Hi Vad_Che

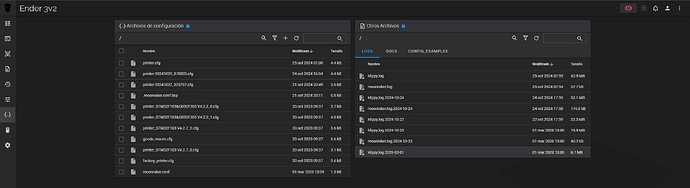

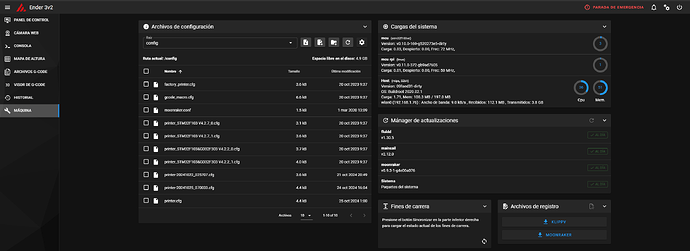

I am using fluidd to manage my printer but choose your own.

A1:

You have right.

Nebula pad with root brings you full control above everything around hardware control so yes printer.cfg is the key. AND with this comes BIG responsibility. Think twice before you will make any adjustment, check klipper documentation etc… whatewer you do is at your own risk.

During 1st startup skip wizard with calibration. Otherwise you will hit bed with nozzle.

Step 1 - Adjust cr touch XY vs. nozzle offset in bl_touch section. In mine case with kit fan mount plate values are X 41 and Y 31 for an example.

Do you own measuring 1st on all steps.

Check safe bed home coords and set values to center of bed. For start XY values around 100 are enough. With 0 you vill hit bed.

After save and restart homing procedure will start to work safely.

Step 2 - perform Z offset calibration

Check value in printer.cfg and set it to 0.0

Nebula Pad menu offer you good interface for it. Fluidd has this possibility too with smaller microsteps.

Step 3 adjust bed size within XYZ axis sections

Here you will need to be careful to not go so far with values. Expect lot of save and restarts. Check mechanical limits, and perform fine tune by units of milimeters Otherwise XY motors and belts will suffer… try to minimize it as much as possible.

In my case i am using minus values for XY starting position because end stop with 0 and Sprite geometry are outside of bed.

Be careful with X axis and top screw on carrier. I shortened mine to be able go far begind right plate. Thanks to this I have got full 220x220 range.

If you are ok with max of 205 mm on X keep it as it is. Or you can do this anytime later.

Step 4 bed mesh coords

Same as for step 3. You can reach area outside of mechanical stop.

Count with bl touch coords and take these into your calculations.

Tip: Set corner coords to bed knob screwes if your printer have these.

Slow down velocity on z axis to slow down Z axis approach while cr touch is performing bed mesh calibration for better accurate results.

Step 5 Fine tune of safe bed home

According to the new geometry from step 3 take into count with bl touch coords adjust real center of bed.

Step 6 perform manual bed level with paper

You can do it from Nebula Pad interface or from fluidd

Step 7 extruder E motor calibration

Standard test with extrude of 100mm filament and caliper measurment. According to results modify E step section value.

After these steps your printer should be calibrated from mechanical side.

I recommend you to perform thse calibration prints:

- Flow cube to measure over/under extrusion I have to set 0,94 in slicer for PLA and PETG wit 0,4mm nozzle.

- Pressure advance tower - stock value 0,44 works well for me but if you want to have max precision you have to perform it for each spool.

Prepare your macros in separate file an create include for this file in printer.cfg

Start with START PRINT macro. Follow klipper documentation how to prepare this file and how to intergrate it with slicer. Then END print…

Nebula Pad has own macros but i do not like the start macro whrere nozzle is preheated with Z at 0… etc…

A2

I’ve bought kit where short cr touch ribbon cable was included. In case that you do not have it use the long one delivered with CR touch.

Good luck, hope that you will find out this reply as useful for you.