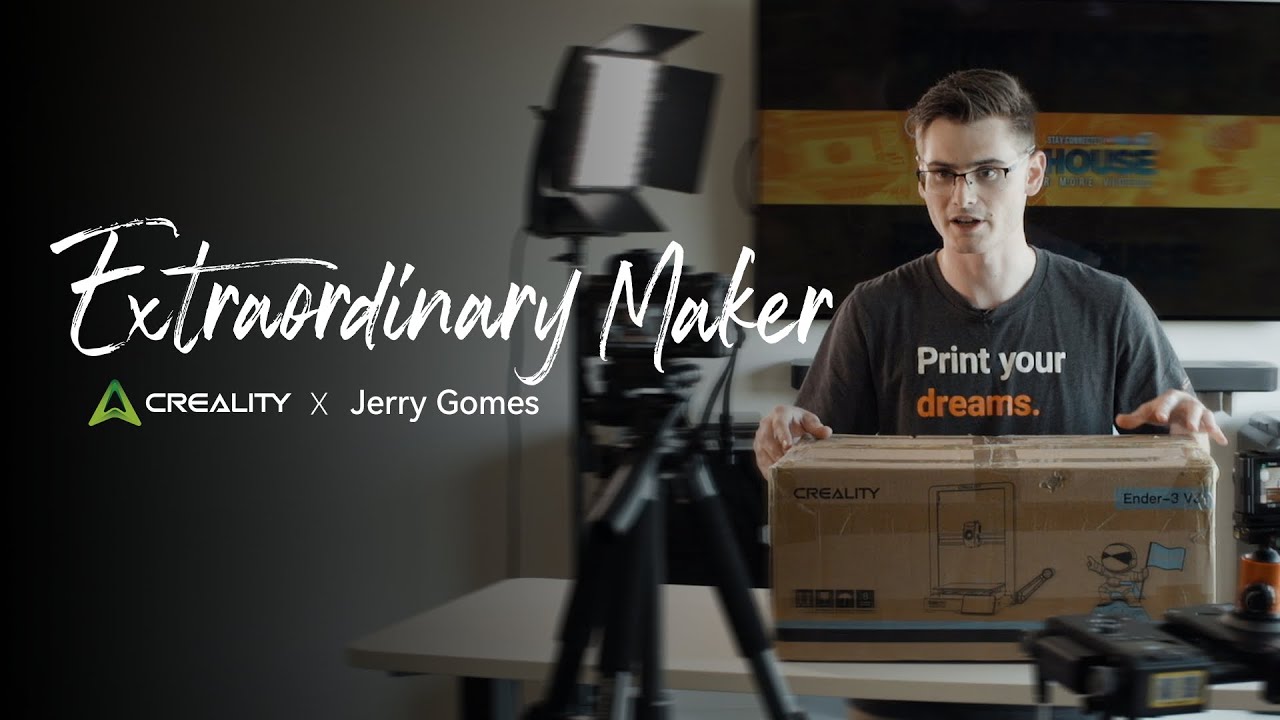

Jerry Gomes, a 27-year-old engineer, has seamlessly transitioned his passion for technology into a thriving 3D printing enterprise and a popular YouTube channel.

Jerry Gomes: a passionate engineer and 3D printing enthusiast

By day, he hones his engineering skills in Huntsville Alabama, but by night, he delves into the innovative world of 3D printing, where creativity meets precision.

His journey exemplifies how 3D printing can empower professionals to push the boundaries of innovation, offering limitless potential for those willing to embrace technology.

Journey into 3D Printing

Jerry’s 3D printing journey can be traced back to 2008 when his fascination with the game Roblox ignited a passion for engineering. While studying Computer science at university, he honed his programming abilities, laying a solid foundation for his future in tech.

It wasn’t until five years ago, upon completing his bachelor’s degree, that Jerry purchased his first 3D printer, the Creality CR-30, marking the official start of his foray into 3D printing. This marked the beginning of his collection, which grew to include five more Creality printers: two Ender 6 models and two Ender 3 V2.

Today, he continues to expand his setup with several printers from the Creality K Series, a lineup he holds in high regard for its versatility and performance.

Jerry and His Creality 3D Print Farm: A Glimpse into His Production Hub

The Creative Freedom of 3D Printing

3D printing has transformed Jerry’s life by providing him with a powerful outlet for creativity, one that aligns perfectly with his engineering background.

Unlike traditional forms of art, such as painting or drawing, which never appealed to him, 3D printing allows Jerry to design and create without picking up a brush. By sourcing models online, he enjoys the process of turning digital files into physical objects, holding in his hands what once existed only on a screen.

One of Jerry’s most innovative projects is a custom-designed capsule that integrates seamlessly into an automatic lawnmower. This lawnmower can autonomously maintain your lawn whether you’re at home or traveling abroad, sticking to its schedule without any manual intervention. However, the mower’s advanced capabilities come with a vulnerability—it can be stolen.

To solve this problem, Jerry developed a 3D-printed capsule that mounts discreetly within the mower, allowing for the storage of a GPS tracker. With this solution, owners can track the mower’s location if it’s ever stolen.

What’s remarkable is that the entire design, from concept to production, was realized through 3D printing. The capsule is custom-fitted to the mower, blending in so well that it appears as if it came from the factory itself.

His engineering expertise also enhances his problem-solving skills, making 3D printing not just a creative endeavor but a practical one. As Jerry puts it, “If it’s a problem I have, most likely someone else has it too.”

This insight inspired him to launch online businesses on platforms like eBay and Etsy, where he offers innovative 3D-printed solutions to help others solve similar challenges during their 3D printing journey.

Building an Online Presence with 3D Printing

The Print House serves as Jerry’s primary YouTube channel for content creation, where he showcases many of the models that fuel his online business. He notes that building a YouTube channel is akin to establishing any other business, both require drive, motivation, and unwavering dedication.

Jerry emphasizes that the passion and commitment needed to cultivate an online presence or grow any venture—be it a business or a hobby—are rooted in the same core principles, regardless of the financial aspirations that may accompany them.

“It is a lot of work and a lot of people, they just see the final result at the end, they don’t see what goes into it.” he explains. As a fervent content creator, Jerry often finds himself filming a single shot multiple times or spending fifteen minutes setting up a two-second B-roll clip.

The same painstaking effort is vital in the realm of 3D printing. The design and manufacturing of 3D-printed models diverge significantly from traditional manufacturing methods. For example, Jerry points out that one must carefully consider intricate parameters, such as infill percentage and perimeter count, along with the type of material used—whether it be PLA or ABS, each with its distinct properties.

Jerry Utilizing a 3D Printing Slicer for Precision Model Design

While guidelines for these parameters are readily available online, true mastery comes from hands-on experience and experimentation with 3D printing.

Despite the allure of this cutting-edge technology, many individuals hesitate to get started, unsure of where to begin their learning journey. Jerry believes this reluctance stems from a lack of confidence in their ability to grasp 3D printing, even though advancements in the latest generation of printers have made it more accessible.

Additionally, the complexity of 3D printing slicer software often deters beginners from fully engaging with the medium. “I believe 3D printing is as popular in the US as it is in other countries, but I think it is still mostly an engineer centric market,” he notes, highlighting the need for broader accessibility and education in this innovative field.

Creality Making 3D Printing More Accessible

Creality aims to bridge the gap between advanced 3D printing techniques and the general consumer, a mission that deeply resonates with Jerry. He admires Creality’s commitment to making 3D printing accessible to individuals of all ages and skill levels, positioning the brand as an evangelist within the industry.

While many printers in the same price range often lack essential features such as user-friendly screens or intuitive firmware, Creality excels in these areas. “One of the great things that I think about Creality is that for the price, they have some of the best possible 3D printers on the market,” Jerry notes enthusiastically.

He is particularly excited about the K2 Plus, which features CFS technology that enables users to print models in multiple colors simultaneously.

Although Jerry acknowledges that some users have encountered challenges with Creality products, he considers the brand to be the most reliable option in the budget 3D printer segment. He firmly believes that Creality is on the right path to making 3D printing accessible to everyone.

Not only can individuals of all ages enjoy the experience of 3D printing, but Jerry also sees potential for integrating this technology into everyday life.

“When I started 3D printing five years ago, it was really difficult to get into the hobby unless you had a technical background. But now with so many resources available, it really lowers the barrier to entry and allows users to chase their creative freedoms.”

Jerry Collaborating with Creality – Interview and Filming Team in Action

As a devoted technology enthusiast, Jerry continually seeks the latest advancements, and his 3D printing business represents one of the most significant milestones in his technological journey.