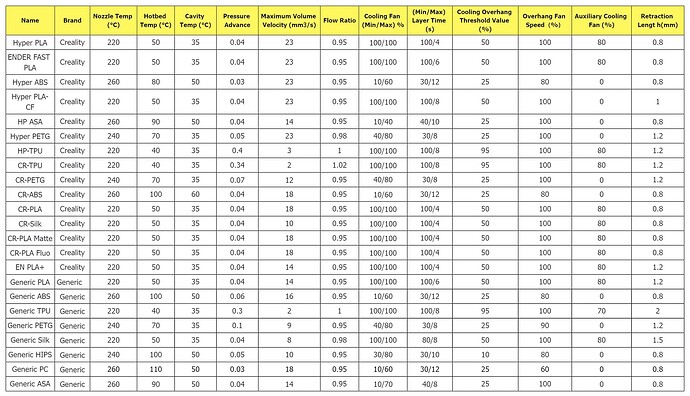

K2 Plus Recommended Filament Parameters

1. Introduction to Key Filament Process Parameters

2. Precautions

2.1 Drying process:

It is recommended to dry the filament before use and keep it dry during use to improve print quality, especially for materials such as PETG, TPU, CR-Silk, CR-PLA Matte, ENDER FAST PLA, and PA (nylon). For detailed procedures on filament drying.

Print Effect without drying VS Print Effect with drying

2.2 Warping and Cracking:

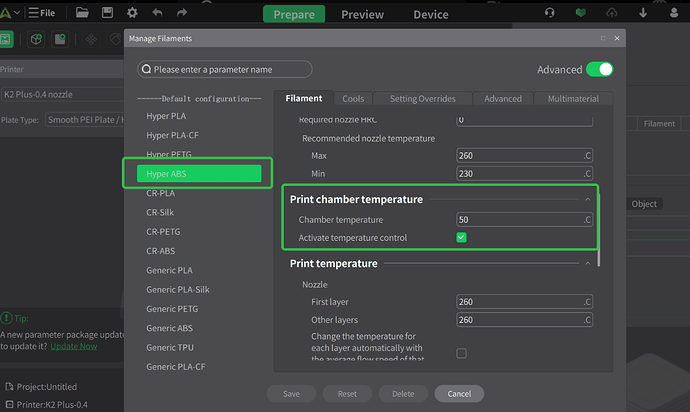

Generally speaking, materials such as ABS, ASA, PC, and PA are prone to warping and cracking during printing due to their characteristics. Therefore, it is recommended to take appropriate measures to avoid such issues as much as possible. In Creality Print slicing software, the default parameters for these materials have enabled the chamber heating function, typically set to 50-60°C, and it is necessary to close the top cover and front door during printing.

2.3 Precautions for TPU Material

Do not use Creality CFS to feed filaments like TPU, as they tend to bend in the CFS tube, causing extruding and retraction failures.

TPU with hardness of 80A, 75A, 70A (or lower) is not recommended for printing on Creality printers, as it is too soft and can be flattened by the extruder gear, causing nozzle clogging.

To ensure print quality and stability, it is recommended not to print TPU-type filaments directly through the PTFE tube, as the resistance of the PTFE tube will increase, affecting the final print result.

2.4 Carbon Fiber Reinforced Material Printing

When printing carbon fiber (CF) reinforced materials such as PA-CF, PAHT-CF, and PET-CF, it is not recommended to use a 0.2mm diameter nozzle to avoid clogging. As the nozzle diameter increases from 0.4mm to 0.6mm, and then to 0.8mm, the printing precision decreases, but the probability of clogging gradually reduces. It is recommended to use a 0.6mm nozzle as the first choice, followed by a 0.4mm nozzle (suggested layer height between 0.15~0.3mm, with a maximum print speed of about 100mm/s). Before using these materials, it is advisable to set the nozzle temperature to 280-300℃ and clean the nozzle interior with a cleaning needle to remove any residual filament, reducing the risk of clogging during printing. If clogging occurs during printing, perform this cleaning operation to ensure the nozzle interior is clean before reprinting. After printing with these materials, if switching to other types of filaments (such as PLA, ABS, TPU, PETG), it is also recommended to perform the above operation.

2.5 Default Filament Process Parameters

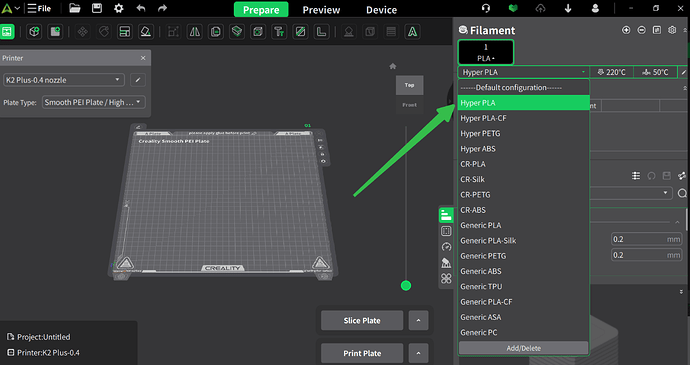

It is recommended that you directly use the default filament process parameters for printing. CrealityPrint has built-in parameters for over 40 types of filaments. If the filament you are using is not in the default list, please select a configuration that is similar to the filament you have for printing.

3. Explanation of Process Parameter Application Scenarios

3.1 Standard process parameters (0.20mm Standard@K2 Plus):

Default parameters for 0.4mm nozzle, regular layer height, average layer lines, balancing print quality and efficiency, suitable for most general printing scenarios.

3.2 Fine process parameters (0.08/0.12/0.16mm Standard@K2 Plus):

These are high-quality parameters. Compared to the default parameters for this nozzle, the layer height is smaller, layer lines are less noticeable, print quality is higher, but printing time is longer. Not recommended for multi-color printing of larger models.

3.3 Fast process parameters (0.24/0.28mm Standard@K2 Plus):

Compared to the default parameters for this nozzle, the layer height is larger, layer lines are more noticeable, print quality is lower, and printing time is shorter for some models.