I found tiny metal bits from the clamp blocking the filament cutter blade fully cutting the filament. i cannot get a hold of the support people nor get a replacement. Printer is down until this part is available sometime in March. Fxck!

I guess I can try a tiny amount of super glue gel on the boden tube.???

you could try some glue just to get through printing this fix

Print that and use it until you can get a proper replacement

"I had to design a solution due to K2 plus extruder (what I believe ) design flaw. "

Nice! The site wants me to buy the design, which I don’t care, that’s fine for me. It’s 50 somethings (I have never used that site before). I have lots of points on Printables.com. I’ll figure it out. What is the hardware piece that fits your print? I will get that ordered right away if I don’t already have one.

Okay, I have the proper mm boden thingies ordered from Amazon and ABS Black ordered.

Note: I have never printed ABS on my Bambu X1C before (the printer the part will need printed on). I have been afraid of it since I always heard it is toxic. The printer is in a room that can not be ventilated this time of year, and I do not have the carbon filters for my X1C yet.

The ESUN ABS will arrive Wednesday and a spool of Creality ABS, which claims it is not toxic (??? Just fancier PTEG???) will arrive Thursday. I am also going to look for carbon filters for my X1C.

Thanks again for this fix which is probably better than the original design!!!

my bad man didnt realize they were charging for that one

Here it is for free

https://makerworld.com/en/models/1005171?from=search#profileId-989166

I havent had to use this yet as Creality sent me a replacement before this file was available but I will probably print a couple to have on hand just in case

Okay, I have the proper mm boden thingies ordered from Amazon and ABS Black ordered.

Note: I have never printed ABS on my Bambu X1C before (the printer the part will need printed on). I have been afraid of it since I always heard it is toxic. The printer is in a room that can not be ventilated this time of year, and I do not have the carbon filters for my X1C yet.

P.S. - Yes the original filter is carbon, but it has never been replaced. New one on order and signed up for a subscription on Amazon.

The ESUN ABS will arrive Wednesday and a spool of Creality ABS, which claims it is not toxic (??? Just fancier PTEG???) will arrive Thursday. I am also going to look for carbon filters for my X1C.

For now, I am printing one in PTEG to try.

Thanks again for this fix which is probably better than the original design!!!

Sir, Rob, you are a freaking genius! You should get more than 50 cents for this!

I found 6mm Boden fitting in my old Ender 3 collection. I also am lucky enough to have a box 3mm screw assortment from Aliexpress.

I printed, it for now, in PTEG, while I wait for the PVC Filament to show up.

Right now, the printer is printing again.

I tested also another model which you can find here: https://makerworld.com/de/models/1020734

Attention: If you install any of the above adoptions you need to re-run input shaping (best all calibration)!

"I tested also another model which you can find here: https://makerworld.com/de/models/1020734

Attention: If you install any of the above adoptions you need to re-run input shaping (best all calibration)!"

Thank you. That design looks a little more beefier maybe. It is they way it should have been day one. Brilliant.

Yes on the recalibration.

I am still having the filament cutting issue. I’ll double check that I have the cutter in in upright and the post it pushes against (although I do not think it is broken, but at one point, after the firmware update, it started having servo control issues and slammed the print head fast and hard in to the left side of chamber). To me, it seems the cutter is not sharp at all. I have a bunch on order from Creality and Aliexpress. Those will take several weeks to get here I imagine.

Just printed it in PVC on the X1C. Turned out great, especially with the 10mm hole this time allowing for the tube to feed right through - cool. You were right, that PVC part it strong.

Holy crap that extrusion test the X1C does it damn hard to get off the textured PEI plate!! I am still working on that - lol

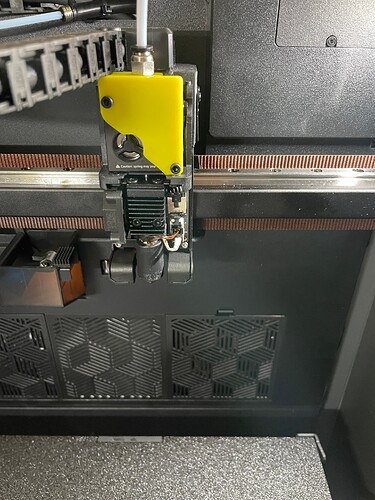

Printed in PVC, really strong and hold 10mm connector great. One issue, the Creality head cover won’t fit over this one (too high). That is no big loss though, it works great.

Thank you for the links and information, same issue happened to me today, the 8th day I’ve had the printer. I did find two teeth inside the extruder and two in the cutter on the magnet. And I think one more fell out when I took the extruder apart. As soon as I can confirm that Creality is going to send me a replacement part, I’ll glue the tubing in and print the part in ABS. Already have the PC4-M10 fittings coming. Kinda stinks, I was hoping to finish printing the tiles for my Multiboard wall tomorrow.

Are they sending one? I emailed them a few weeks ago about mine being broken and they never responded to me. I have some on order from Aliexpress, but they can’t ship until March sometime (guess it will get hits with more tariffs now).

They’re currently closed for the holiday until at least tomorrow. I used Loctite plastic bond to glue the tubing back into the fitting. Let it sit for 24 hours, then printed several versions of the extruder covers in ABS but the glue is holding for now so I’ll put one of them on if/when it fails. I’ll update here if they do actually send me the cover, but after picking metal teeth out of my extruder, I don’t really want to put another one in there, for fear of it permanently damaging something next time the cheap connector fails.

Just an update, got an email requesting my address (again) so they could ship me the extruder cover. The Loctite Plastic Bond is still holding up under more or less constant use.

I got an email from them yesterday also, no ideal for which complaint - lol. They didn’t say, just wanted my shipping address and what not.

This solution worked great. I only found a single tooth on my cutter magnet. I inspected everything else as well as I could, removing borked bits of filament and cleaned everything.

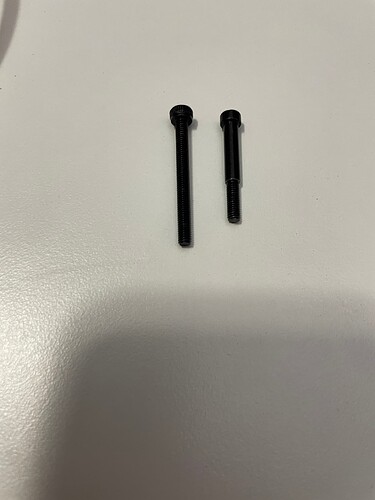

The screw on the left is the new M3-30 screw and the screw on the right is one of the original screws. All three of the original screws are different lengths, but you can use the M3-30 for the longer screws, and just use the short screw (you’ll see what I mean when you remove the extruder cover). I was concerned that the new screws would bottom out, but they didn’t and seemed to fit snugly.

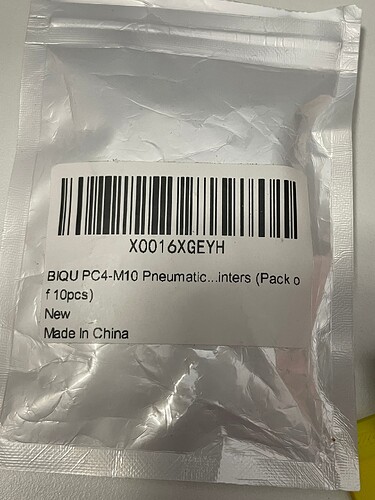

Here are the couplers I used. I picked up a 10 pack from Amazon for about $8.

The new coupler fits perfectly. It threads in tightly but with some pliers and a slight effort, it’ll thread all the way down.

When fitting the new adapter over the extruder cover, make sure to seat the standoffs into the original screw setback holes. Also when attaching the entire assembly back onto the extruder head, double check that everything is properly seated.

When inserting the bowden tube into the new coupler, I made sure to slide it all the way down as far as possible into and past the original (broken) coupler. This amounted to about 40-45mm or perhaps even more and allows the filament to bypass all this mess when printing.

Final assembly involves threading in the M3-30 screws, and the third screw on the side.

I was concerned about this doing this at first, but after printing with it, I’m sure this is as solid a solution as any other. This keeps my printer working until the replacements arrive.

Thanks everyone!

Well the replacement extruder cover they sent me just broke the same way as the 1st

The 1st one lasted about 2 weeks, this one lasted about 4 weeks

I dont print alot either, my printer is only used for personal stuff, mostly printing toys and stuff for my daughter

I hope they are working on a suitable replacement for this obviously flawed design, i am not going to be happy if i have to buy a new extruder cover every month

So since i have 2 broken extruder covers i decided to try and see if i could remove the broken connector from one of them , I use some needle nose pliers and was able to pull it right out

I happened to have the K2 plus connector kit that i ordered and noticed that the connectors in that kit are the same as the connector i pullled out of the extruder cover

https://store.creality.com/collections/accessories/products/k2-plus-connector-kit?spm=..collection_cc8cf8b4-3da1-49c7-bc32-dd0e246caef8.collection_custom_1.6&spm_prev=..index.header_1.1

I was able to press in a new connector into the extruder cover and its been printing just fine

Now i just need to see if i can find some higher quality press fit connectors to use as replacements as im sure the ones in the connector kit are the same as the garbage ones in the extruder cover