Last night I started a print - and fell asleep in the middle of it. Apparently at some point during the print, this wonderful glob formed and the noise was god awful.

This is the second time I’ve had something similar to this happen - where there was this mass accumulation of melted filament in the hotend. I am assuming this is the consequence of a clog.

A few observations -

- Prior to both of these times, I noticed what I perceived to be insufficient flow from the hotend.

- I misjudged (apparently) these flow issues to be calibration/tuning issues, and in doing so probably made the situation worse by trying to up the flow to compensate.

- Both of these times have occurred with a third party hotend that I purchased, in order to support higher print temps. It wasn’t a cheap cheap one, but it wasn’t a higher priced one either.

- I don’t really do any kind of hotend maintenance. Print completes, I leave it be until the next time I have to do a print or if I want to change the filament.

So, questions…

- How do you tell the difference between a calibration issue and a flow/clog issue?

- Should I change nozzles frequently/at some regular interval? I pretty much leave them until I think maybe the print quality could improve with a nozzle change, and maybe that’s too long.

- What are best practices on hotend maintenance?

- Once the hotend has done this globby thing - do you think it’s worth disassembling it and trying to clean it out, or no?

Appreciated

I think providing more information about the specific printer, the 3rd party hotend you have, the type and brand of filament you’re printing, etc. would go a long ways to getting you better answers.

1 Like

I have a Ender 3 v3 SE - with a sonic pad driving it.

As for the filament - I used a myriad of different filament types from different brands (usually what I can find on sale in amazon). The specific filament I was using this time was Creality CR PETG, but I also have a fair amount of Kingroon PLA, AnyCubic PLA, other rando PETG brands (GiantARM and others). So during the life of any nozzle there are likely a variety of different brands and filament types flowing through it.

The hotend is an off brand 300 degree titanium heatbreak, copper nozzle installed at time of blockage.

This sort of thing happens when nozzles or hotend come loose leading to molten material getting out where it shouldn’t. Fully tightening nozzles at 1.8-2Nm torque when it is hot to make sure the nozzle is properly seated. Had a loose nozzle and consequent blob of death like this. Checking this and hotend screws once in a while can help prevent this. Is it worth trying to clean this, yes it is. Hot air gun, soldering iron or simply heating the hotend and gently removing the hot plastic being careful of heater and thermistor wires. Should be saveable with patience. Best keep a spare thermistor and heater for the future or look into a different hotend such as a Microswiss which should help alleviate this problem.

1 Like

@Bonfireman That appears to have been what it was. One of the hotend screws had come loose and it had some play on it.

One reason I like the new unicorn nozzle is it’s less likely to develop these issues due to the design.

Okay, so maybe total noob question, but I have a theory as to what was causing my issue and want to see if you guys tell me “derp, you should have noticed that.”

When I bought my printer, they had this special deal of “add some various things”, and I picked some nozzles. Figuring since I got them from Creality, they must be the right ones, I didn’t give it much thought until I just bought some new ones.

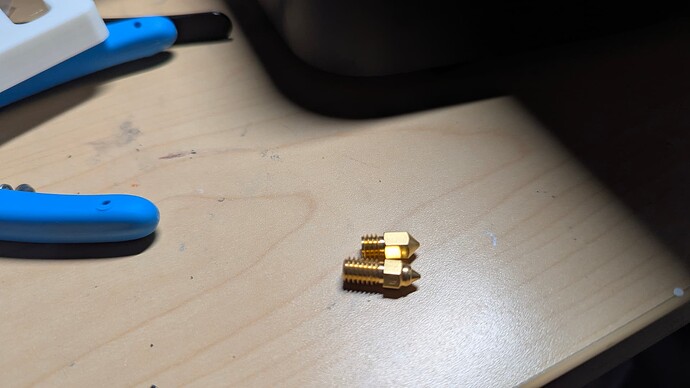

On the top you’ll see the ones I’ve been working with and having these leakage issues with. On the bottom, you’ll see the type that just came in the mail.

Is it that I had the wrong kind of nozzle, that did not properly fill the space within the heating box…which allowed for filament to accumulate until it was forced out the other end?

The top ones threads are too short to seal off, so yes filling the space with molten plastic, its a V6 or MK8 nozzle (seen it called either). The bottom nozzle is a volcano nozzle, there are many others out there to confuse things further. If you don’t already have one a mini torque wrench (mine is 1.8Nm) for tightening nozzles correctly.

1 Like

![]()