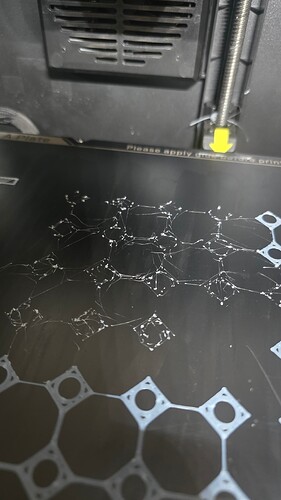

Bought a K1 Max for my business, and it has been working wonderfully, until now. I was having an issue where it would start a print okay, and then halfway through it’s first layer, would stop depositing onto the build plate. There’s an audible clicking coming from the extruder assembly, and you can feel it when you touch it.

I pulled apart the original extruder gearbox/assembly (new style), and there was a piece of plastic in it from changing filaments. Okay, great. Put it back together. Ran a couple of prints, and it started doing it again. Pulled it apart. NO plastic. Put it back together, change the nozzle. Same thing. Pull apart again, and I tried removing the extruder gears, and broke the screw that holds them on. Ordered a new upgraded extruder assembly, and installed it.

Ran the self checks for input shaping and bed level, then started the print, with calibration. Once again, halfway through the print, it stopped pushing filament through. Unlocked the filament, set the nozzle to 220, and manually pushed filament through the nozzle, and it flowed exactly as it should. What else should I be looking for to solve this issue?

Hello @Kyle_Cosgray …! ![]()

Welcome to the Creality Forum…! ![]()

Just a first check. If you are printing in PLA make sure to leave the cover off and try it.

I thought the same. I added venting top cover risers, and I keep an eye on the internal chamber temperature, and it doesn’t rise above ambient while printing. I ran it without the lid today, just to eliminate that, and it was the same.

Second thing… Other rolls of filament are doing the same thing…?

You never specified which filament you are using…

My K1 did exactly the same thing. Creality replaced the extruder and hot end and everything was back to normal…Wait for it! But only for a while. It started having the same issue again. So I set out YouTubing the heck out of it because I knew there must be something else it didn’t seem taht alot of people were experiencing the same issue. I came across a video from creality that went in to the EXTRUDE/RETRACT scenarios and there was a breif mention of the fact that you should Retract the filament when you are finished printing . Don’t let the filament cool down in the extruder/hot end. I go ahead and clean the pathway and needle at that time to be ready for my next printing session. So far the exemplified issues you are reporting and that I wa experiencing have not returned.

True; Creality Hyper PLA

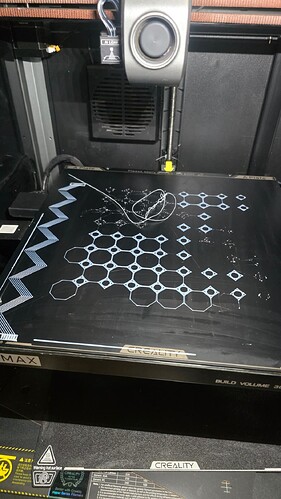

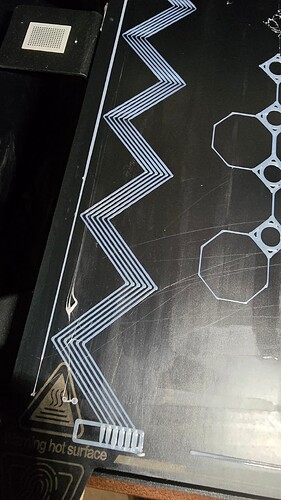

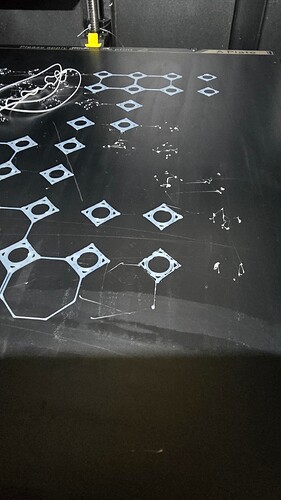

Update: It has everything to do with retraction wearing out the filament when it has multiple small extrusions to do in a row, specifically with the print I’m trying, it has a ton of little spots to infill on the first layer that it’s having to retract over and over and over again, and it gets to the point where the extruder no longer has enough contact on the filament to push it through the nozzle. I did a larger print, and it did fine, I changed some settings on the Multiboard print, so that it was only 1 wall first layer, and it did fine, until it had to do multiple small infills in a row.