I ordered 5 spools of gray hyper PLA from the U.S. Creality store a couple days ago because: US $17/spool when you order 5+.

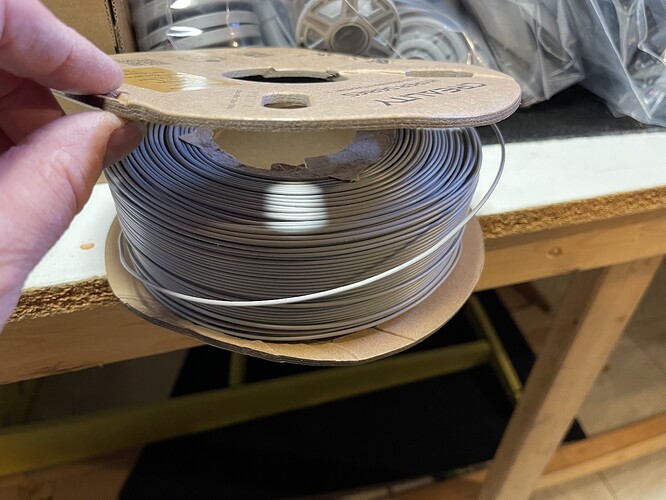

They arrived today and it’s as if FedEx threw the package down 3 flights of stairs.

All the cardboard spools are damaged:

I’ve had some great luck —no issues at all with this K2 (despite FedEx’s best efforts to damage it when they delivered it to my house)—and I don’t want to start having bad luck now.

I can straighten out the cardboard spools, but the damaged areas all have the rigidity of a wet noodle. SHOULD I TRY TO RUN THESE, OR SHOULD I COME UP WITH SOME KIND OF PLAN “B”?

1 Like

There are little rings you can print and clip to the spool. I would not run those as-is in the CFS, they’ll get jammed. Seems to be common enough for someone to have made a diy solution. I had to do this with a roll of their Soleyin. One of the eyes for filament broke. It would wedge on the CFS roller and jam from the CFS gears wearing a groove into the filament. .

I imagine the delivery guys feet must really hurt. Playing football/soccer or kickball with a spool of filament sounds painful. Those things are folded like a used car salesman during Sunday prayer.

Creality Cloud - Creality HYPER PLA/PETG Cardboard Spool Adapter CFS (v2) From Flo-3D 3D Printer Files | 3MF File | Creality HYPER PLA/PETG Cardboard Spool Adapter CFS (v2) | Creality Cloud

1 Like

Thanks for pointing me in the right direction! I ended up printing the 6mm version (These are the thick cardboard spools) that Dmitry linked to. Hopefully, this’ll make these spools useable.

1 Like

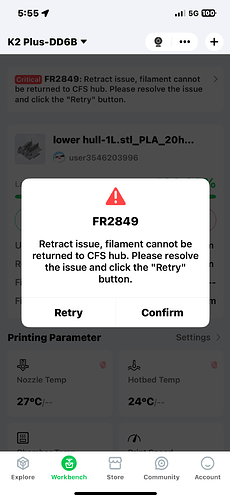

Well, the printed rings was a good try—I’ll have to see what’s going on when I get home from work. I figured the only time these mangled spools would be a problem is during retraction:

Ugh…got home to find this (expected):

What I DIDN’T expect is that slot 2 of the CFS ain’t sounding “normal” now and doesn’t rewind so good either. Sounds as if a gear in the drive mechanism is partly or fully stripped.

I guess I’m going to have to print up a spool winder and transfer all the PLA from the damaged spools to some good empty spools I have lying around.

Damn, that sucks. I would say it returned a LOT of filament to the CFS. I shall join you in casting a long lasting and very itchy pox upon those that inflicted such wanton carnage on your spools. May they scratch for a fortnight and a day. One of the first things I printed was a respooler. The best one I found at the time was https://www.printables.com/model/407688-bambu-lab-p1-x1-x1c-x1cc-filament-spool-switcher-w. Your results may vary, no guarantees expressed or implied etc etc lawyer bs. Only a bit of PTFE tube, skateboard bearings and a few screws. No wood no metal, you may have to glue some of the bearings in. I had a bearing fall out while spooling and the thing kept on going without issue. Do NOT attach a drill or it will get away from you and probably best to clamp it to a table but I get away without that. I have unloaded and yeeted all my sus spools. As to your CFS, some guy on here had an issue with the teeter totter reversing drive slipping and the symptoms sound familiar but that would rely on memory and I have a hard time with what I had for dinner yesterday. He glued the offending shaft to the gear, got new parts from Creality but at that time I read it, the glue was holding and the new parts were held as spares.

Thanks—That was the first re-spooler I considered, but then came across this one that seemed as robust, but simpler in construction:

https://www.printables.com/model/466883-pastamatic-filament-spool-winder-for-bambu-lab-x1c

I’ve got to pull the retract motor assembly out of the CFS and see what’s going on in there, but first I’ve got another 4 plates of gray stuff to print; In the meantime , I’ve set an alarm so I can be there when the prints finish so I can manually assist in rewinding the spools.

If you gently unbend all the ends and fully install into the bands, it must work.

Creality Cloud - Filament Spool Winder 3D Printer Files | 3MF File | Filament Spool Winder (best one) | Creality Cloud

You underestimate how skilled FedEx is at destroying cardboard reels.

Some edges are just bent over—no problem there. Other edges are smashed in a way that turned the cardboard lamination into a stack of soft, floppy paper 8mm thick, which can’t be contained by the rings I printed up.

Hello Safeairone,

Any chance of sending the original photo’s you took to fedex saying,“I want compensation !” ?

Cheers.

I was thinking about that, but I think that ship has probably sailed—I’ve already burned through a spool and a half of this filament on the mangled spools. It’d be like eating an entire entree at a restaurant , then complaining that the food was awful and demanding your meal be comp’ed.

Slot 2 is knackered, but so far, the spool in CFS slot 3 has managed to function OK with the printed rings on the spool. Good thing, too—I wanted to be there to help the CFS retract after the 19 1/2 hour print job, so I set my alarm to be there just before it got finished, but it finished an ENTIRE HOUR early! I can’t believe how far off the slicer and Creality Cloud app are in their print time estimates!

Finally, to wrap up this thread, I only just now realized something obvious—all of these 19 hour build plates are using a single filament. I can just run these mangled spools on the external spool holder.

Ha!—Nope! FedEx made EXTRA sure I wouldn’t be able to run one of the 5 spools they mangled, out on the external spool holder either!:

That is thorough and complete destruction. I found that Creality filament was cheaper at my local Canada Computer store than it was on the Creality website. Sure I have to go get it but it is close, they are well stocked and the spools have that odd round, functional and unrun-over or dropped from orbit quality about them. That being said, filament on sale I have ordered arrived unscathed (FedEx I think) and my printer was pristine but that was not FedEx… I sense a respooler in your near future…

I would have already printed a respooler to deal with this, but for the last 9 days straight, 24 hours a day, the printer has been on a wartime production footing, and manufacturing can’t be delayed (I’m printing a GIANT radio-controlled King Tiger tank for my grandson  ).

).

![]()