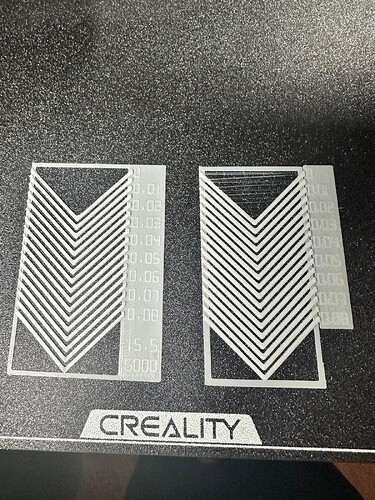

My eyes are messing with me and I’d love some more on these if anyone didn’t mind looking. On the left, that’s the default PA calibration from orca slicer. On the right, I used ellis’s gcode. Thanks a lot in advance again, this group is terrific and I appreciate the knowledge.

Thanks a lot, but I meant more which line/value on either PA pattern test ![]()

I would go with 0.05

It’s when you have the most balanced rounded corner. Not excessive nor thinner

Thank you. I was under the impression the corners had to be pointy, which is why I had an impossible time choosing as you can imagine!

It can never be pointy because of the nozzle pattern which is a circle. The goal is to have same width throughout the line so that the final shape won’t affect the dimensions of the object ![]()

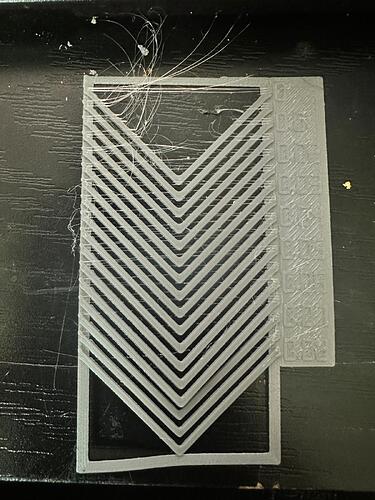

Sigh that makes so much sense. I took “sharpest corner” in a literal sense. I think I’ve been so hyperfocused on trying to get this thing to print well since the start that I’m just all sorts of clouded. Just to compare, I loaded in another filament brand, color and class I suppose (PLA vs hyper PLA). Would you say 0.06 is the mark here or am I off?

Hello Kris_Bee,

It looks to me that your filament needs drying, which would reduce the possibility of the stringing along with give you a better print result to work with.

Cheers.

I’ll give that a shot. I just watched 3 PA tests with smaller increments completely fail. I’m watching a vanilla orca slicer flow rate calibration drag spaghetti around the bed. I’m really starting to lose hope here. I regret going into debt for this printer deeply at the moment.

Regarding PA, I would go with 0.03.

On another note, I see something in this photo that it is concerning: are there scratches on your bed surface, to the left of the print that I’m seeing or is it just my old aged eyes?

Also, please bare in mind that a 3d printer is a tool. As with every tool, we must understand how they work, what it is required for them to work (dry filament, clean bed surface, etc) and what we must do to keep them working (maintenance)

Thankfully that is my wooden desk and not my bed but thank you for even caring enough to point it out! ![]() 0.03 really wow alright. I just printed out these flow cubes after having set the PA to 0.05 and the results are significantly better. My plan was to read the job log and find out what auto-calibration of the PA was found to be and then set that for the filament if that’s a good approach.

0.03 really wow alright. I just printed out these flow cubes after having set the PA to 0.05 and the results are significantly better. My plan was to read the job log and find out what auto-calibration of the PA was found to be and then set that for the filament if that’s a good approach.

I’m so happy that that wasn’t your bed surface.

On another note, you might want to check this post regarding filament tuning. Make sure you check the included links as well. They might be an eye opener for you as they were for me ![]()

I actually went and started at the beginning with extruder calibration thanks to a dear friend and something very interesting happened - as I’m extruding, my white filament was showing tinges of orange. Knowing these things don’t just happen magically, I suddenly recalled that I had tested some PC weeks back and never ran it again after. I also hadn’t cleaned the nozzle because who really does that religiously as they probably should :). That being said, PC needing about 265C to melt, and me not running anything that even went near that, I’m sure there was plenty of PC residue in there that didn’t melt away until I intentionally cranked the temps up once I saw that. Now, my extruder is calibrated and 100mm requested == 100mm extruded. Flow rate and all of that are much cleaner as well as printing so far. The journey as you well know, however, is nowhere near through with calibration but this was an incredibly fortunate ‘mistake’ that exposed a gremlin that could have lived in that extrude for ages to come. ![]()