Hello Creality team, I have the first CR10S Pro V2 printer and it is a fantastic printer that gave birth to many children, such as Vorons. I have printed a lot of things for 2 years and I have a question: what is the coating of this bed made of? Not this glass. This one is glued to an aluminum plate. It’s great because you can work in eco mode without heating the bed, and I’m looking for a sticker like this. Please help!!

Hi @Greliusz and welcome to the forums.

I am not 100% sure what the coating on the stock build plate is but its likely to be something like PEI/PEX coating on a magnetic steel sheet.

Most people tend to use the PEI smooth or textured plates these days which also attach to the printer via the magnetic grey pad that is stuck to your printers build platform. Most build plates do come with a replacement adhesive magnetic pad but if your printer already has one fitted then you wont need to fit it.

Hope that helps.

That’s what I’m asking because most people have the same answer as you, because they are used to the current situation with PEI coatings and magnesium beds. I bought a printer in 2020, where there was no mention of PEI/PEX and they were in unwinders. And you’re right that you’re not 100% sure. The bed is not made of glass, it is not painted, it is glued to an aluminum plate and attached to the table. You don’t have to heat the bed and you can even print on it, because this printer has an eco mode and the bed automatically turns off after an hour of work and continues printing, it still holds PLA and PETG. This was the case at the beginning of promotions when Creality offered the CR-10S Pro V2.

I don’t understand you, if you don’t know, why are you answering my question? I asked the manufacturer a question. My question is simple: what kind of coating is that on the original table - let me emphasize that it is NO PEI, NO SHEET!!

First of all this is a community driven forum, it is VERY rare to ever see a Creality member of staff in the forums therefore as a forum moderator my role is to keep an eye on the forums and assist whenever I possibly can. I would much rather offer a response to a forum post than to just ignore it. I am sorry if you feel this is not appropriate.

Secondly you have not provided any photos of this supposed bed surface that you are referring to. It would help considerably if you were to provide a picture of said surface so we know exactly what part of the bed you are referring to.

Thirdly please do not be rude by CAPITALIZING words to attempt to force your point across. We are a friendly community who enjoy helping others and working with others to try and come up with a solution or answer.

I appreciate that I may not have provided you with the answer you were looking for but that does not mean that you need to be so dismissive. I went out of my way to attempt to track down what the bed coating was and reported back my findings. I am sorry that this does not satisfy your request but I am merely trying to do my best to support you.

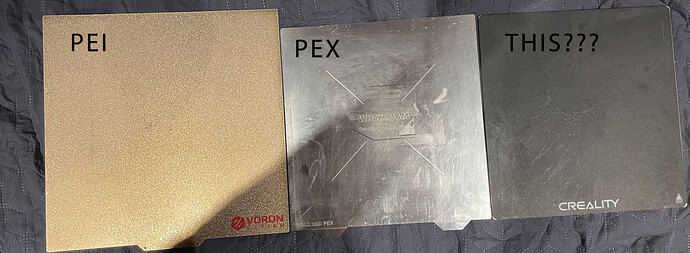

You’re right, I could have uploaded photos - I thought that a description and a specific printer model would be enough, but this printer has never been in your offer, made of a PEI/PEX table, etc. As in the photo, it’s the original plate - I’m interested in this coating, it’s glued on an aluminum plate .

I want to know what type it is because for me it is a fantastic thing, it holds very firmly even when the table is not heated at all.

You don’t know what kind of coating this is?

From the information I have gathered the coating of the plate is most likely a PEX coating. You would need to contact the manufacturer for 100% confirmation.

It’s not PEX - I know this because I have a board from WhamBam installed on this printer. Ok, give me the manufacturer’s email. I thought Creality was responding to the forum… it has the creality.com domain, strange isn’t it?

It’s a Creality forum @Greliusz…! ![]() There are many users here who will try to help you just like other forums run by different 3D printer manufacturers. The users are the ones out here taking the time to answer your questions. They have some valuable information to share and if you don’t like the answer remember that person tried and spent some time researching it for you.

There are many users here who will try to help you just like other forums run by different 3D printer manufacturers. The users are the ones out here taking the time to answer your questions. They have some valuable information to share and if you don’t like the answer remember that person tried and spent some time researching it for you.

You can also do some research on your own to get answers like we do and share with the rest of the group as someone might have the same questions as you do…

Try joining the Creality Facebook groups to get an answer also.

You know why this annoys me? It’s been almost a month now, I’ve asked everywhere and everyone gives the same answer - they don’t know the answer - they have codes for this new technology, such as sheet metal. I’m surprised because Ender 3 is already 6 years old, there are many versions of the bed, and this coating from CR-10S Pro V2 was once a novelty - therefore PRO, much improved from the first version of Cr-10 and in larger sizes, and no one wondered what is this material? Cr10 Max also has the same coating!! Let me tell you: WhamBam cooperated with Original Prusa and presented this sheet metal with a special coating plus a magnesium sticker. Other manufacturers followed suit and now each manufacturer provides the exact name and what it is made of. People have coded this time period for themselves, and no one knows what happened before?? Previously, the printer worked on glass or ordinary painter’s tape. But no one knows what the special black coating was, which used to be standard on cheaper printers, there was no need to inform about it because it held strong and everyone was satisfied - something between the glass and the “fashionable” plate, as I described, is glued on aluminum plate 3-4 mm thick. It is replaceable, held on caps that you attach to the table. Made for people who save on electricity because they can print without heating the table. This was fantastic for PLA and PETG. Nobody knows! I know that every user on the forum produces for the number of posts. They talk about nothing, ask questions and pretend to be “experts”. I know they tried to help, but they didn’t answer this question, it was clicked, we have counted posts about nothing. “Maybe PEI? PEX? Maybe glass?” I’ve heard that before. I have the impression that even Creality doesn’t know either and they sold the printer! Thanks for trying xD

What you just did was share a lot of valuable information that most of us didn’t know. You are an expert in that area. Thank you. ![]()

Just because no one knows about this as much as you do I don’t think it’s fair to bash the forum and other users by saying basically we are all fake. I think if you read for awhile you will find a lot of helpful comments not just for “the number of posts” but to actually help other user.

Look to picture - it’s a simple matter. Do you recognize it? No, then why are you calling? Does this look like PEX? Do you know what the PEX coating looks like and how it works?

The guys marked “EXPERT” replied that it was PEX, so I felt bad. I don’t know why he wrote this? Please understand this!

I asked a question because I’m curious what material this Creality inscription is. I’m the 5th person asks, they have used materials, had a damaged coating, they don’t want to buy PEX/PEI, they only want THIS - the black one. Me too. Over time, I have come to appreciate it more than PEI/PEX. I don’t want glass. I hope you are part of the Creality team, on this forum, ask questions, doubts, give answers, criticize and be humble, to be better for the future. Original Prusa has so many enemies, but they can handle this support. Prove it! I’m not attacking you.

He answered your question as best as he could and told you to contact Creality.

I’m guessing you don’t want anybody to talk to you or help you at all unless they know the answer which is fine.

Did you know that you can also do some research on your own.!! ![]()

I don’t know the answer but I can steer you in the right direction…

Send a nice email to them.

If someone sees your question on here and wants to answer or help you after making those remarks… Good Luck…

I see that there is no answer. This forum loses its meaning and u send it via e-mail where it does not respond to e-mails at all - like the Soviet Union. Good move, gentlemens ![]()

If I find the answers, I will write here, at least I can help and educate you xD

To further clarify something… Creality staff picked us to be forum experts, we do not allocate the name to ourselves.

Please also keep political views and opinions off of the forum. This is a place to discuss 3D printers, not politics.

Please also refrain from being condescending or rude as no one will want to help you if you continue with that attitude.

Thank you for also stepping in and clarifying a few things @jimandyen it is very much appreciated!

I’m not rude, I just hate guessing, giving answers at random, it was enough to simply write “I don’t know” and ask them how if they chose you - why refer me to them if you have a close path to them? What is this forum for? Everywhere on the Internet, mentions or reviews about this printer - no one writes about the advantages of this coating, this bed - I explained to you that there was no fashion, there was no point in explaining what type of bed it was. Now I appreciate that it is a huge thing for people who have problems with power outages - sometimes we have a power outage for 3 hours and then you come back and the model keeps going to bed. You continue on. This is what this printer looks like, gentlemens! Several people asked a question, it caught my attention and it made me curious! I checked online and no one asked about this! No one asked what type of bed it was - because we wanted to buy a coating to repair the damaged bed! We dont want PEI/PEX/PEO etc. because they are not suitable for this purpose. Please dont ask for a UPS or emergency power.