Handling Closed-Loop Motor Faults: Recalibrating the Motor Zero Position in Fluidd

Background

If the motor is not functioning properly, making abnormal noises, or frequently triggering protection mechanisms, it is possible that the motor’s zero position has shifted. In such cases, recalibration of the motor zero position is necessary. Below is a one-click calibration G-code that can read the motor’s original zero position information and recalibrate it.

Steps

- Prepare the Machine:

-

Disable the motor.

-

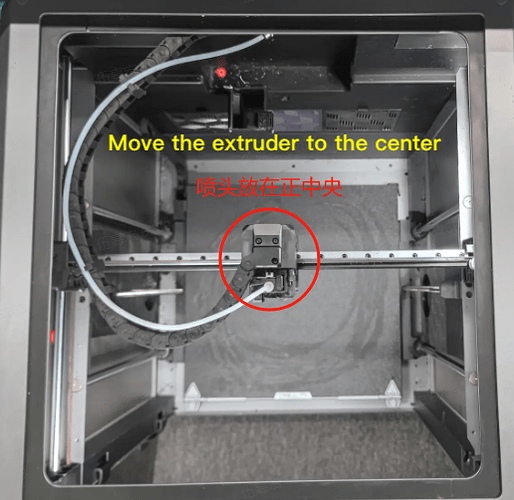

Move the extruder to the center.

-

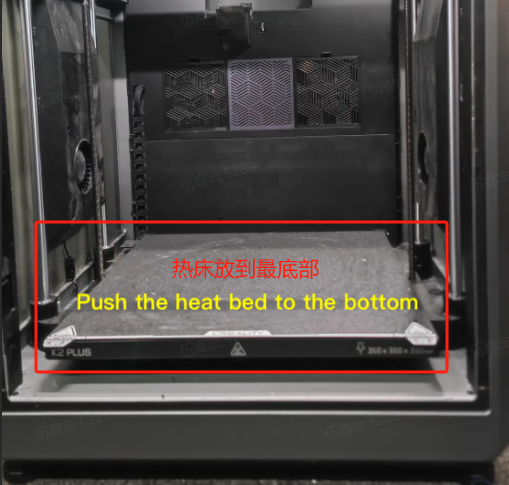

Push the heat bed to the bottom.

- Run the Calibration:

-

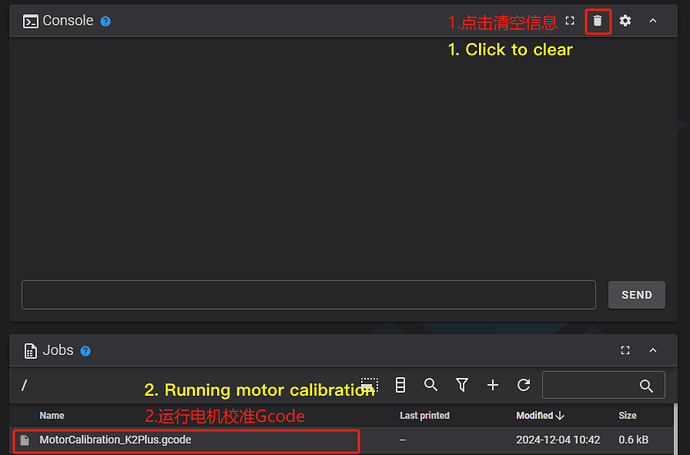

Log in to the Fluidd interface.

-

Execute the motor calibration G-code.

MotorCalibration_K2Plus.gcode (592 Bytes)

-

Wait for the calibration to complete.

- Completion:

- The terminal will print “Done printing file” indicating the calibration is complete.

- Take a screenshot of the calibration feedback information and send it to customer support.

Note: Do not power off the machine during the calibration process as this may cause anomalies!

- Once calibration is complete, you can proceed with other operations.