Hi everyone,

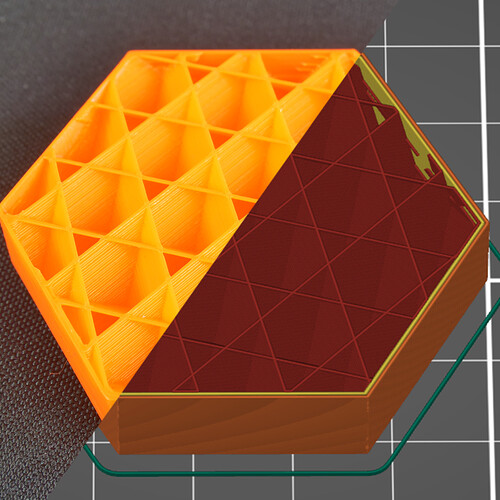

I’ve noticed that some infills in my parts like ’ Adaptive Cubic’ seems to float. Is it just a feeling and is this normal behavior? Or is it a wrong setting on my part?

I don’t think this is the case when I look at the pictures of "Adaptive Cubic " infill on Internet. Here are a few examples:

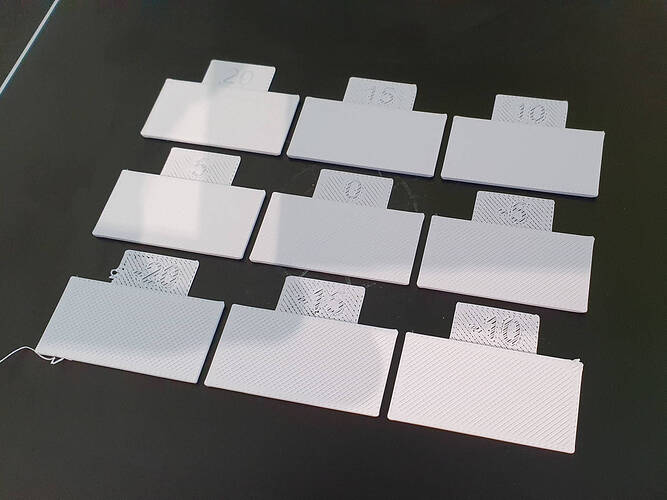

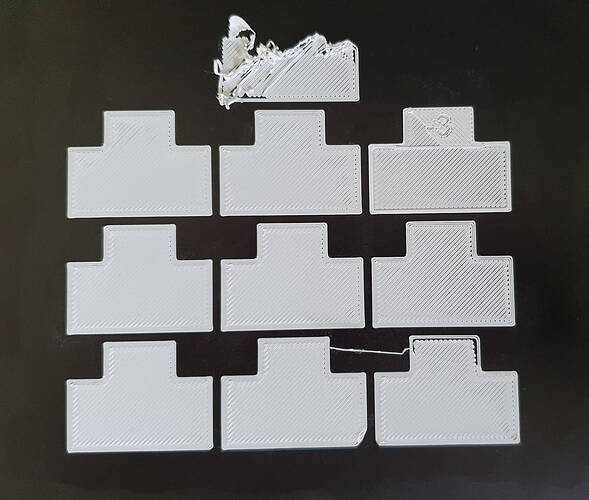

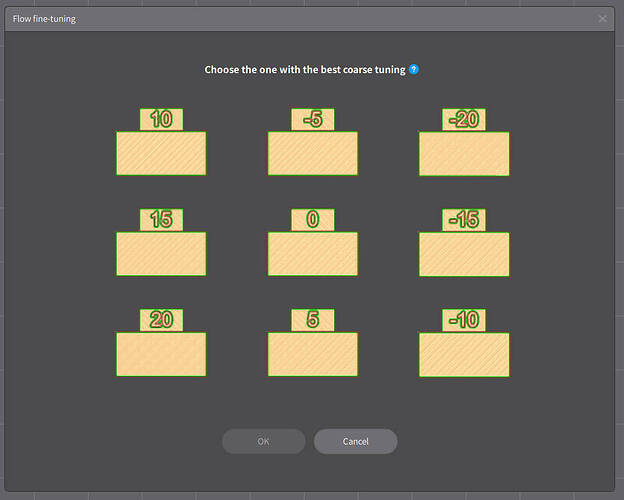

I did a Flow calibration test.

The first pass went well and I think the best result is ‘+10’.

But I didn’t let pass two go all the way, the first layer went peanuts for the ‘0’ value, which seems very strange to me since, if I’ve understood correctly how this second pass works, the object printed with the ‘0’ value should correspond to the ‘+10’ of pass 1, so normally just as good?

I’ve also noticed that there’s an inconsistency between the printing order of the first pass tests and the ‘fine-tuning’ selection choice for pass two (an inconsistency that isn’t present in the Creality wiki tutorial). Could this have had an impact on the running of the second pass and explain the poor result?

There’s also a small mistake in the Flow Ratio change formula on the wiki: “Formula: Optimum Flow Ratio = Step1 Flow Ratio + Step1 Flow Ratio + 100%” should be “Formula: Optimum Flow Ratio = Step1 Flow Ratio + Step2 Flow Ratio + 100%”.

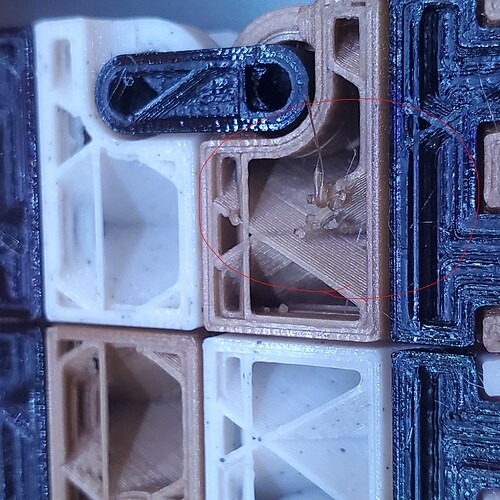

I also have a second issue with my larger prints: the walls come away from my part at the junction between the first and subsequent layers. But for the next layers, the walls remain in one piece. This is where it always breaks.

I am using ‘Easyfil ePLA’ filament from FormFutura at high speed: 300mm/s. I had one conclusive test at 75% print speed and another with the same problem at 75%.

Thanks in advance for any help ![]()