I’m new to 3D printing (been doing it for just over a month now) and I have been absolutely blown away by how good this printer is for the price point. However, I have recently come across a problem.

Until now, I’ve only really printed fairly small things. A few days ago I started trying to calibrate my first layer, so I printed a large square, large enough to occupy almost all of my build plate. However, as the print head moves towards each side of the square, there is a visible gap between the lines, yet the middle seems perfect. I have tried playing with the flow and Z-offset, and every time I manage to fix the issue, it causes over-extrusion in the middle of my print which feels incredibly rough, and I can hear the printer nozzle scraping over it on the subsequent layer.

-

I have tried several different brands of PLA (Creality, JAYO, Sunlu and eSun) and still get the same result no matter what.

-

I am using the default Generic PLA profile in Creality Print 6 and have adjusted the nozzle and bed temperatures accordingly for my PLA. Nothing else.

-

I am running the stock firmware (unrooted) and I have done a factory reset.

-

I have recalibrated my printer using the self-test (input shaping and bed levelling).

-

I have confirmed that the bed is square to the frame and gantry is also square to the bed (they are slightly out of square by about 0.02 degrees, which I believe is negligable), so I doubt that this is the problem.

-

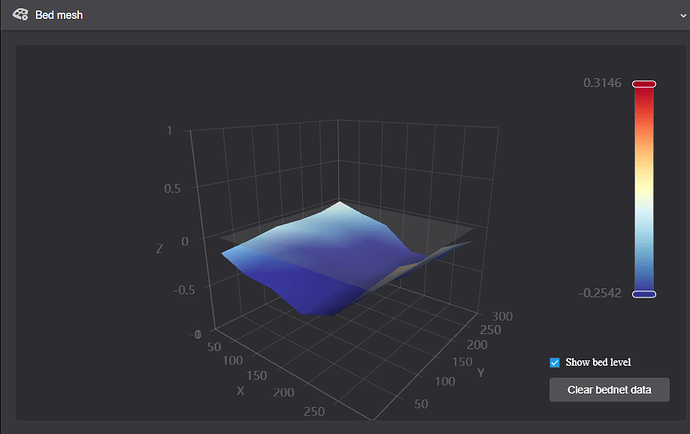

The bed is slightly warped. It dips towards the centre by about 0.4mm, and has done so since the printer was delivered.

-

I have checked that all screws are properly tightened.

-

I have carried out a factory reset.

-

I have greased the guide rails.

-

I am running the latest firmware (1.2.3.23).

-

Belts and runners all seem to be fine.

-

Manually moving the print head all the way to the right takes about 2.2KG of pressure, until about 2 inches from the end of travel when it takes almost 3KG of pressure. I have run the printhead back and forth about 1500 times, since this part of the build plate isn’t often used, so perhaps it needs to wear in? Maybe it’s causing the printhead to lift a little as it gets to the stiff part? I noticed that as the printhead goes back and forth, the X axis guide rails seem to go up on the left and down on the right slightly, and vice versa, depending on the direction of travel. Also, when the printhead stops on the right-hand end stop, it takes quite a bit of force to get it moving before it feels more free. This could be unrelated though, as the issue seems to start several inches before the end stop.

In general, I get the best results with a Z-Offset of +0.3mm. However, the lines separate towards the side of the square. When I lower the Z-Offset to +0.15mm, I can hear the nozzle scraping along the print and it starts to go very bumpy, but the lines stick together at the end and look like they should, but the rest of the layer is terrible.

Something is definitely not right as it should be consistent.

I purchased the Ender 3 v3 Plus so I could print larger prints, but while the print bed is bigger, I can’t seem to reliably print anything larger than I would be able to on the standard Ender 3 v3 rendering my upgrade rather pointless.

Does anyone have any idea as to what might be going on? It’s frustrating as first layer calibration is pretty much the first calibration I have tried to do, and I am defeated before even starting.

Many thanks in advance.

https://drive.google.com/file/d/1yKJSElFK5-VuGvowISpR1EgFQMWU0F_7/view?usp=drive_link

https://drive.google.com/file/d/1W0CqT-0U_x-bjKECIGIS3HNAsA6Pm7gd/view?usp=drive_link