I’ve had my Ender 3 for two months now and I’m having issues with the extruder; the filament keeps slipping and there’s a clack clack sound. I’ve checked the gear, but it doesn’t seem damaged, and I’ve looked for any jams, but found nothing. Tightening the extruder clamp makes the situation worse. What should I do?

Hello @Sergio_Ruiz

Welcome to the Creality Forum ![]()

Have you been able to manually push filament through the extruder..?

Is the filament binding somewhere so the extruder can’t pull it…?

Now that you mention it, I also can’t push it. If the filament is too damp, can it clog?

That clicking noise is most likely the extruder gears slipping trying to push the filament through. Probably a piece of fiment is blocking the nozzle or gears. I’m thinking you might have to take the extruder apart and look for something blocking it…

Damp filament can still go through the extruder but it will be a mess and the quality of the print will be pretty bad depending how wet it is…

I took it apart four times yesterday, but I didn’t find anything. The printer is two months old.

You loosen the extruder clamp and still can’t push the filament through with the nozzle heated up…?

I don’t remember well; right now, I’m drying the filament with an improvised dryer to rule out if it’s the filament.

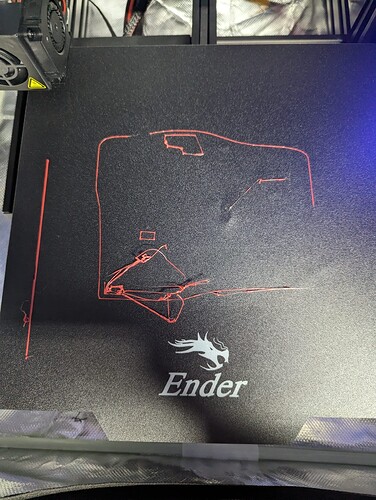

Now the extruder isn’t making a clicking sound, but I’m having flow issues. Here´s a photo.

I’m using a 0.8mm nozzle.

Any solutions?

So what changed to make the extruder work now…?

You will need to change your profile to accommodate an 0.8 nozzle instead of the default 0.4 nozzle. If you didn’t that would cause flow to be wrong…

Make sure that bed is level… It looks a little rough…?

Maybe the extruder problem still gives me trouble. It used to make that clicking sound after about 15-20 minutes of printing. I changed the nozzle size from 0.4 to 0.8, and I also adjusted the bed. I’m going to try using Cura to see if it works better because I’m running out of ideas.

Also i´ve been drying the filament for 4 hours at 50ºC

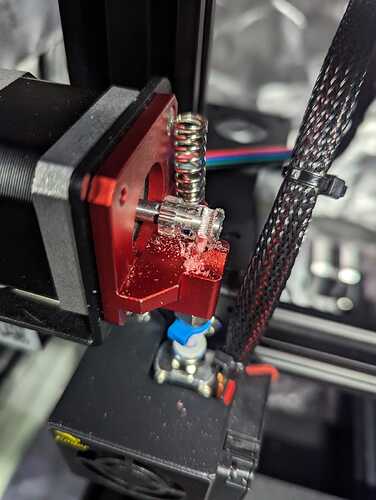

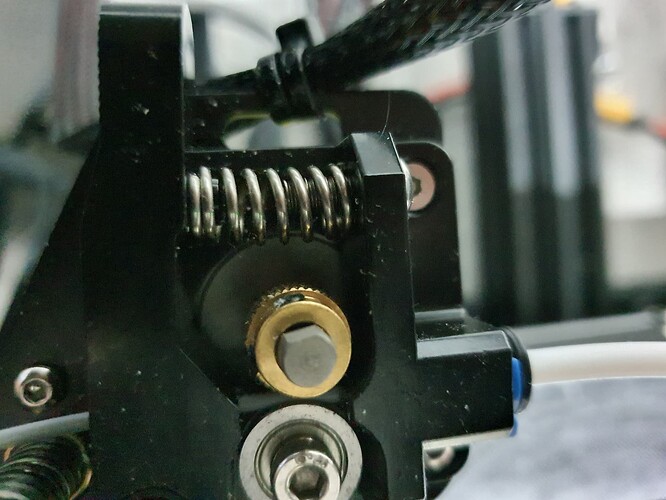

Update: I installed the direct extrusion upgrade on my Ender 3 to see if it would improve, and I raised the nozzle temperature from 200 to 215 degrees. It seemed to be getting better, but this morning I found it like this: (attached photo)

There’s a separate piece; I’m the one who separated it, and I also disassembled the extruder to show the filament.

looks and sounds like your extruder is gripping the filament too tightly, then as it performs retractions the filament starts slipping and you hear the clicking as it tries to push the filament through.

take out your filament does it have teeth marks where its been through the extruder?

try removing the metal sleeve under the extruder spring, this will reduce pressure on the filament, ive done this on all my enders, never heard the clicking since.

I think the extruder makes a clack clack noise because the extruder gets clogged. How can I ventilate the top part of the extruder more so it doesn’t get clogged?

Final update: The Teflon tube was too far from the nozzle, causing a blockage. Removing the blockage solved the issue.