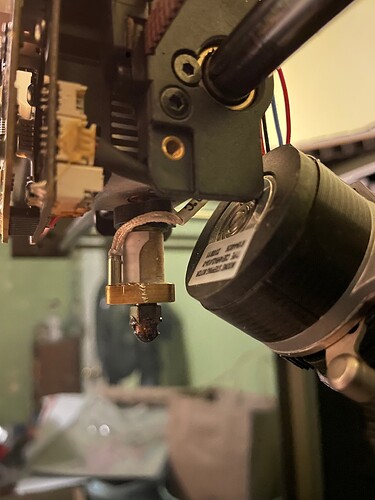

From the image you provided of the failed hot end, I can see the failure mode is identical to mine, which failed only after maybe a 100 hours of printing. The cylindrical ceramic heater element has two pads for the connection of the heater wires. In order to withstand the 320+ degrees C maximum temperature rating, those connections must be welded, or brazed.

What seems to be happening is one of the welds is failing and a wire comes adrift, leaving the heater element open circuit. This is obviously a quality control problem for the manufacturer of the ceramic heater element (with wires attached).

Goodmorning to everyone, I have a K1 Creality.

Since a few monts during the printing, I see that during the print the filament no longer comes out of the extruder in a continuos way but comes out in sections and more precisely in points… and it happened randomly during the print. Sometimes after this problem the filament no longer comes out of the extruder and the printer fails, sometimes this problem persist for 1/2 layer and after that the filament return coming out of the extruder continuously.

I have changed 2 times the extruder, I changed the extruder board … but nothing happened.

During the problem I see the motor is working but the filament doesn’t move.

I use my k1 without lid and the door open to avoid high temperature.

The printer always works with a room window open to change the air and improve the coling.

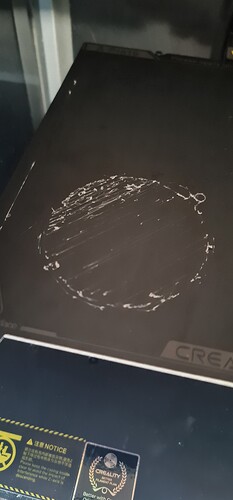

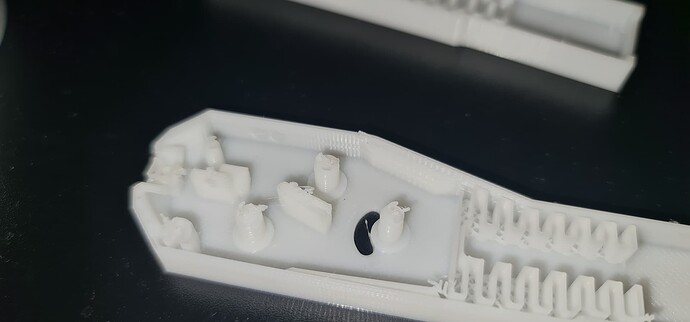

You can see in the photo a cup in which after 1 /2/3 layer problem the print restart, in the other photo the print fails and u can see a discontinuos print, some points of filament around the piece before failing.

I don’t know what to do…

Thank you very much

I’ve had a similar issue with CPrint missing, altering layers in the print, especially 1st layer. Take a look at your preview after slicing to see if any misinterpreted layers are present before printing.

What version of CPrint are you using?

Try a different version or slicer to see if the solution is software based (as mine was) and go from there.

Hope it helps,

Cheers!

Hi. How do I go about getting a new hot end? I have used (and then broken) the spare that came in the box.

Also how big a mess am I in. The hot end got gummed up and in the process of taking a look at things, I broke the white plastic collar (with two wires attached) and I can’t budge the hot end (I did unscrew it). I assume hardened PLA is preventing me from pull it down. I haven’t tried heating it up since I didn’t know what that wire is supposed to do.

Any suggestions?

Thank you for any advice.

Kirke

Heya! Welcome aboard!

Yes, heat it up, otherwise you have concrete. PLA can be brutal but still softens with heat. I’ve used a torch, with no ill effects.

Hot end components are designed to deal with heat and you can find replacements on amazon, ali express, ebay, and, of course, creality’s site.

If you are going to salvage it, you will need a torch, pliers (vise grips, 2 pair, imo), and a cup of water. Heat the nozzle up to a dull red and once free, drop it in the water. The sudden cooling should pop the PLA free.

Give that a shot and please let us know how you made out. Any other ?'s you have, don’t hesitate to ask!

Hope it helps!

Thank you for the advice and encouragement.

The part I broke is just part of the hot end which is (as discussed at length in this forum) essentially a consumable anyway?

I have removed the two vertical screws from the hot end. Is there anything else I need to do besides apply heat and force at this point? I don’t want to break some other part in the process of pulling the hot end down/out.

Kirke

@Zerquetch thank you for the encouragement! I ordered a new hot head and it was fairly straightforward (if fiddly) to replace. First test print is going well, so I think I’m back in business.

Kirke

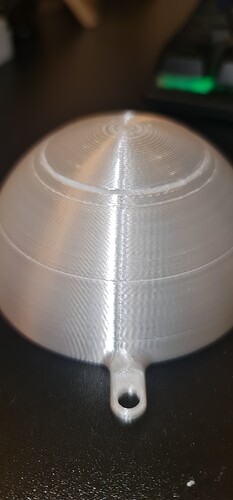

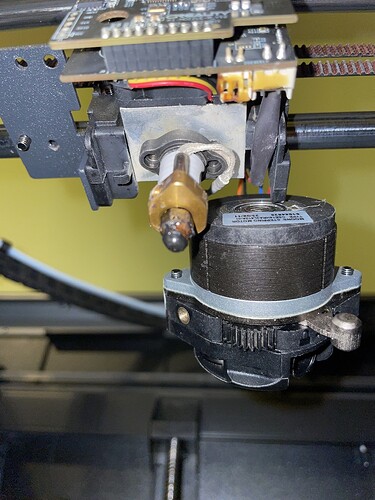

Maybe I spoke too soon. Did I reinstall the fan backwards? It’s super loud now. Can you tell from this pic if I need to flip it around?

Same problem here, the whole heat sink got covered in pla. Got the machine working after melting it down. But later, the nozzle clogged up, so I decided to replace it with the set provided with the K1 Max. Most of the process is described in the video on YouTube https://www.youtube.com/watch?v=6nCiiKYpmC8&ab_channel=3DRundown . But my nozzle is stuck, after I have released the three screws.

Any idea how to loosen the stuck nozzle after removing the screws?