I am not a professional. Far from it actually but…

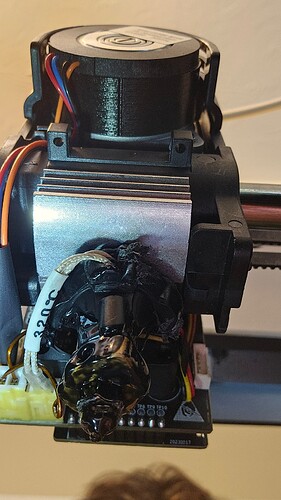

- remove the hotend

- boil it or just heat it to remove the excess blobbing

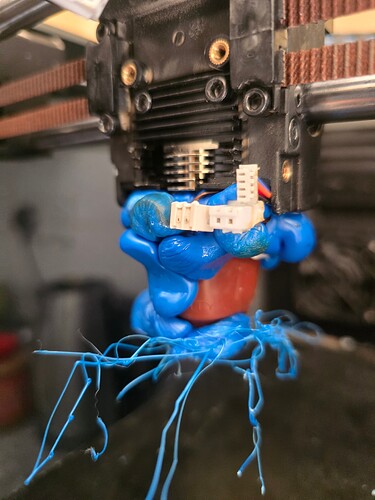

- I see a lot of people in the 3D Printing world get blobs at times

Although, I do not think this is a Creality concern, I may just be wrong. I had some issues at first before updating/upgrading (OTA stuff) and some issues of my own with not allowing the heated bed to become cool before trying to handle it and remove the print.

But yea…

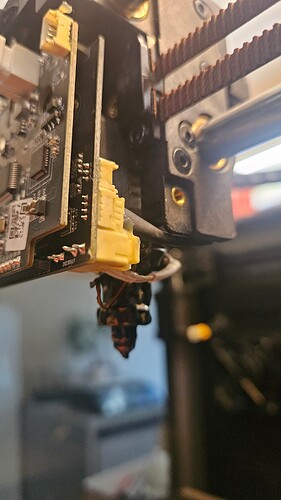

The boards should not get hard-to-remove PLA or PETG or whatever filament you are using on them. That would be sort of a pain to get cleaned up and removed properly.

But yea…I do not think Creality with their branding and pure, excited nature in the industry would consider this a warranty thing. So, heads up.

Steam works too. If you have a steamer with a jet stream, remove the nozzle and clean it off and/or heat the nozzle in the GUI on the machine LCD to remove extra-stubborn gunk.

This is normal. I have noticed this idea to be relevant on more machines than not be an issue when trying specific prints. The build up did not seem all that bad actually from the photos.

I like the second photo with heatsink. I was unaware that these machines held a heatsink on the hot ends. Good to know…

I have kept it simple. I print flat bases at times and mostly when trying to build components. This takes out guess work on why the machine may fail to be relevant in use cases. For instance, I needed to make a part for a machine, some walk-behind mower, and used the biggest-most-area-portion of the build to be my base.

With more complicated pieces, this gets harder and harder to have the largest area piece as a base.

Anyway, I hope you can remove the blob orientation without further ripping apart the machine.

I had to get a hard piece of metal once to ram down in the orifice of where the filament gets injected to the hot end for clog removal.

Please keep the post alive to post when you have made some headway on the building around the removal of the blob. I always liked to see how people use the machinery and how they fix the machinery when stubborn things take place.

Anyway, so:

a. nozzle off

b. nozzle on

- use the GUI on the machine to heat the hot end

- proceed to remove delicately this blob

With the hot end heated properly, the blob should just wipe off.