Have you ever wondered about the square barcodes that unlock a digital world with a simple scan? These are known as QR codes, or “quick response codes,” a technology born in 1994 initially for the automobile industry. Today, these 3D printed barcodes are not confined to paper but have found a unique application in the world of 3D printing.

Whether for accessing digital menus in restaurants, connecting to Wi-Fi in hotels, or even providing proof of vaccination, 3D printed barcodes offer a durable and innovative solution. However, it’s important to remember that once a QR code is created, its information remains permanent. This article will guide you through the fascinating process of creating your 3D-printed barcode.

- Step 1: Generating the QR Code

- Step 2: Setting Up for Printing

- Step 3: Printing & Post-processing

- FAQs about 3D Print QR Code

Step 1: Generating the QR Code

Creating a 3D-printed barcode starts with the generation of the QR code. This crucial first step involves selecting the correct data — URL, text, or image — you want your QR code to represent. Online platforms like qrcode2stl come into play here, offering an intuitive interface for users to input their desired data and customize the ensuing 3D-printed barcode. Adjustments can be made to the model’s dimensions, including its shape width and additional features like text labels or functional elements such as keychain holes. This level of customization adds a personal touch to the functional QR code, making it a digital access point and a piece of personalized tech.

After fine-tuning the design to your liking, the model can be saved as an STL file, laying the foundation for the next step. This method bridges the gap between digital information and physical representation, creating tangible, scannable items that carry a myriad of potential uses in everyday life.

2D to 3D

Transitioning from a 2D QR code to a 3D printed barcode may seem daunting, but it’s a seamless process with the right tools. The key lies in choosing a file format that preserves the quality of the QR code regardless of scaling.

SVG files are perfect for this task due to their vector-based nature, which ensures no loss in detail when resizing. Once you have your QR code in SVG format, converting it into a 3D printed barcode involves utilizing 3D modeling software or platforms specializing in this transformation. This step elevates the QR code from a flat, two-dimensional form into a tangible object and opens creative possibilities. From embedding QR codes into custom-designed objects to creating functional yet stylish 3D printed accessories, the ability to bring 2D codes into the 3D world adds an innovative layer to how we interact with digital data. It explores how traditional QR codes can be integrated into physical objects, enhancing their utility and introducing a new dimension of interaction.

Step 2: Setting Up for Printing

Preparing to 3D print a barcode involves more than just hitting the ‘print’ button. The preparation phase is critical to ensure the final product is aesthetically pleasing and functional. Slicing the STL file to generate G-code is the technical heart of this process. This step translates your design into precise instructions that guide the 3D printer on how to layer the material. Calibration is critical here; a well-calibrated printer is essential for producing a 3D-printed barcode that scanners can read accurately.

Moreover, tweaking the print settings, such as speed, infill, and layer height, can significantly affect the outcome. Slowing down the print speed ensures the intricate details of the QR code are captured, while adjusting the infill and layer height can enhance the durability and scalability of the printed object. These settings ensure the 3D-printed barcode looks good and serves its intended function.

Step 3: Printing & Post-processing

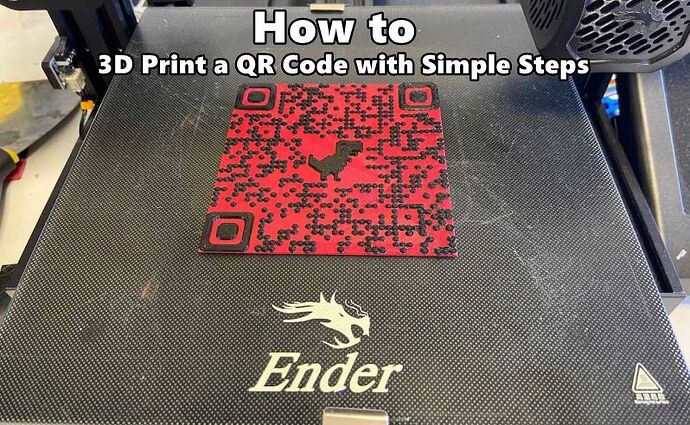

The culmination of your journey towards creating a 3D-printed barcode is the actual printing and subsequent post-processing. This final phase brings your project to life, translating digital designs into tangible, functional QR codes. The selection of contrasting colors is pivotal, ensuring your QR code stands out against its background for optimal scalability.Whether opting for multicolor 3D printing techniques or hand-paint your model, the aim is to achieve a distinct contrast that enhances readability by scanning devices. Let’s delve deeper into the two main methods for achieving this contrast.

Multicolor 3D Printing

Multicolor 3D printing presents an efficient way to incorporate different colors into your 3D printed barcode without the need for post-processing painting. This can be achieved by manually changing filament colors at specific layers or utilizing advanced dual-extrusion 3D printers. These printers can handle multiple filaments simultaneously, allowing for a seamless integration of contrasting colors. The essential advantage here is its precision and uniformity, ensuring that the QR code is distinguishable from its background, which is crucial for scanability.

The process requires meticulous setup in the slicing software to ensure that the color change occurs at the correct layer, making the technology behind multicolor 3D printing an integral part of producing a high-quality 3D printed barcode.

Painting

For those without access to multicolor 3D printing capabilities, painting the 3D-printed barcode by hand is a viable alternative. This method involves applying paint to the raised surfaces of the QR code, which requires a steady hand and patience to avoid overpainting into the recesses that form the code’s background. The advantage of painting is its level of customization, allowing creators to use an extensive palette of colors beyond what’s available in printer filaments.

However, precision is critical; the paint must be applied to preserve the QR code’s integrity, ensuring it remains scannable. Tools like sponges or airbrushes can help achieve an even coat, minimizing the risk of obscuring the code.

FAQs about 3D Print QR Code

1. What materials can be used for 3D printing a QR code?

Various materials can be used for 3D printing a QR code, including PLA, ABS, PETG, and nylon. The choice of material depends on the intended use and durability requirements of the QR code. For outdoor use, materials with higher UV and moisture resistance, like ABS or PETG, may be preferred.

2. Can a 3D printed QR code be scanned by any smartphone or QR code scanner?

Yes, a well-designed 3D printed QR code can be scanned by most smartphones and dedicated QR code scanners. The key factors for ensuring scannability include maintaining a high contrast between the QR code and its background, ensuring the size is sufficient to be captured by a camera, and optimizing the embossed or engraved details to be clear and recognizable.

3. How do I design a QR code for 3D printing?

To design a QR code for 3D printing, you can start by generating a QR code using an online QR code generator. Ensure the design is saved in a format compatible with your 3D modeling software. Then, import or recreate the QR code design in your 3D modeling software, converting the 2D image into a 3D model with raised (embossed) or engraved (debossed) patterns. Before printing, adjust the depth of the embossed or engraved details to ensure the QR code can be scanned easily. It’s recommended to run a test print to verify scannability.

Conclusion

Creating a 3D-printed barcode, specifically a QR code, marries the digital and physical worlds innovatively and practically. From the initial generation of the QR code to the final touches in post-processing, each step requires careful consideration to ensure the final product is aesthetically pleasing and functional. This guide has navigated through the intricate process, highlighting key considerations and techniques to aid you in producing a 3D-printed barcode that stands the test of utility and design.

As 3D printing technology continues to evolve, so does the potential for creating more intricate and functional 3D printed products. Remember, the quality of your final product heavily relies on the precision of your 3D printer. For those embarking on this journey, companies like Creality offer a range of 3D printers that cater to various printing needs, ensuring that your creative visions can be brought to life with the right tools. Whether for personal use, business applications, or simply as a creative endeavor, 3D printed barcodes offer a unique blend of technology and artistry, opening up new avenues for digital interaction and physical representation.