Hello there,

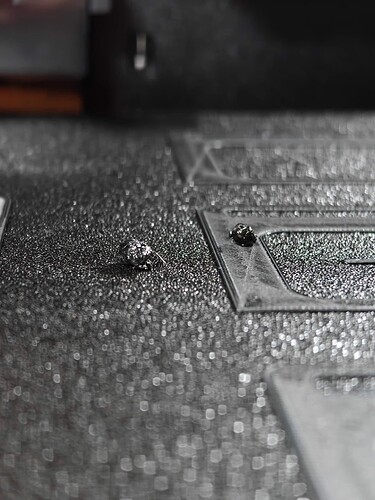

We recently got a K2 Plus with CFS just for printing functional parts out of black PETG. I’ve had several issues getting the system to print well including extruder jams, poor dimensional accuracy, print to print precision, and calibration issues. I’ve been able to solve all the above issues (mostly by switching filaments and doing extensive testing and calibration), but I have one remaining I cannot seem to solve: nozzle buildup leading to clumps of PETG shedding onto the build plate. If these clumps happen to fall on the prints, they often will bond enough and the print be ruined. The PETG on the nozzle also adheres to new layers while printing, messing up dimensional accuracy and print quality.

I’ve done everything I’m aware I can for this:

- Removed the hot end and remounted, ensuring all screws are tight

- Run Auto bed calibrations before every print (would prefer not to, but that’s where we’re at)

- Calibrated z-offset So. Many. Times! (Settled on a value of .05mm. If set higher than that, my first layer is underextruded/comes out poor with gaps between lines)

- Calibrated my filament’s temperature, pressure advance, flow ratio, and max volumetric speed)

- Overture Black PETG, 250C, .13 PA, .92 FR, 11 mm3/s MVS

- Enabled “Avoid crossing Walls”

- Experimented with Z hop when retracting and disabling wipe while retracting, but this causes stringing issues and didn’t seem to help

- Changed first layer height to .28mm, and others to .24mm (from default .2mm for both)

From what I can tell, this buildup seems to occur on layers 2-5. There is no build up after layer 1, and I’ll often pause after layer 5ish to clean the nozzle and any chunks (sometimes there are chunks, sometimes not, even if it’s the same item being printed. It’s weirdly inconsistent). If I do that, the print usually comes out great with minimal buildup after that.

I know PETG is sticky and there are non-stick treatments for nozzles and such, but I’d prefer not to go down that road, as that seems to be sidestepping the real issue. I print these same parts with my BL A1 with the same filament and similar settings, and I’ve never had any nozzle build up, ever.

I’m really hoping I’m missing something obvious. Does anyone have any ideas for me? Please and thank you!