So let’s taco bout it. Ever wondered what 56 microns looks like? It’s about:

• 1/40th of a Pringle’s thickness

• 8 red blood cells stacked together

• Half the thickness of a human hair

• Just slightly thicker than a bacterium

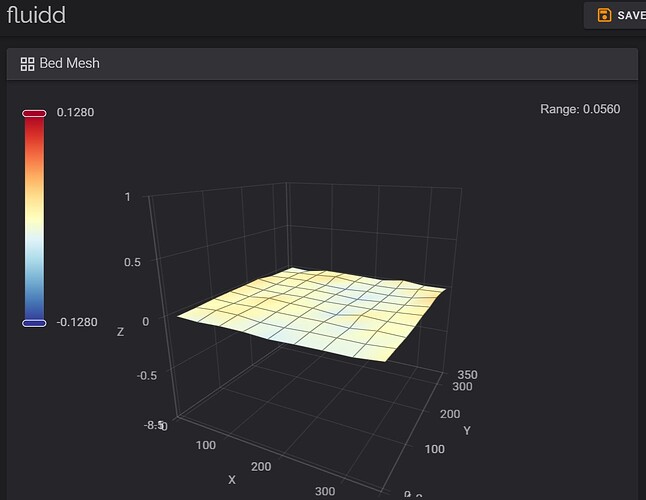

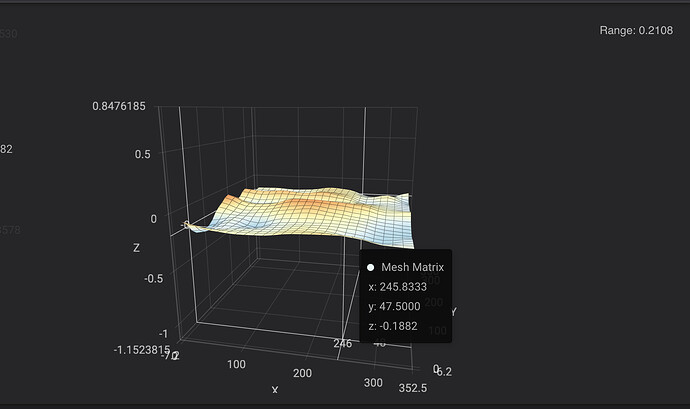

That’s the bed mesh deviation I managed to achieve on one of my Creality K2 Plus units after hours of heat soaking at 60°C—on a smooth PEI plate. On the standard textured PEI plate, I got it down to 67 microns (.067 mm), which is still ridiculously tight. What did I start with??? .89mm

How did I do it?

A combination of:

![]() Stretched aluminum tape (precision layering at its finest)

Stretched aluminum tape (precision layering at its finest)

![]()

Stolen Borrowed and quickly returned my wife’s Kapton Tape she uses for vinyl prints ![]()

![]() A sacrificial offering of burnt fingertips to Cuva and the FDM gods

A sacrificial offering of burnt fingertips to Cuva and the FDM gods

![]() A ridiculous amount of patience

A ridiculous amount of patience

![]() A hairnet, and banishing my dog from my office… Yeah, a single dog hair can throw it off at this level!

A hairnet, and banishing my dog from my office… Yeah, a single dog hair can throw it off at this level!

This wasn’t just a one-off experiment. I’m currently working on a repeatable method and guide to help others dial in their bed to .25mm deviation or better, because let’s be real… getting that first layer perfect every time is a game-changer!

This is why I’ve been a little MIA the last few days, but trust me, it’s worth it. Stay tuned, I’ll be dropping a guide soon to help others push their K2 Plus (or any FDM printer) to the next level.

Let me know!!! Is this something any of you would like to see!? How dialed in is your bed, and what’s the wildest trick you’ve used to get it there?