I’ve had my k1 max a little more than a year now and it worked great for about 4 months and I used it multiple times a week then. It sat for about 2 months before another print and now I have about a 5% first layer success rate(but not a good first layer).

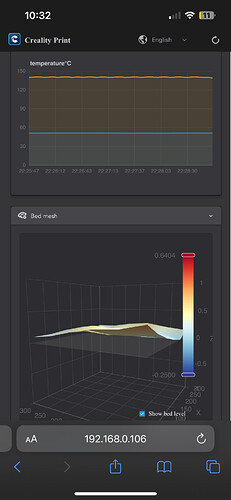

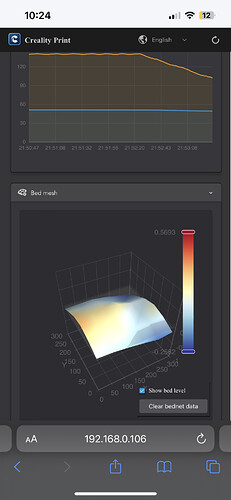

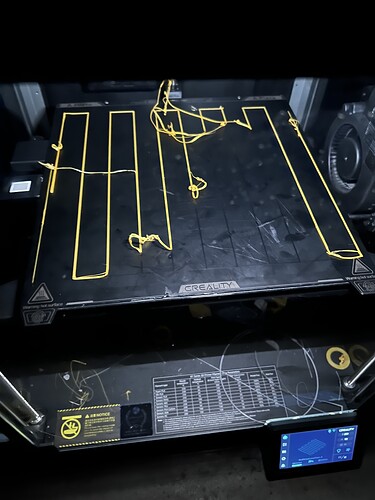

I think the printer is not compensating or adjusting correctly for autolevel. The nozzle is far from the surface on parts of the plate and too close where it can’t extrude(I hear the clicking of the filament not pushing through). Here is everything I have tried to fix this issue:

- Switch nozzle and confirmed its .4mm.

- Added glue for adhesion.

- Factory reset

- Tried prints on updated software and older software

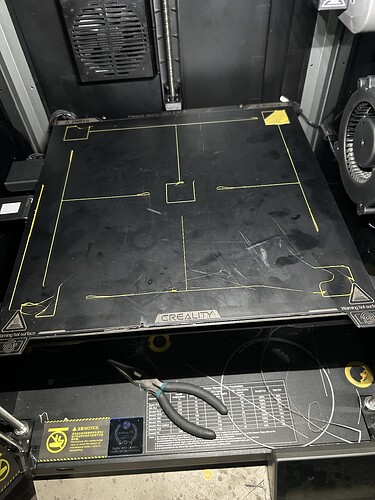

- Swapped build plate

- Heat soak bed before starting print or auto leveling

- Cleaned build plate with soap and water

- Adjusted 3 arms with shims

- Tooth skipped(one of the last things I tried as I’m desperate now)

- Added tape underneath build plate( bed range was within .3mm across plate)

- Tried different slicers(orca,creality,cura)

- Adjusted z offset(-.01 all the way to -.1) this worked for some prints roughly but still had areas that the nozzle wasn’t close to build plate

- Crealitys bed adjust tutorial(taking bottom off and tightening belts)

- Trying default k1 max slicer settings

- Tightening & loosening build plate screws

- Checked for loose or wobble parts, checked for over tightened parts

- Printing full sheet first layer to determine where attention was needed for plate.

- Tried different filaments, ensured it is dry