Hello,

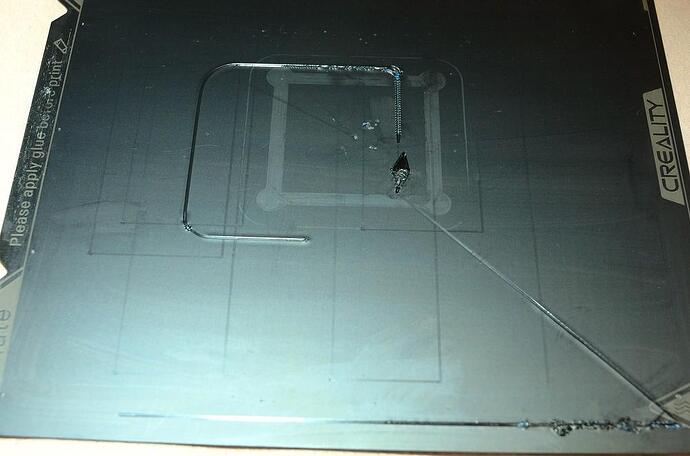

my roughly one year old K1 just managed to rip off the coating of it’s buildplate. I tried to print something, heard rather loud clicking/scratching sounds, stopped that thing right away, and then saw the buildplate having deep grooves along the path that the printhead took, which have even ripped off the entire coating in some spots.

What do now? I could just replace the buildplate, but if it’s a faulty device, this will just result in two destroyed buildplates instead of one.

Also, is it possible, to just smoothen that thing with sandpaper, add glue to it, and print on it’s bottom side?

Thanks

I just made a picture to showcase what has happened.

In essence, I have this printer since the end of last year, and have printed maybe 3 kilos of filament, so it’s not worn down. I’m mostly printing casings for electronics that I’m developing and designing myself, which takes a long time, so I’m really not using it much overall.

On the picture there are marks that the printer left on the plate on two different occasions. Last spring it left the minor marks during bed-leveling. It didn’t stop at the measuring-points, but just ran through without measuring, and then I’ve stopped the device. Afterwards it seemingly ran fine, so I thought of it as just some fluke, and ignored it. I used it on maybe two occasions since that instance, and both times things worked as expected. I had some problems with print-quality, that have to be fixed for my upcoming project, so I tried to print a couple of calibration-towers. One of these towers was meant to get a good value for linear advance, so I entered some TUNING_TOWER commands into the shell, and printed a couple such towers. The first two printouts were unusable, because the slicer overrode some acceleration values which made the printouts invalid, and on the third attempt the entire buildplate was destroyed.

I don’t know what else has been damaged while the nozzle dented in the hard surface of the buildplate, and would like to know, if the issue can be fixed for sure. To me this looks like a fundamental flaw in the built or design of that device, which in a good built would be impossible to happen. Since it has happened twice within a couple of instances where it has been used, it seems likely, that it will happen again. When considering it’s price, that thing has cost me more than 100 bucks per kilogram of printouts, which really makes me hesitate to throw more money into repairs, that might very well fail.

Think creality can respond here how they solve or do nothing.

What do you mean?

Also, I’ve examined the lesser scratchmarks a little closer, and it seems that these must have happened on three different occasions, not just once. But I only noticed it happening once.

Hi to everyone! Dame issue with my k1 Max and only 5 h of Printing.

Contected cistomer care Creality for the problem and i’m waiting response

Hey Fenjus,

thanks for writing I’ve been wondering, whether I’m the only one with that issue. Let us know, how the customer care replies to you. I’ve contacted them too, and in my case they fell silent for the third day now.

Hi, received now notification about replace building plate in warranty!

Check the Z-axis, limit switch, and belt on your printer for any signs of wear or damage. Ensure that the Z-axis moves smoothly and the limit switch triggers correctly, as these issues can affect the filament’s path. If not, replacing a new build plate might not resolve the issue, and the same problem could recur, potentially damaging the filament

Mod Edit: Removed Marketing Link