Jack,

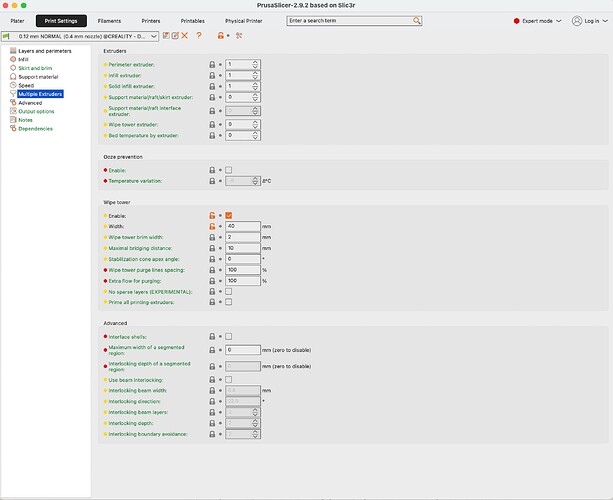

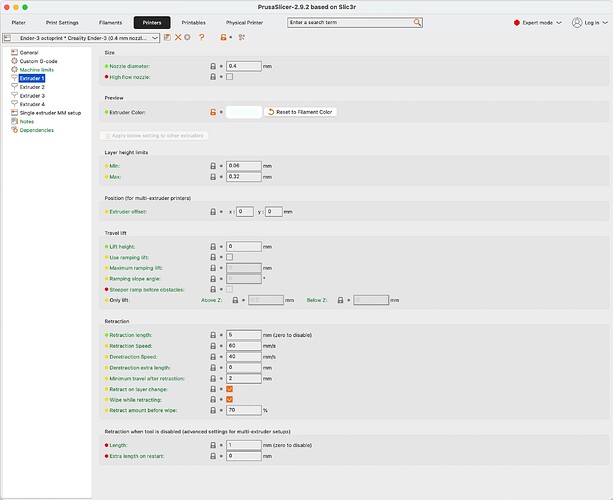

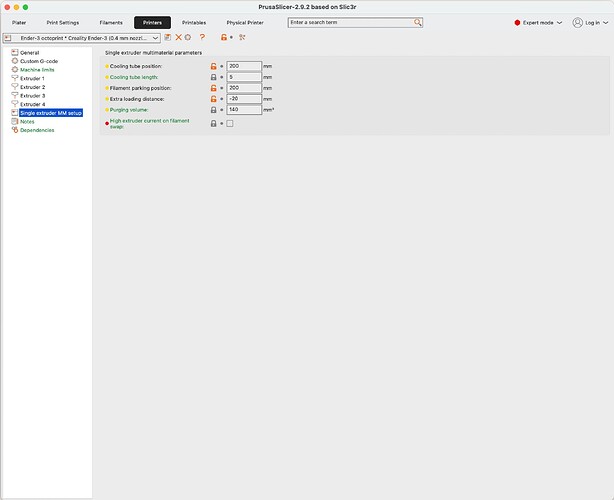

Here is my PrusaSlicer config:

From the PrusaSlicer config, few snapshots that might be interesting:

Custom G-code in “Printers” settings:

Start G-code:

G90 ; use absolute coordinates

M83 ; extruder relative mode

M104 S{is_nil(idle_temperature[0]) ? 150 : idle_temperature[0]} ; set temporary nozzle temp to prevent oozing during homing

M140 S{first_layer_bed_temperature[0]} ; set final bed temp

G4 S30 ; allow partial nozzle warmup

G28 ; home all axis

G1 Z50 F240

G1 X2.0 Y10 F3000

M104 S{first_layer_temperature[0]} ; set final nozzle temp

M190 S{first_layer_bed_temperature[0]} ; wait for bed temp to stabilize

M109 S{first_layer_temperature[0]} ; wait for nozzle temp to stabilize

G1 Z0.28 F240

G92 E0

{if total_toolchanges == 0} ;; This happens when printing from T0 with only 1 color

{if initial_tool == 0 }

M83 ; but make sure the extruder stays in relative

G1 F300 Z3.16 ; move up a millimeter to get out of the way

G1 F9000 X0 Y0

G1 F300 Z15 ; too close to bed--move to at least 15mm

; Push filament to tip

G0 E200 F1000

G92 E0

G0 E200 F300

G92 E0

M400 ; Wait for previously to be done.

G1 F9000 X2 Y0

G1 F300 Z0.2

G1 X2.0 Y200 E10 F1500 ; prime the nozzle

G1 X2.3 Y200 F5000

G92 E0

G1 X2.3 Y10 E10 F1200 ; prime the nozzle

G92 E0

{endif}

{endif}

End G-code

{if max_layer_z < max_print_height}G1 Z{z_offset+min(max_layer_z+2, max_print_height)} F600 ; Move print head up{endif}

G1 X5 Y{print_bed_max[1]*0.85} F{travel_speed*60} ; present print

{if max_layer_z < max_print_height-10}G1 Z{z_offset+min(max_layer_z+70, max_print_height-10)} F600 ; Move print head further up{endif}

{if max_layer_z < max_print_height*0.6}G1 Z{max_print_height*0.6} F600 ; Move print head further up{endif}

{if total_toolchanges == 0} ;; This happens when printing from T0 with only 1 color

M83 ; but make sure the extruder stays in relative

; Push filament to tip

G0 E-100 F300

G92 E0

G0 E-300 F1000

G92 E0

M400 ; Wait for previously to be done.

{endif}

M140 S0 ; turn off heatbed

M104 S0 ; turn off temperature

M107 ; turn off fan

M84 X Y E ; disable motors

Tool Change G-code

;begin switch from extruder {previous_extruder} to extruder #{next_extruder}

M117 Unloading Tool T[previous_extruder]

M83 ; turn relative distances for the extruder

; unload extruder {previous_extruder}

G92 E0

;;;G91 ; move to relative mode

M83

; load extruder #{next_extruder}

M117 Loading Tool T{next_extruder}

;{endif}

M400 ; Wait for previously to be done.

; Select the correct material

M117 Loading Tool T[next_extruder]

; Disable extruder

M84 E

M400 ; Wait for previously to be done.

{if next_extruder==0}

OCTO1

{endif}

{if next_extruder==1}

OCTO2

{endif}

{if next_extruder==2}

OCTO3

{endif}

{if next_extruder==3}

OCTO4

{endif}

G4 P1000 ; Pause for 1000 milliseconds (1 second)

M400 ; Wait for previously to be done.

; Enable extruder

M17 E

M83 ; but make sure the extruder stays in relative

{if previous_extruder<0}

G1 F300 Z3.16 ; move up a millimeter to get out of the way

G1 F9000 X0 Y0

G1 F300 Z15 ; too close to bed--move to at least 15mm

; Push filament to tip

G0 E200 F1000

G92 E0

G0 E200 F300

G92 E0

M400 ; Wait for previously to be done.

G1 F9000 X2 Y0

G1 F300 Z0.2

G1 X2.0 Y200 E10 F1500 ; prime the nozzle

G1 X2.3 Y200 F5000

G92 E0

G1 X2.3 Y10 E10 F1200 ; prime the nozzle

G92 E0

{endif}

G92 E0

M83 ; turn relative distances for the extruder

M117 Tool T{next_extruder} In use

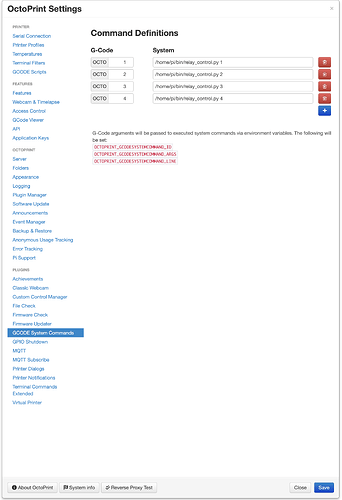

Regarding Octoprint config, here is a snapshot of the plugin I use for custom G-codes:

And here the content of the “relay_control.py” script for 3 relays as described before assuming “HIGH” is configured to OFF on the relays and “LOW” is ON:

#!/usr/bin/env python3

import RPi.GPIO as GPIO

import sys

import time

# Pin definitions

RELAY_PINS = [2, 3, 4] # GPIO numbers

MAIN_RELAY = 2 # GPIO number

RELAY1 = 4 # GPIO number

RELAY2 = 3 # GPIO number

# Ensure a valid argument is provided

if len(sys.argv) != 2 or sys.argv[1] not in ["1", "2", "3", "4"]:

print("Usage: python3 relay_control.py <1|2|3|4>")

sys.exit(1)

# Setup GPIO

GPIO.setmode(GPIO.BCM)

GPIO.setup(RELAY_PINS, GPIO.OUT)

# Main

if sys.argv[1] == "1":

### everything off for 1

GPIO.output(MAIN_RELAY, GPIO.HIGH)

GPIO.output(RELAY1, GPIO.HIGH)

GPIO.output(RELAY2, GPIO.HIGH)

elif sys.argv[1] == "2":

### only RELAY1 for 2

GPIO.output(MAIN_RELAY, GPIO.HIGH)

GPIO.output(RELAY1, GPIO.LOW)

GPIO.output(RELAY2, GPIO.HIGH)

elif sys.argv[1] == "3":

### MAIN ON for 3

GPIO.output(MAIN_RELAY, GPIO.LOW)

GPIO.output(RELAY1, GPIO.HIGH)

GPIO.output(RELAY2, GPIO.HIGH)

elif sys.argv[1] == "4":

### MAIN ON for 3

GPIO.output(MAIN_RELAY, GPIO.LOW)

GPIO.output(RELAY1, GPIO.HIGH)

time.sleep(0.3) ## this is to give a break to the power supply

GPIO.output(RELAY2, GPIO.LOW)