Hi,

I have a problem with the glass bed,

after printing a few elements from PLA and later after printing a few elements from PETG, the bed stopped being sticky in the place of all prints.

I cleaned the surfaces after each print, but on the sides of the glass it feels sticky and in the middle there is nothing sticky.

How can I fix it?

But there are no obvious damages to the print bed?

Glass print beds are very sensitive to the temperature used and the perfect Z-offset. How does the first layer look?

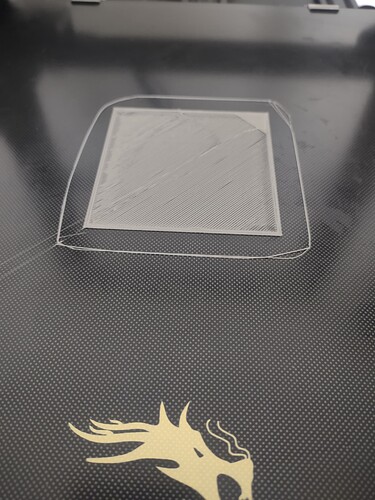

I added a photo of what it looks like.

As for the first layer, yesterday, during one print, the corner of the element lifted.

That should still be fine. Just make 1 layer test print to ensure it has enough but not too much squish.

I cleaned it with kitchen liquid  it’s glass and I can feel that it’s already sticking, but not as good as on the sides of the glass, the inside is still a bit dry, I don’t know how to explain it

it’s glass and I can feel that it’s already sticking, but not as good as on the sides of the glass, the inside is still a bit dry, I don’t know how to explain it

I’m going to test 1 layer, on this area in the middle, and take a photo.

Maybe try some dish soap and then alcohol to clean. We use it pretty regular and works well. Gets off any residue.

I wonder if PETG leaves some kind of residue that needs to be cleaned off…???

Yesterday I did a test of one layer on almost the entire surface and it turned out that one of the corners was too high, so I leveled the bed again.

I cleaned the entire bed with acetone and soapy water but unfortunately it is worse than before.

I can feel that the glass is not sticky and when I started printing, part of the model did not stick.

There is a coating on the bed maybe that’s what is going bad.

If its sticky could be some petg left on the board acetone doesn’t really break it down well. Try cleaning with ipa then break out the PLA again and print a 2 layer square over the affected area at a high temp say 220 ish with a good squish that should bond and help pull up any residue on the bed. Then clean with soapy water dry and then ipa again once it’s back on the printer to remove any oils that may of come from your hands

1 Like

I cleaned the IPA and it still doesn’t stick, and when I did the 1-layer test on PLA 0.16mm

-

It was obvious that it was barely sticking

-

after printing, the entire print came off the bed without any problems, almost too easily.

I will also test one layer, but the filament will be placed in the dryer. Maybe this will change something.

The 1st layer test was performed on the following parameters:

Bed - 70C

Head - 220C

Layer size - 0.16mm

This is what the glass looks like after cleaning.

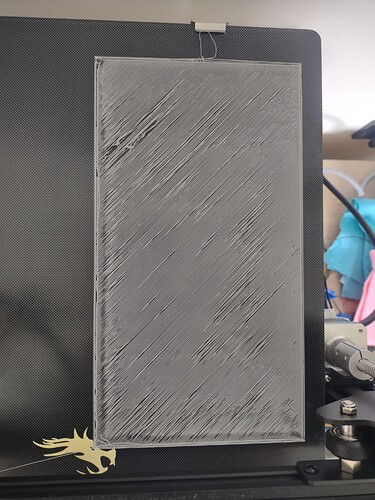

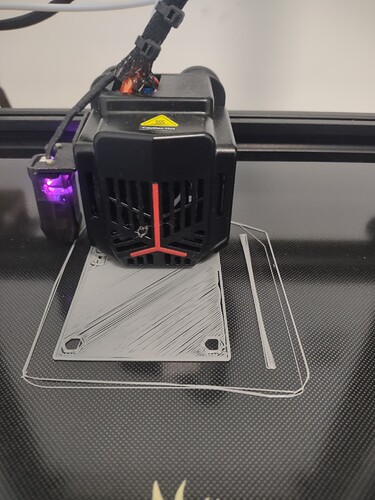

This is what 1 layer looks like,

You can see that it doesn’t stick exactly to the surface.

Too far off, bring the nozzle closer. Maybe try for 0.28mm or so first layers

Check your extrusion rate also. Looks like a little bit of underextrusion. Please check z axis height as mentioned before

You can try a tiny bit of glue stick too. Look around forum to see what people use. I use Elmer’s school glue sometimes. But test on small stuff first on the glass in case it’s hard to remove. You don’t want to break glass. Be careful and go slow when you try new stuff. Glass beds cost money And make sure you read up on using it on glass! Especially with different filaments. Good luck

Hello,

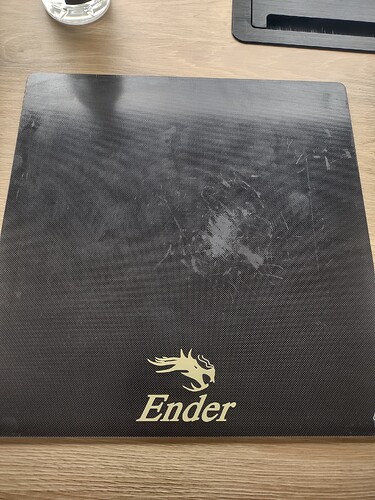

I ordered a new original creality glass bed.

Well, it doesn’t print very well on PLA filament.

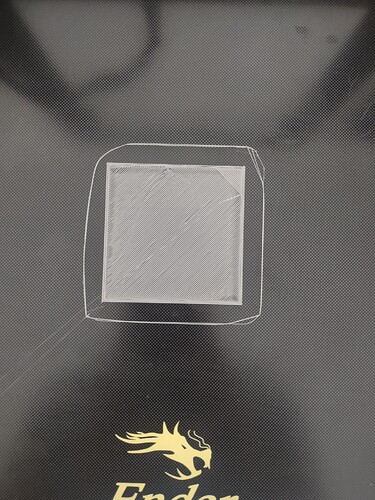

Recently, one corner of the model has lifted and now I am printing a case for Raspberry Pi 5 and the first layers don’t look good.

Once I make this border around the model, you can see that it doesn’t stick.

PLA

bed: 60C

head: 200C

Are you able to help me somehow?

And the bed is new and you can feel the differences.

Looks a little high off the bed mate. Baby step your z down

Today I will calibrate the bed.

I hope it helps

Your bed looks level enough mate as it’s consistently bad  , the z offset is what you need to calibrate nozzle is too far off the bed.

, the z offset is what you need to calibrate nozzle is too far off the bed.

I ordered a feeler gauge, how many mm is best to set?

I use paper to get it close and then print something with a brim so you can adjust of the fly until it looks smooth. Paper is around 0.02 from memory