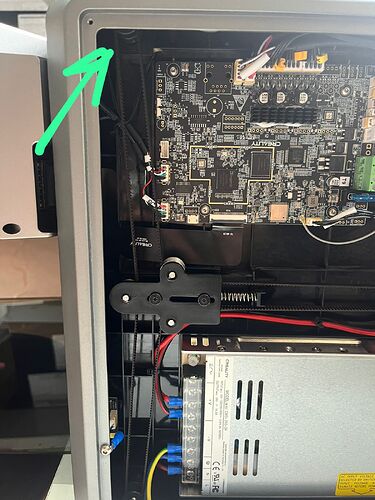

If the belt is not tight enough, the bushing has play and clicks. This is most noticeable during table calibration when the nozzle touches the table, and the table makes a slight downward movement.

ok! I’ll try later and bring the results! thanks! : )

Update: I kept trying different settings and managed to get rid of the noise. However, there was no improvement in the previous situation.

I didn’t read all of the messages so I don’t know if this was tried or not and I know this sounds stupid but have you tried to print the whole print piece? It might not affect the rest of the piece and are you using glue?

jimandyen,

I’m helping someone set up their Creality K1C and it has been a nightmare. This is the second one (1st was a K1). His first got returned after a hotbed failure after only 1 week but the prints were sticking as long as he ran the hotbed at 60 C instead of 45 C. Then the hot bed failed and the printer got returned.

I set the K1C up and all was working on day 1. Creality Ender 3 PLA, The next day I got a phone call that nothing was sticking to the bed, not even its own benchy on the printer. Isopropyl alcohol and glue did not solve the issue. I saw your post and tried the Z offset on the printer. That worked but NO SIGN OF ANY SAVE BUTTON. This was done on 10th Jan 2025 and the firmware was updated during the initial setup of the printer (don’t have the version number handy).

Question:

From what version of the firmware is the save button present?

I then moved on to set the offset in the slicer both Creality Print and Orca. If it is a printer calibration issue it really should be done on the printer! Out the box this K1C printer cannot even print its own benchy from the printer and have it stick to the bed. Filament was Creality Ender PLA. He even bought the filament heater to keep the filament dry!

I printed a first layer and it looked reasonably even thickness across the bed so I don’t think bed warping is the source of his issue.

I ended up with an offset of - 0.04.

I left him happy although I was a bit miffed that Z offsets had to be set in the slicer. It really should be on the printer if the printer is not going to be set up properly in the factory or get knocked off in transit.

Another phone call today 12th Jan 2025. Prints not sticking to the bed. I think I will have to make another trip to investigate tomorrow, I’m running out of ideas. Lets hope another tweak to the Z offset solves the issue. Does the printer have thermal issues making continuous adjustments required just to get it to stick?

This is really not what I expected from a brand new printer. I have an original Creality Ender 3 and have absolutely no problem with prints sticking to that bed. I thought all this autolevelling was supposed to make things better, not worse!

Unlike others this guy is not trying to get some ultra smooth finish on the base of his prints. He is a beginner and just wants something that works.

Next step bed B? If that is the solution then why don’t Creality just ship bed B with the printers. My original Ender 3 has a much rougher surface.

Before someone asks I should have mentioned in my previous post that I have run the calibration numerous times and checked the box when printing to perform the calibration. Doesn’t help.

Hello @Frustrated …! ![]()

Welcome to the Creality Forum…! ![]()

For a start try this printer profile setting as each printer seems happy with it’s own profile…

In Creality Print 5 you can set the z offset setting for each printer:

Hi there,

I seem to have the same problem and setting my Z Offset fixes it. It is a pain that it resets after each print and I cannot for the life of me find a setting in Creality’s slicer to permanently change the Z Offset? I also cannot find a save option on the actual printer to save the Z Offset. Could you help me find either of these please!

Thank you!

Following up on my previous post in the hope that it may help someone else. Prints (PLA) are now reliably sticking to the bed even without glue. Glue supplied with the printer was NOT sufficient to prevent the original problem.

Previously I had put in a Z offset of -0.04. While that worked some of the time it was not sufficient.

I visited the owner of the K1C printer again and made the following changes.

1.) Increased hot end temperature from 220C to 230C. Creality Ender PLA. 230C is actually the Creality recommended temperature for Ender PLA.

2.) Increased Z offset to -0.05 which seems to be the magic number used by a number of people.

Z offset was changed in both Creality Print 4.X and Orca 2.2.0. Z offset can be set in both slicers and both work with the K1C. Z offset change on the printer itself CANNOT be SAVED with the current printer firmware.

3.) Reduced first layer speed and first layer infill speed to 1/2 their default values.

Now which is of these moves was the critical one I do not know. I wanted to leave the user with something that worked so threw everything at it. It now appears solid.

Now a word about slicers. I could not use jimandyen Creality Print 5 solution in this thread to enter the Z offset. This particular users PC is a relatively old PC and Creality Print 5 suffers from frequent Open GL crashes on this PC. It is not usable. Your PC may be just fine. Not to worry though. I ended up using Creality Print 4 which also has a Z offset setting. The OpenGL issues with 5.X are likely due to the particular graphics solution on this particular PC. It was not plain sailing with Creality Print 4 either. The newer 4.X versions suffered from terrible lag on this PC. After it declares it has finished slicing the system can be unresponsive for a minute or more. If you click a button in that time it hangs. The trick is to mouse over the LAN print button without clicking and if it changes colour (responding to the mouse over) then you can go ahead and click and it will work. I resolved this lag issue by going back to an older version on the 4.X branch 4.3.8.6984 which did not suffer badly from the lag. So in this case older is better. That version does not have a profile for the K1C or Ender PLA (before their time) but the K1C profile is very similar to the K1 which is there. You can find out the differences by comparing the profiles in the Creality 6.X slicer.

I did try Creality Print 6.0.0.1078 but that didn’t look to be ready. I could not get a connection to the K1C printer to print although I was able to view the camera on the Device Tab. I also got a Norton firewall warning with 6.X.

I also used Orca 2.2.0 which does have a setting for Z offset and a profile for the K1C. It works fine on the same PC.

Now having to set the offset in the slicer is not ideal. There are cases where you are given some gcode and would like to just print it. In these cases you must set the Z offset on the printer or hack the gcode with a text editor to add the offset.

Bililu, did you ever resolve your first layer problem. I’m having similar results with my K1C

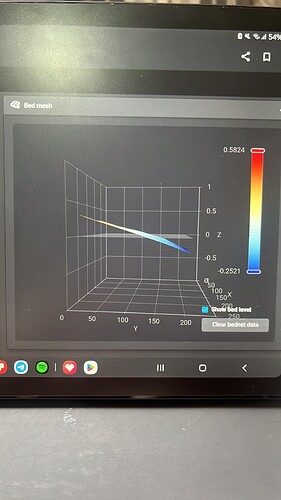

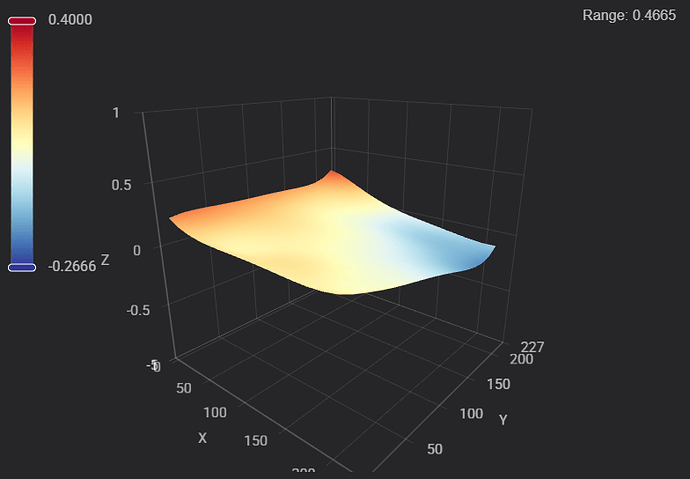

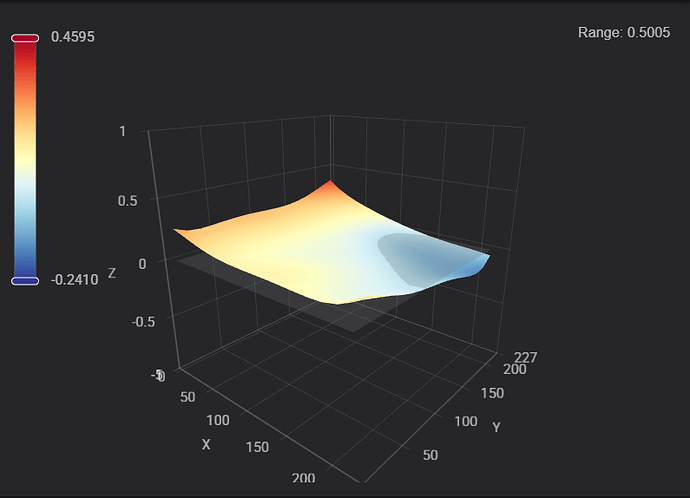

Same issue here. I’ve tried tooth skipping method, print shims to level manually, but looks like my bed is warped.

depends on potluck on what bed quality you got, but can you try setting bed temps to whatever you need for 10 minutes and retry mesh calibrating? seems the sweet spot for it to stablise

Yeah, tried that, 15 mins @ 70 degrees. Results are pretty much the same. I’m starting to consider to replace my hot bed, or do the glass bed mod.

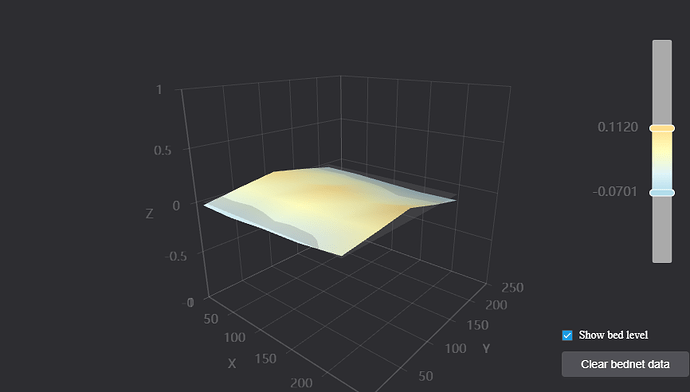

Hi, I also have a problem with the first nar. I calibrated more than 10 times as in the video but it did not work perfectly. I have a problem that in the cent there is +0.11 from the front +0.018 and from the back -0.061. I have pads under the table legs. how can I fix it?

that graph looks like a tilt in the rear z-axis lead screw… get these here in the rear to at least tilt it in the right direction as a new bed is not going to fix a tilt, only flatness.