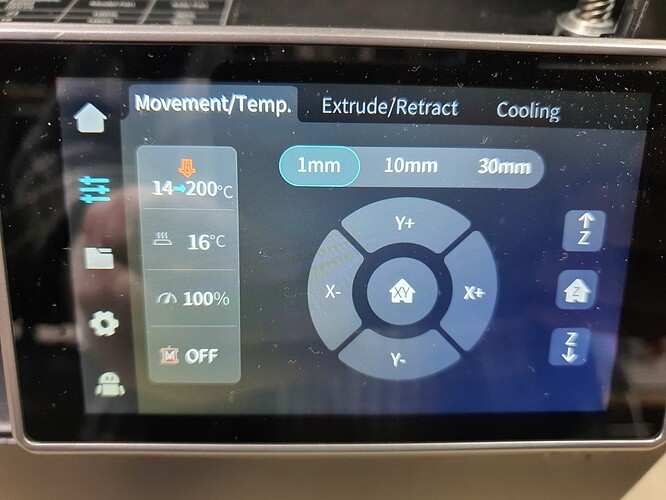

about to fit my 3rd K1 Max hotend, fortunately a spare was in the original box purchased end December 2023, so two hotends in 6 weeks???

anyone else having this issue, the K1 is used around 10 hours a day.

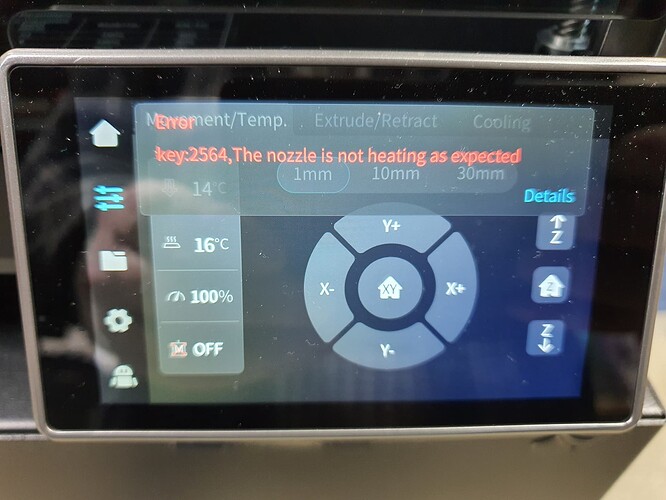

Also a side note if i fit the top glass cover it causes the filament tube to rub on the underside, it has caused extruder issues in the past so i had to remove the cover. see attached image of the hotend error and the filament tube

Ensure that the thermistor is not damaged in anyway and if you are printing with PLA then keep the lid off to stop the extruder/printhead from getting too hot.

The latest version of the hotend should have a red silicone sock and are supposed to be more reliable than the black sock variant.

Mine did the same thing rubbing on the glass top… I usually don’t use the top during a print anyway as @Nikoli said it makes the chamber temp too hot for PLA.

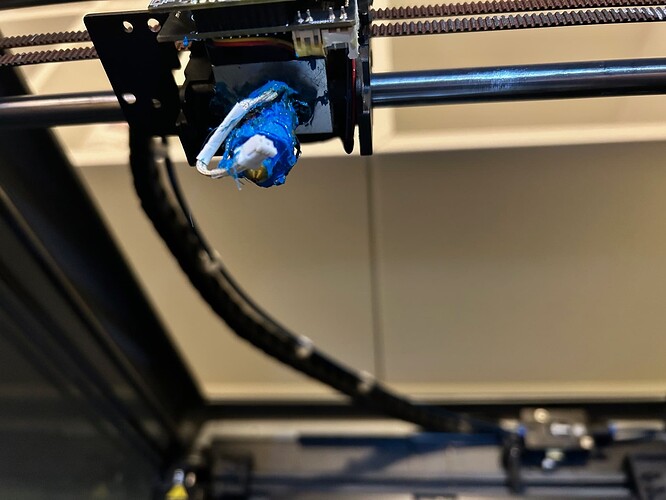

My problem is the chain hangs a little to low and hits the metal rods. ![]()

Found some nice risers here. I put the glass top on when I’m not using it.

Not sure if this would be the problem but are you using some kind of thermal paste. You can see in this video there is some on the part they are putting back in the extruder.

Yes i used the thermal paste.

will fit the new hotend tomorrow and see what happens, appreciate your help.

Shane

Not sure if you have tried any of the chain fixes but sometimes removing 1 link from the chain prevents it from sagging and touching the rods. Another option which works well is the bowden mod which involves removing the bowden tube from the chain and clipping it on which tends to prevent the bowden tube pushing the chain down, here is a link to one of the chain clip mods (should work for both the K1 and K1 Max)…

Interesting, will certainly take a further look.

as for the Hotend, new part arrived and fitted, hopefully will last more than 3 weeks ![]()

Hope so. Let us know… ![]()

You might have mentioned it and I missed it but where did you buy the hotend from…?

Bought from that online retailer that shares its name with a famous Brazilian Rainforest.

£30.99 for a genuine Creality however its the black shrouded one.

I have replaced 3 hotends since August on my K1 Max. Usually due to a failed print that gums up it up and breaks a wire. I just consider them a consumable part.

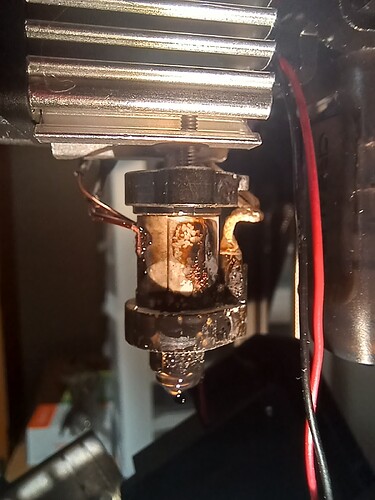

Speaking of hotend failures…

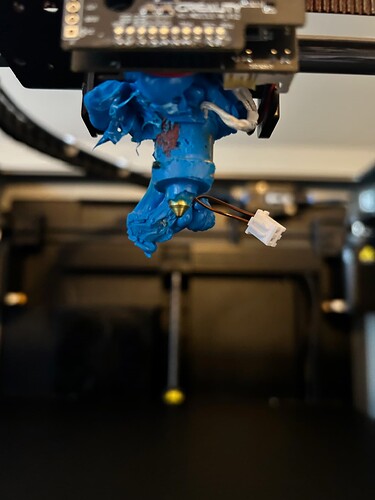

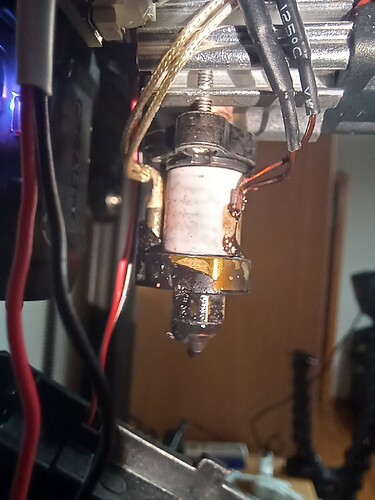

Has anyone had this problem? I have managed to completely encase my hotend in PLA and now it is welded to the heatbreak. In the second picture I have attempted to clear some of the PLA with a soldering iron, but still can’t get the hotend loose to replace it.

only thing you can do is melt your way to the two long screws that hold the hotend and the small one at the back of the heatsink. then try wiggling it out.

sorry for the upcoming joke.

but

"normally you print on the bed "

good luck

Thanks. No apology necessary. I earned that one.

Are heatsinks replaceable? Failure is always an option when I’m doing repairs. I’m worried about stripping out the tiny screws.

I was wondering what would cause that. Do you think the screws on the heat sink got loose with all the heating and cooling down…??

I haven’t cleared enough PLA to see for sure, but that is my theory as well. It does seem like the plastic is coming out between the heatsink and the hotend.

Ok, ive had the same problem on a CR10-SE.

either the screws came loose or the last hotend you fitted was not pushed fully into the heatsink.

check / replace the bowden tube , make sure its the same length as the original.

Make sure the rear heatsink screw is loose enough, fit the hotend and secure not too tightly with the two long screws, as you can bend the hotend bracket, or distort and cause the hotend to be offset from vertical. Then tighten the rear heatsink screw firmly, then slightly tighten the two long screws.

also ensure you use heatsink compound.

I had mine do that but not nearly as bad (that definitely takes 1st place).

I just heated the nozzle to around 240 and during the heating I gently pulled on the filament and most of it came off. After that I took an old and very well washed rag with virtually no lint and cleaned the rest off. Looked like “new” again and printed fine.

I’m not sure how much you’re going to get off on the upper part but how much worse could you make it? You’ll definitely want to get that off because it will start to smoke (mine did at least) and it doesn’t smell that nice. ![]()

How do I put the sock on the new print head?

Carefully! It’s bloody hot!

Actually, for the sock, just wait till it cools down, much less painful!