I am struggling to get the extruder to feed tpu filament without jamming in my new e3+ v3. It kinks and stops extruding. I have stopped using the pfte tube, moved the feed to top loading with zero friction , reduced retraction and speed but still the extruder jams after multiple attempts. Other filaments print absolutely perfect and fast. Any tips as I don’t think others have this issue with the new V3 or the K1 series extruders. I actually was more successful printing with much tweaking with my OG E3 from years ago. Is there a way to reduce the tension on the new sprite extruder?

I’m having the exact same issue. I printed a temp tower with tpu and it failed on the last temp, which is fair given it was probably too low. But it now refuses to print tpu even though everything else prints fine. It doesn’t get clogged or stuck… it wont go through and just clicks. I’m thinking maybe the gears are too tight for it? idk

Printing TPU on all of my printers I keep the retraction distance down to 0.8-1.0mm. Temperature tower is critical if you want to avoid stringing. For me 230°C is correct, 5°C above or below and it will string. It is more tricky than PETG but not super difficult. Currently running TPU through a 0.2mm nozzle with no clogs, bit more stringing than 0.4mm but its not bad.

A bit late to the party, but I have 2, Ender 3 V3 Plus printers.

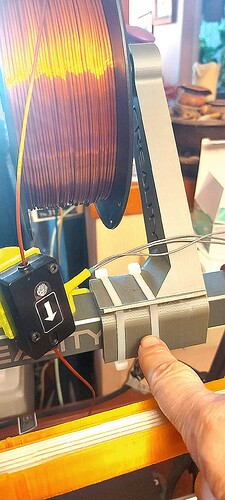

I’ve only printed TPU on one and on that one, I mount the spool on the top rail and I moved the runout sensor to just under it.

I don’t use the long PTFE tube. Rather, I cut a 4" (ish) piece that goes into the top of the extruder.

With this setup, it reduces most of the drag that having the spool on the side and going through the longer tube causes.

So far, TPU has printed just fine.

I also use about 230C, SLOW, but I didn’t yet play with retraction.

I’ll do that the next time I print TPU.

I have a 12" loop of capricorn tubing on top of my printer, doesn’t seem to be significant drag one like this

I am still struggling, retraction down to 0.3, slowed speed and temp tower done but my 3 plus v3 gets stalled as the filament feed still stops due to feed failure. Spool is mounted above with no pfte tube at all, direct into the extrudeerMy upgraded OG ender 3 works better than my new upgrade. Frustrating and have even reduced tension to avoid stretching/thinning the filament. Any tips or ideas as to how to get this to print tpu would be really appreciated.

![]()

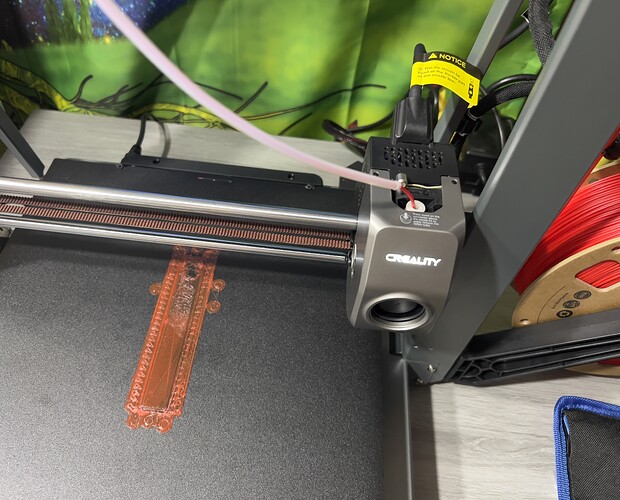

Same. I actually bought a second one. Luckily this one doesn’t have that awful noise the first one does. I’ll probably exchange that one. But the same issue occurs with the new one, the extruder gets stuck and won’t print tpu and it just clogs up everything. Here’s the new printer and when it got clogged. First one is just showing how I have it set up.

I’ve gone one step further, eliminated the pfte tube and direct feed from the top to try to resolve the TPU issues (possible stretching leading to extruder fail) but still can’t get the print to keep feeding for a print. THis printer was a major upgrade in every way from the OG E-3 but this is the only struggle I am having. Not sure how I can adjust the extruder tension in my research anywhere.

Thanks for the suggestion of adding the short PTFE tube for TPU, it stopped the clicking and jamming right away.

I’m interested where you added this short length. I’m willing to give it a try so I can at least try to print tpu on my new model.

I’m glad that worked out.

One question, did you mount the spool on top or “above” the top rail somehow?

If you did and if you printed out that top-rail spool holder that is on the USB (or on the machine’s folder), I have to also suggest that you add one or two of those plastic

Zip Ties.

Wrap it/them around the plastic part that clamps onto the top rail so that it keeps the plastic “C” shape from opening up and letting the spool fall.

BEEN THERE, DONE THAT!

The spool holder let loose and it all fell. I was lucky that nothing got damaged.

Hope that helps.

Mine is already mounted above to try to keep friction and tension to the minimum but still having feed issues where it grinds up the tpu and stops feeding mid print

I added the short PTFE tube at the extruder feed (because I top mounted the spool), the tube must either align the TPU as it enters the gearing in the nozzle, or keep the TPU from bending in there somehow. I’ve done many TPU prints with this tube, and all have been perfect, without the tube about 75% of TPU failed from jamming. I don’t use the tube with PLA or PTEG.

Thanks for the tip, at this stage I’m willing to try anything. So far it’s the one thing this printer struggles with, everything else is amazing

Thank you so much. I completed my first tpu print finally with your tip. Looking forward to many successful prints in the future. What made you think to try this?

I’m not sure who you are asking there as I mentioned the 4" PTFE tube, directly into the extruder only, on 13Feb. LOL

I’m glad that you got it going. What I found too, is that there as to be as little drag as possible.

I have some very soft TPU that I haven’t tested with as yet, but I think that when I do, I’ll bypass the useless filament runout sensor and move the spool to this spool stand that has smooth bearings. The spools spin easily with much less drag than just on the top-rail spool holder.

Mine will often buckle right after the drive and the gears just start spinning on it.

I just noticed it clicking but let it run until I could tell it failed to print a layer so I just paused it, released the drive gears, pulled the filament out and cut off the damaged bit.

Then I just shoved it back in, pushed it in a little more until it started coming out the nozzle, locked the gears around the filament and hit resume. Amazingly, it was able to recover printing even after having missed a layer. I was printing cable ties so I didn’t care if it looked kinda bad. I don’t think I would’ve had the same luck if it was printing infills though.

The ONLY successful thing I was able to do was buy a diamondback nozzle and upgrade to microswiss flowtech hotend… after that, TPU has had no issues…

Until today where I tried to (after printing a tpu model for 3+ hours a couple weeks ago) was unable to print and did the usual slip and click. I’m currently doing some testing to see what’s going on… funny thing is, after failing to print multiple times, I am printing the same g-code from the successful print with different color filament (all other settings/brands are the same - although I did add the PFTE tube after the failed prints (after reading the comments on here)…. so far, its printing beautifully. I didn’t clean or change anything… so… I will try to hone in on whats happening. but it does seem like the tpu is somehow getting “bunched” up and im not sure why or what settings could be causing it… i’ll update on what i can find