Just trying to print something with a color change at a certain layer.

Slicer generated M600 as the G-Code for color change, but The printer is not impressed an didn’t stop to change filament. So what do I need to do to switch filaments a a certain layer on the Ender 3 V3 Plus?

Tried out Creality Print on Windows to see what it would do, but that does not even offer a filament change option. Nevertheless, put a PAUSE there and that worked just fine. Printhead is moving to a parking position so you can remove the current filament and insert a new one. Problem solved.

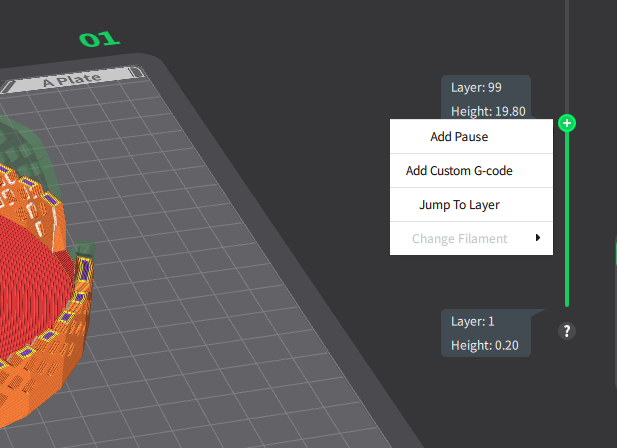

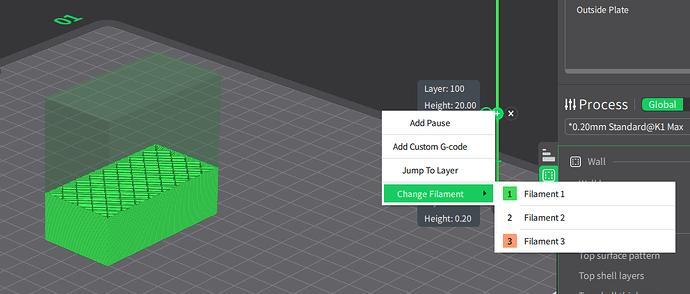

Creality Print 5.xx has a very simple way to add pause by right clicking on the slider as in the picture here:

I just got my Ender 3 V3 Plus 2 days ago. I’m still learning Creality Slicer, which seems to be not too bad. I’m used to Cura, so there are some major differences for sure.

But now I’m concerned. If I’m understanding rakoenig correctly, he/she was saying that M600 did NOT get the 3 V3 Plus to stop for a filament change.

That concerned me as that is a thing I like to do with some of my prints.

So, my curiosity got to me, so I just ran a test where I inserted M600 codes at layers 26 and 36 (keep it low to test) LOL

NEITHER WORKED!

So using the Windows URL into the printer, I pressed pause and the printer paused.

I waited a few seconds to confirm something, then resumed it.

Honestly, I did not like how this worked. It did work, but… .meh… I don’t know that we can trust it to return to the layer proper if the gantry moves down a bit when trying to change filament.

After all, we have to remove the PTFE but to make the change, unless just cutting the first filament and pushing in the next color, keeping it up against the 1st one as it travels up the tube.

I wonder if the Creality devs are aware of this. Being that it’s Klipper, one would think that M600 should just work… but it does not.

The concern with pause, as I’ve confirmed, is that pause turns off all heat. When unpaused, it doesn’t appear to wait for the nozzle and bed to return to operating temperature. More tests are necessary.

For one thing, as the days go on, I’m going to put 2 spool on the top rail, move the filament sensor to a better position, centered I think, with a very short travel to the spools. Then, on the extruder, just a very small, perhaps 4" PTFE tube (like on my old printer).

That would make filament changing easier.

On my Ender-3 V3 Plus (stock) when using the pause function in the Creality Print 5.xx slicer:

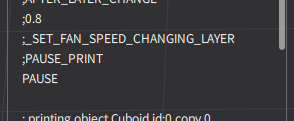

It adds the pause command:

The extruder moves up a couple inches and over to the right side.

The build plate temp stays on..

The nozzle temp cools to 140°C.

After pressing resume the nozzle temps heats up and then continues the print.

Thanks for that. I’ll give that a try tomorrow.

I have to learn how to make other “filament” choices and see them in the list as you’ve done there.

When it pauses, though, how do you do the change of filament?

Meaning, do you unlock the little leave, then pull out the filament before it gets stuck?

I’m also concerned about having to touch the gantry, because I’ve noticed with mine, even the slightest touch it moves up or down, depending on the very light pressure on it.

I’m not if it would do that in pause mode or not. I’ll test that tomorrow. Perhaps with some luck, the pause mode will lock the motors so that the gantry can’t move at all.

If it does move, I don’t think that the print job will finish as the nozzle may not be able to find the position it left off.

There doesn’t seem to be any homing at all… so any gantry move could spoil the print.

Apparently, there is a start/end macro (or something like that) that tells the printer what to do if it sees an M600 (which I discovered, Klipper doesn’t know)… but I have no idea where or how to put the macro, unless it’s just in start/end areas.

More research is required.

When it pauses, though, how do you do the change of filament?

When the printer encounters a PAUSE statement in the GCODE it moves the print head up and to the right, the bed will be moved to the back so that you can acess the touchscreen.

Then do as usual when you change filament:

- Go to the settings screen with `extrude/retract/ and chose retract

- When retraction is done remove the filament from the teflon tube.

- Your filament runout sensor will trigger and you will se a warning on the display, don’t worry about this.

- Insert the new filament as usual.

- Press “continue” for the filmanet runout warning

- Select “Extrude” to extrude the remains of the old color and a bit of the new color.

- Remove all the extruded material

- Go to the “Home” screen on the touchpad and press the icon for “play/stop”.

- Then press continue

After this it will take a while because the nozzle needs to be heated up again. Then the printer will resume printing.

Don’t worry, the steppers will be locked, so after resuming the print, the printer will go on where it stopped, no layer shift, just perfcect print with a second color.

Thanks for the logical steps. I still haven’t gotten around to it because I ended up buying a 2nd 3 V3Plus and had to move my old printer out of the lab and set up the 2nd printer.

I do wish, however, that Creality would change the pausing code in that the bed’s heater is not shut off.

My concern is, since it’s the heat that keeps the object stuck to the bed, if it cools too much, it may actually pop off when the print starts.

But again, I haven’t had time to try it.

I just remodeled a top spool holder to make it hold the spool frontwards instead of backwards.

Today, I have to make 2 extension wires with connectors to move the runout sensors to the top.

I love these machines, but oh how I HATE this side spool thing!

But, I’ll give it a try. I considered putting 2 spool holders on to hold the 2 colors I would want to change to, but then I thought, that’s just too heavy for the frame. Unless I put one facing backwards and the one facing forward to balance off.

Either way, the spool holder mounted to the frame is just temporary.

I have the materials now to make stand alone spool holders that would just sit on the tables, beside the printers.

When using the pause command as I described earlier doesn’t turn the build plate heat off.

Sorry about that. I did misread the above comments where it does clearly state that the bed also stays hot.

That is great news then!

Thanks so much.

So here’s the problem I have with using pause for filament change. The pause itself works, and I can go to the LCD screen and do a retract. Then I can change the filament and go back to the screen to do an Extract. All is well at that point. But when I resume printing, the extruder deposits a blob of filament onto the model as it resumes!

Does that happen to anyone else? This is an Ender-3 V3 (no plus, no KE no SE). It has a print head and extruder like the K1.

Hello @Wilywit …! ![]()

Welcome to the Creality Forum…! ![]()

Mine does once in a while leave a little piece or string but it’s easily removed.. Not a lot but a little annoying..

If I’m watching it I can pull the piece off the extruder before it gets to the model..

I have Plus and this did happen once.

Then I realized, I need to follow the right path.

- Set pause at layer in slicer

- When printer pauses and moves head away, like you did, do a Retract.

- Then, insert new color, but now, do an EXTRUDE!

Once the extrude is done, the filament shouldn’t drip out at this point.

Then, resume.

I’ve followed that ever since and now, never an issue.

Perhaps that’ll work for you???

Guys, can you confirm that when you add pause in Creality slicer, as you described above, printer is stopping? I have a feeeling that after last software update this feature is no longer working. I’m adding pause, hit button print and there is no pause at all during printing. Do you have the same ??before it works perfectly

Hello @rozr111 …! ![]()

Welcome to the Creality Forum…! ![]()

What version are you working with…?

In Ver #5.1.4.10249 the pause works for me on a K1 Max and Ender-3 V3 Plus… It’s not the newest version..

You’ll have to test another version first and make sure it works..

I’m using 5.1.6.10470

Try going back to the last version. 10249

and try again this way…

I’m not sure why it’s not working for others… ![]()

Hello,

I have not tried color change but am curious about it, hence this question.

If say you have a print that will take 2 hours to complete and you want a color change at the 3/4 mark and set it to do the pause at that point, how do you know when it is at that point ?

Can you set it so that you get an alert, or do you simply guess when to come back and check, or only go away for about 1/2 an hour then come back and watch for it ?

Hope this is a reasonable question.

Cheers.

I’m not the best at explaining so I’ll try here. Someone else maybe a better wordsmith and can help more but basically you check in your slicer where you want the pause for the color change to take place. You set it at that layer.

If your print is 100 layers you scroll the slicer to see where the color change will be. It takes a little practice so maybe use a cube or something to practice on to make sure the printer will pause.

There is no alert or anything. The printer will pause and wait for you. You just have to monitor it’s progress… I tend to babysit the printer and check on it once in a while…

Now if you have machine with an Color system like the K2 Plus it will automatically change the color. I

Additional question, when you will slice the model, then you will add a pause, then you need to slice again or not ??