I’m at my witts end here. I’ve done calibration tests out the wazoo, reset everything back to zero state, changed to a unicorn nozzle, replaced the extruder, checked every single screw, checked the gantry to be level, played with the z offset, and I’m just about done with this. I’ve even tried the thin bowden tube that comes with the ceramic upgraded hot end and purchased and cut a normal bowden tube also.

But for some reason I am constantly getting jams between the extruder and the hot end. I’ve played with temperatures from 200 to 230 and ran temp tests. But just can’t get prints to complete..

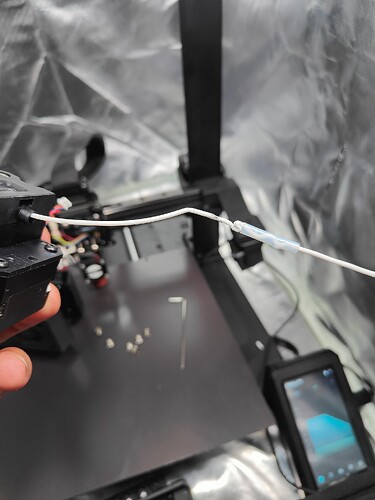

Here’s the picture of the latest jam in any help or ideas would be desperately accepted