I’ve had my Falcon 2 22W for about 3 month and lately while trying to cut a 20 mm wood board I set the settings a bit too low on speed and the wheel at the bottom of the railing module started to catch fire but fortunately I managed to kill the fire before it ruined the laser or the rest of the device.

I couldn’t find where to buy the exact replacement wheel but found a similar one on Amazon and managed to fix it and have a smooth non wobbling movement of the laser module on the horizontal railing.

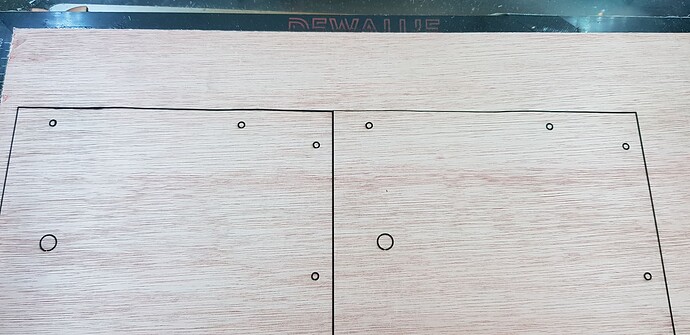

However I get non perfectly straight cuts on the horizontal axis only (the vertical axis lines seems perfectly straight ), as shown on the pictures

Anyone know if it could have something to do with the wheel not being genuine? or could it come from the belt that carries the module left to right that was very slightly burnt but seems to still have the same original tension?

Assuming all wheels have been visually and physicaly inspected and are in good shape, with no bumps, fully round, …

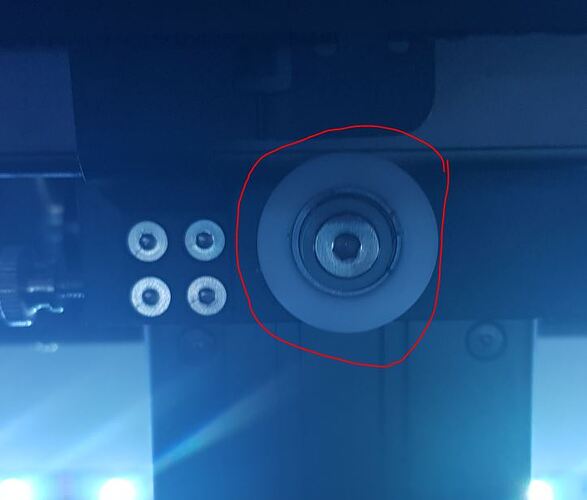

With that out of the way, check the concentric nut that sits behind the laser unit to make sure it’s not too tight or too loose.

It could also be the belt for the left-right movement that might be too loose, but I doubt that as you’d get other weirdnesses.

When the carriage goes left-right, putting your fingers/hands on both sides, do you “feel” it moving or wobbling? Note that it might be hard to feel as the movement seems pretty small. You might try with slow and fast movement to feel it better.