By which you should know I mean the underside of prints…sigh …if you’re here for any other reason I despair…

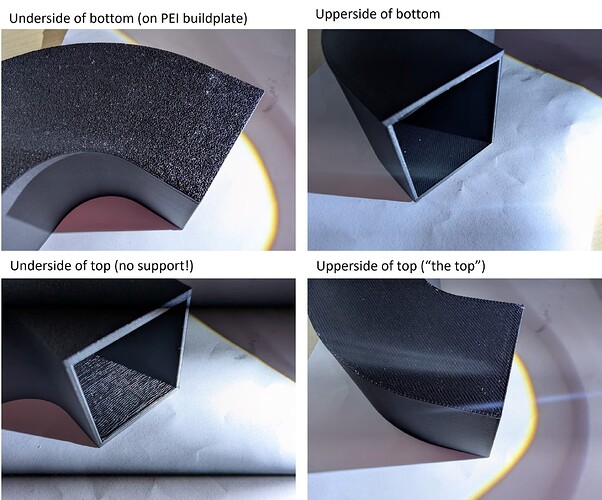

Getting a good top finish is easy these days…and getting a good underside too - gloss or that nice PEI texture if you’re on either glass or the build plate.

But anything in contact with support (shudder) or worse still, completely unsupported has always been a loopy, stringy, dog-rough nightmare.

Until now. For reasons I wont’ bore you with (yet) I wanted a box section, 40mmx40mm, with a 2mm wall, floor and roof; effectively a 40mm square pipe.

And The K2 Plus just…did it. I mean granted it’s the worst of all four horizontal surfaces created…but…I’d have danced a little jig to get that sort of finish on a 20mm bridge on my old CR10s Pro (using Cura).

My question is; is the improvement (the VAST improvement) due mostly to hardware (the new K2), software (the Creality Slicer) or materials (Hyper PLA)?

The four surfaces of my square pipe;