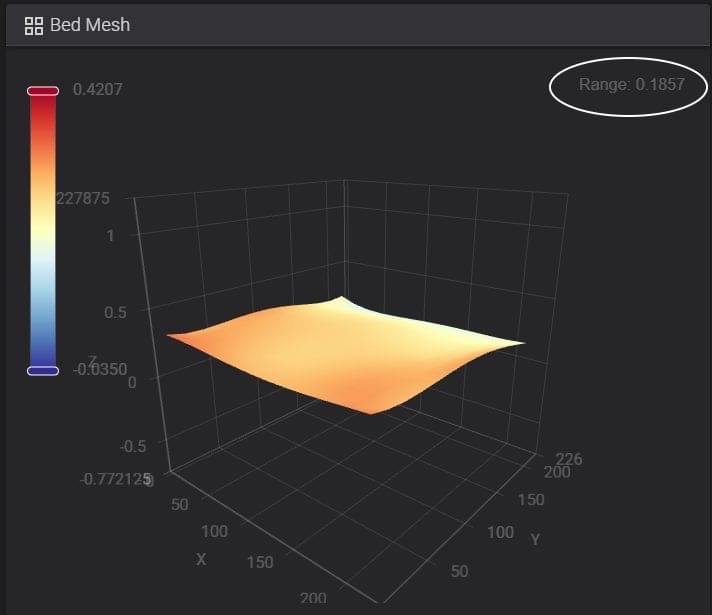

I have had nothing but difficulty printing a reasonable first layer for a very long time. I just cant get it consistent. It seems good at the end of one day and in the morning it is almost time to start over. I have done this several times. I’m beginning to wonder if maybe the bed leveling sensor is just not good enough. I did three tests just now and wrote down the values for the center 9 positions that it reads and some are very off. Is this a problem? or should I just look somewhere else.

[ 7, 8, 9, 12, 13, 14, 17, 18, 19]

-.03, -.07, -.04, -.09, -.07, -.01, -.03, .01, .02

-.07, -.02, -.09, -.09, -.01, -.04, -.01, .07, .01

-.11, -.05, -.01, -.07, -.06, -.13, -.03, .01, .00

Range

.09, .06, .09, .03, .07, .13, .03, .07, .03

I picked the center most locations because most things print in that center block. As you can see 6 of the 9 spots vary by greater than .05mm.

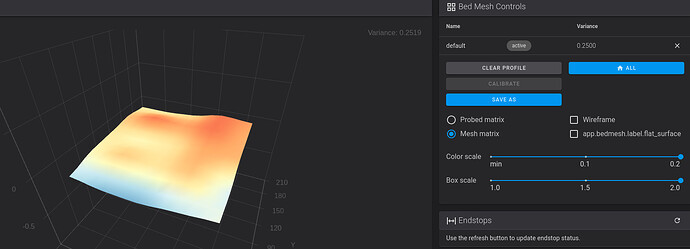

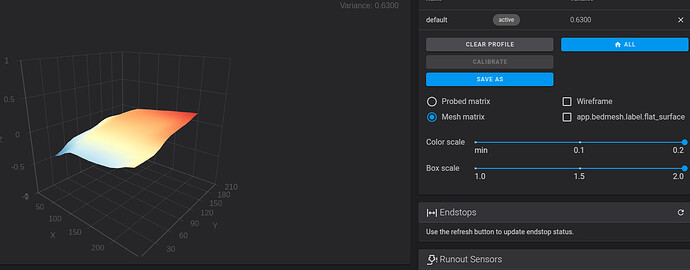

This all really started when I added the Sonic Pad to my printer. I have not had even reasonable results since then. When I look in the ,cfg files The numbers for the mesh and the number for the z offset don’t even look close to what is shown on the sonic pad, the sonic pad doesn.t even show a number for the z offset.