Hi it would appear that over a 100mm by 100mm print in the X Y axis an error is creeping in. The accuracy appears to be losing 0.5 mm per 100mm of travel.

Is there a way to improve this?

How did you measure it? With prints, are you also sure they are not overextruded since that would give a similar effect.

I measure it with verniers.

I am making mounting boxes for PCBs.

I simply made a basic box in Fusion 360 with the holes in the correct places, however when printing the holes are too close to the origin. It’s not that the holes are the wrong size, they are in the wrong place

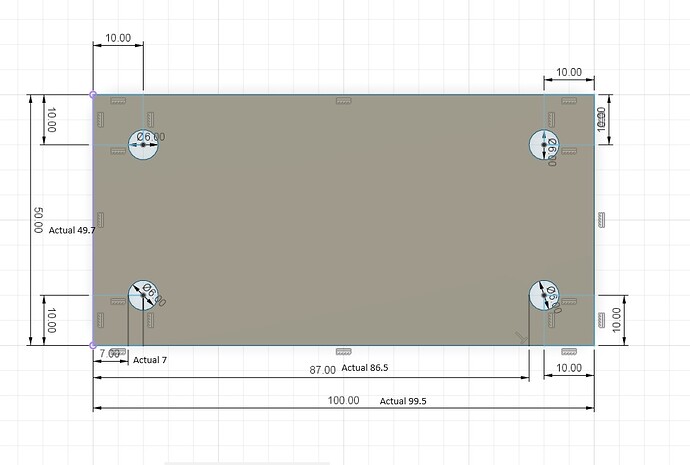

I will try printing out a rectangle 100 by 50 with holes at specific points and give you the measurements.

Please see the attached image with the as designed verses the as measured using vernier calipers.

Could that be shrinkage?

I was an Inventor user. Is Fusion parametric? I’m guessing yes.

If the holes are constrained to the outsides of the box you could just change the overall box dimensions and allow for the shrinkage.

Just guessing.

I don’t have a K1 or K1Max but have used a K1

Jim

Hi Jim,

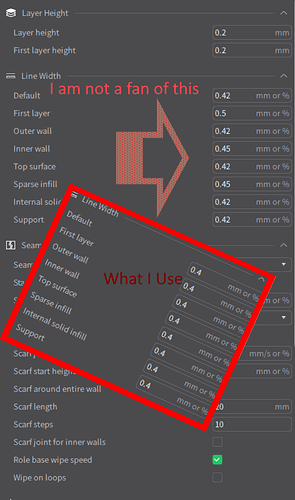

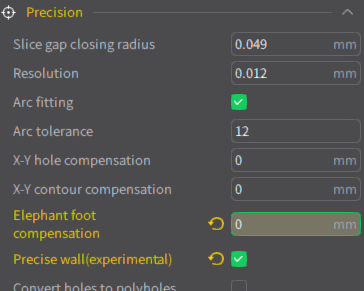

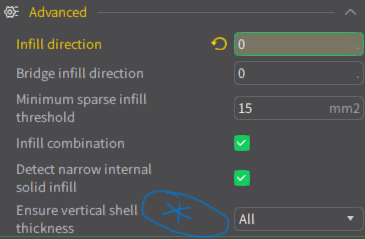

There does not appear to be a fudge factor in the creality print software.

However, I would expect the printer steppers to be accurate to at least 0.1mm over 100mm.

If the print shrinks by that much I’d expect it to come of the plate.

One of the reasons I’m asking here is whether there are other who know how to adjust of calibrate for this issue.

I do have a K1C now.

Wow! I’m delighted with it.

I gave my old DaVinci AIO to my Son & Grand kids with some ABS filaments in the special cartridges. I have more ABS filaments on spools which I’m keeping. The K1C works great with them!

I just ordered £120.00 worth of filaments this morning as well.

WoW! Wow! Wow! What a machine. ![]()

Jim

I’m having exactly the same problem with my PCB enclosures (boxes), printed on my K1 with ABS. If I just print a basic frame with four posts (bosses), to align with the PCB mounting holes, the resulting printed part is accurate, i.e. PCB mounting holes line up with the posts (bosses) on the printed part, but if I print the complete box, the K1 is printing about 1% undersize in the X axis, and the mounting posts of the printed part don’t line up with the PCB mounting holes. If the PCB mounting holes are (say) 100 mm apart in the X axis, a 1% error equates to an inaccuracy of 1mm ![]()

It seems like the K1 is not designed to produce engineering parts that have accurate dimensions.

Do I REALLY have to scale the model in Creality Print before slicing it, to take into account the dimensional errors in the X and Y axis?