hi there i’ve been have a lot off issues with my k1c. many prints keep failing and its had very little use. first layer issues and sometime the extruder will knock the print off the bed. I’ve tried all your tutorials on the your youtube channel like bed leveling reset. I’ve even just purchased a new plate thinking it was the plate but i’m still getting same issues. Its like the first layer adhesion isn’t strong enough.Also getting alot of stringing of the extrude line it does down the left side before it prints. Soleyin ultra Pla. hotend is 220c and bed is 45c

Hi

It would help everyone if you can let us know the following:

Filament used, bed temperature and hotend temps.

sorry though i added that it’s Soleyin ultra Pla. hotend is 220c and bed is 45c

Hi

Are you using glue on the bed?

Try cleaning the bed with isopropyl alcohol first, then try printing with a bed temp of 60 and a hotend at 215.

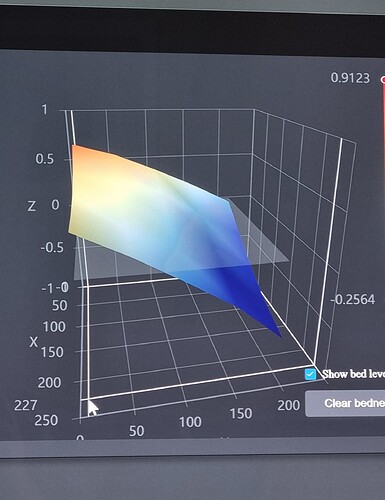

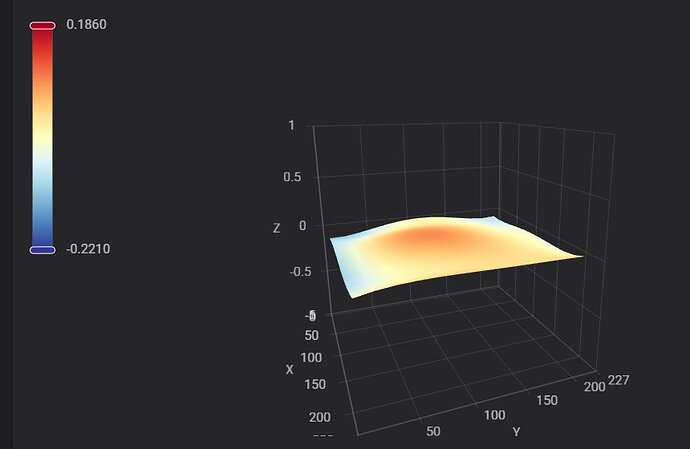

Not familiar with the KC1 printer but looking at your pictures your Z offset could do with being lower.

Try one thing at a time on a small test print to dial in your settings.

Good luck

Ok thank you

Is your filament dry? If you get close to the nozzle you should not hear it hiss or pop. Wet PLA hates to stick.

I did some research on the filament, and It seems like it is very poor quality. You can try to print at 230 or even more. I have had to print very bad PLA at 260 to get it to flow out of the nozzle. What you can do to test it is heat the nozzle up to 220 and push some out by hand. Then 230 and push some out. Note the deference in pressure as you push down onto the filament. When it flows smoothly, this is the temp to use. Also beware, some filaments have hard spots in them. I never run cheap filament anymore, it waste more time than money it saves.

Your bed level is not the problem, but I would stick two .5mm spacers under the back two screws that hold the plate up to get it near perfect.

Ok thank you. I shall give that a try. I have noticed like litte puffs of smoke when i extrude filament through and it looks clumpy. I have a filament dryer but it not connected straight to machine humidity where i live and house is pretty low. Any suggestions on best filament to use.

Hi

Sounds like moist filament but PLA is not usually that bad.

I use ESUN filament from Amazon and have no real issues, but tried others without too many problems.

Store your opened filament in vacuum bags with some silica gel packs and moisture will not be an issue.

Good luck, and don’t forget 3D printing is an art with a big learning curve.

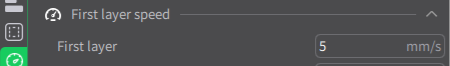

I print my first layer slower for better adhesion

Hi, thats exactly the same problem i had, i tried so many things i was about to give up. Then i tried an older version of slicer, all of a sudden every print was almost perfect, the best thing is to set bed leveling on for every print, the speed is the next problem, set it to 30 for best result, the older version allowed manual addition of gcodes for bed level and other common settings i cant recall at the moment.

If your interested i can update this post with more details next week…

Also you could try petg at 240,65 very good adhesion to a clean plate. Try going without a brim if you have a large base area.

And i also add to my designs a 0.1mm fillet on every edge i can, if makes for much cleaner edge corners.

Last of all, post your gcode, slicer, or cad files if you can.

Wow…hard to get good results when that is the first layer.

I never change my temps (200/60) for PLA.

I never have the machine re-level before a new print.

I use Elmer’s Glue sticks when needed, and

I manually adjust my nozzle height when the first layer doesn’t look exactly right. Don’t forget to “remember” the new setting.

The “sizzling” surely says your filament is wet. It can absorb moisture in a dry room if not sealed. Even brand new sealed packages can arrive “wet”. Does it SNAP easily? That’s another indication of wet filament.

Good luck.

I use Creality hyper PLA and PETG for most of my prints on my

k1c. PLA at 220c bed at 60c speed 250 - 300 m/s , TEPG at 250c and bed at 70c speed 250 m/s.

I only use isopropyl alcohol to clean the bed before printing.

Also your bed level needs adjusting, There are some good you tube vids on how to adjust the bed.

- by adjusting the lead screws.

- By using spacers where be bed connects to the lead screws.

This is my bed graph after using the spacers.

Bill

I run two Creality K1C and one S1 Ender printers 24/7. Check the K1C printers for deformed PTFE tubing pinching the filament. Look at the PTFE tubing where it enters the back of the printer from the filament runout sensor to the chain rail area.

Now come to the dark side, glue sticks are for little children. Wash the build plate with hottest water possible, no dish soap, no alcohol, nothing. Spray a heavy coat of unscented Auqanet hair spray on the build plate, slap the build plate into the printer and print.

After I finish a print I remove the build plate, spray Auqnet where the print was and print again. I wash my build plates every 50 prints or so.

Use the K1C extrude function to extrude some material, after it has cooled, slide it through your fingers, if it is bumpy, you have too much moisture, if it is smooth moisture is not your problem.