I’m using this filament for the first time:

https://aurarum.com.au/shop/aurarum-pa12-cf15-nylon12-3d-printer-filament-carbon-fibre-1-75mm-1kg/

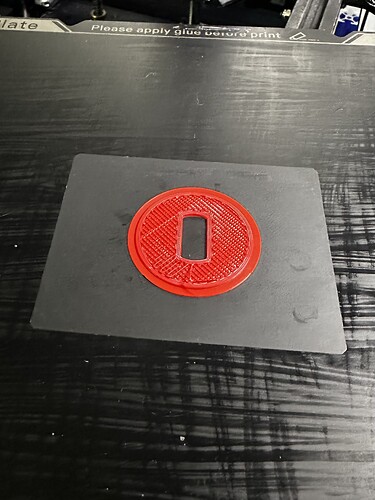

I cannot get the filament to stick to the stock bed even with glue applied - it does not stick at all!? I just end up with a bunch of spaghetti moving around the bed with the nozzle.

I had to create a new Creality Print filament profile with these settings:

Nozzle Max: 240

Nozzle Min: 200

Chamber temp: 70

Nozzle first layer: 230

Nozzle other layers: 220

Bed temp- Smooth PEI plate (Stock plate)

First layer: 90

Other layers: 80

No cooling for the first 3 layers

Min fan speed: 30

Max fan speed: 60

CP settings:

Layer height: 0.2mm

First layer height: 0.3mm

First layer speed:

First layer: 50 mm/s

All other speeds set to 50 mm/s

K1 is about 3 months old.

CP is version 5.1.4

Model is: https://www.thingiverse.com/thing:763622/files

I had to create a new Creality Print filament profile with these settings:

Nozzle Max: 240

Nozzle Min: 200

Chamber temp: 70

Nozzle first layer: 230

Nozzle other layers: 220

Bed temp- Smooth PEI plate (Stock plate)

First layer: 90

Other layers: 80

No cooling for the first 3 layers

Min fan speed: 30

Max fan speed: 60

CP settings:

Layer height: 0.2mm

First layer height: 0.3mm

First layer speed:

First layer: 50 mm/s

All other speeds set to 50 mm/s

K1 is about 3 months old.

CP is version 5.1.4

Model is: https://www.thingiverse.com/thing:763622/files