Look like pressure advance need to be tuned.

That looks like either wet filaments, or using a lot of slicer settings that are not working as expected..

Suggest

a) drying filament again, even if it came out of a new box in case it wasnt sealed properly

b) uploading your 3mf

c) give details of what you have tried & setup.., I.e. any printer mods, what filament type, are you using non-standard density/max volumetric flow rates, or using non- creality filament with a CR profile etc.. changed nozzle size, but not profile etc..

I have tried to dry the filament as well with no success. I am using generic PLA. I actually increased my wipe distance and manually tuned the PA. The first print seems a little better, stay tuned guys, I’ll let you know how I make out with it. THANKS.

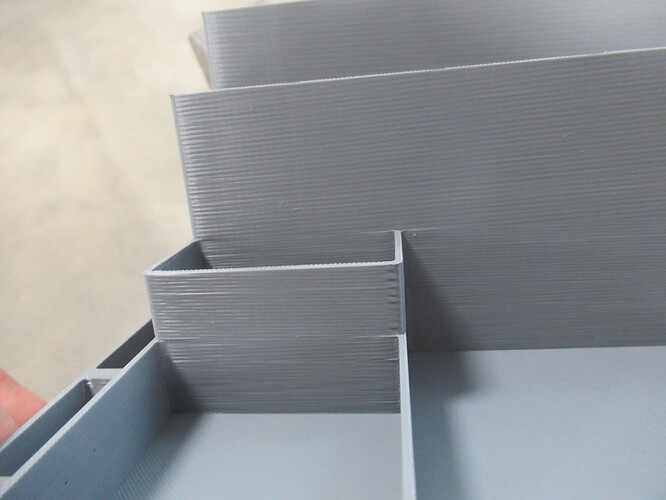

This is a print after changing PA setting, Looks a lot better. I’m new to this so just wondering, if you have the printer do a PA cali, shouldn’t that be all you have to do to fix this issue? What I noticed was when I told it to run PA Cal it printed nice for one print and then the second was back to where it was before. Any comments….?

PA and Flow Calibration values are not saved..you need to view those values in fluidd (printer ip port 4408) and take those values, save them as a user filament profile in CR (or whatever slicer you are using)

Edit the system filament profile you used (Cr,generic etc) and save a “user” version of that with the new values..

Then use that filament profile for that brand

Thank You!

Yeah, your PA is set incorrectly. Thats it, thats all