Hi all. Total newbie here. I bought a original Ender 3, the first few PLA prints worked great. I switched to PETG and was able to successfully print two sets of camera housings using Prusa Slicer. But started experiencing clogging in the bowden tube at the hotend. So I upgraded to a Spider V3 Pro hotend and haven’t been able to successfully print ANYTHING taking more then 20 minutes to complete, due to jamming in the Spider HEATBREAK. I have tried every setting I could find online to stop heatcreep, with absolutely no change in ability to print beyond 20 minutes before jamming in the heatbreak.

I switched to Cure Slicer in an attempt to reduce the number of retractions, but still no success except print time increased to 30 minutes before jamming in the HEATBREAK again. I upgraded the extrudor and E-Stepper motor. I upgraded to a Capricorn bowden tube. I calibrated the E-Steps, I managed to run a .8mm flow cube test (Perfect, it only took 10 minutes). I also replaced the hotend cooling fan (soon to upgrade to a better cool fan system ONCE I CAN PRINT SOMETHING)

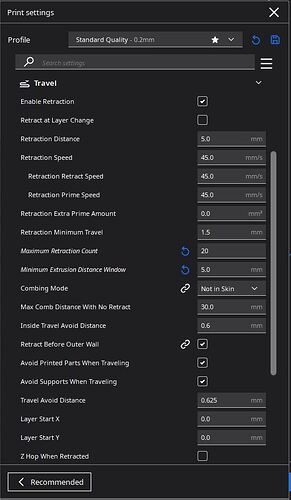

I would print a better fan shroud IF I COULD JUST PRINT SOMETHING. I’m at a total loss. Could somebody please help? Here are some Cura TRAVEL settings that some handlebar mustache clad fellow/Guru from Cura YouTube tutorial who suggested to try. I would imagine using Crealities own Ender 3 settings for PETG would at lease be productive once in awhile. This thing should not be having this issue with their suggested settings I have tried, unless Gremlins are real.

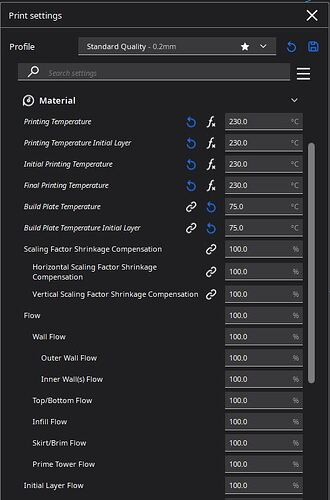

I have tried PETG settings:

Filaments: Overture PETG black, SUNLU PETG black, ESUN PETG blue

Print temps: from 250c to 220c (230c seems to be the best for my Emder 3)

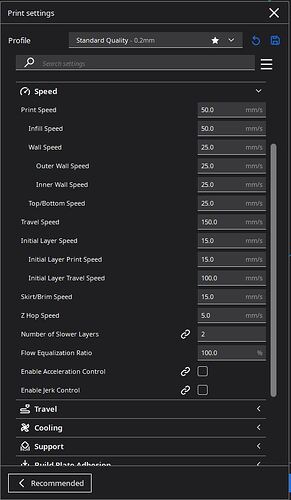

Print Speeds: 35mm/s to 80mm/s (50mm/s look best)

Extraction lengths: from 6mm to 1mm (5mm no stringing)

Extraction Speeds: 40mm/s to 80mm/s

Travel Settings per images below.

P.S.:

What is the white plastic sleeve for on the Spider V3 Pro heat break? Will it help cool the heat break if I remove it?