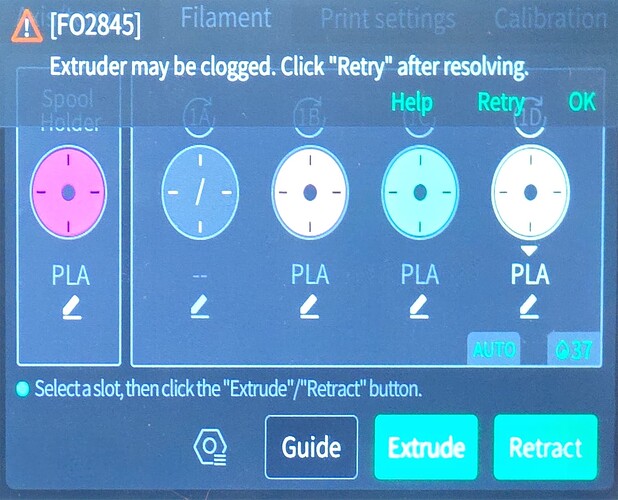

Hello, I have recently had a sudden scare with my K2 printer. All of a sudden when I loaded the Hyper PLA “Veri Peri” into my cfs a piece broke off in the nozzle and caused an error, I followed the steps to remove the piece and the printer persisted with detecting a clog in said nozzle. It got to the point where I decided to try swapping the nozzle and reconnecting the sensor, using standard white PLA that I know works I had the same clog error AFTER watching it extrude a fair amount of filament. Though this test also brought something to my attention, the bowden tube that connects to the nozzle flexed like it was gaining tension

then snapped back into place after a brief moment and I have never seen it do that till the recent Issue. I’m not sure where to go with this problem and I am afraid of the worst right now.

Have you opened up the extruder gear also?

I had some cases where a small piece of filament was curled up just below the gear and above the nozzle pipe.

It gives the same error/behavior you described.

Have you checked the cutter? It may be jammed.

the gear’s are clear and functioning fine, as I mentioned its feeding filament and extruding completely fine, it goes through the pre print feeding where it cycles the filament through to clear out the last bit used but once it finishes that is when it throws the clog error

the clipper was both clean, sharp and clear in its pathway when i followed the guide to check it

Do you use thermal grease when swap?

Yeah, I used the paste provided when swapping the nozzle

20 days later and I have tried going through each part and the issue persists… I was really hoping someone would have the solution but its looking to me this problem might need the use of a warrenty

Could be that the temperature is too low for the filament to melt properly. I was having that problem with mine, and swapped out the extruder main board, and the nozzle/heater/temperature sensor unit, and that seemed to help. Of course, I also made another change at the same time that may have contributed, as I was also getting problems with blobs of molten PETG constantly clogging up the cold parts of the extruder. To fix that issue, I changed my PETG settings dramatically:

Speed of the first cooling move: 2.2 → 20

Speed of the last cooling move: 3.4 → 10

Number of cooling moves: 4 → 6

Between those two changes, all of the clogging problems went away, and I made all of those changes at about the same time, so I can’t say for sure which changes were actually responsible for fixing the issue.

BTW, if you haven’t already shoved the nozzle cleaning needle down through the nozzle to press out any gunk, that’s worth trying. If it won’t go in when the nozzle is supposedly at temperature, you definitely have a hardware issue.