TL;DR: Increase nozzle temperature by 5-10 C and reevaluate the performance. Admittedly, this is the long method because the results may not be experienced for many print iterations over time, if at all.

The more scientific approach

I do not have direct experience with this specific filament, but I do have extensive experience diagnosing nozzle clogs. Clogging is easy to describe and frustrating to isolate, because it can have multiple interacting causes.

Your post is missing several pieces of information that matter for diagnosis:

- Actual nozzle temperature

- Exact filament a link - not a description - to the exact web page where you purchased that specific spool would help.

- Any calibration steps already performed

Based on the symptoms you describe, a plausible hypothesis is matte filament. Matte filaments typically achieve their surface finish through particulate additives (commonly silica, talc, or similar fillers). These additives have three relevant effects:

- They disrupt the surface finish so light scatters, producing a matte appearance.

- They reduce inter-layer adhesion relative to standard PLA.

- They can interfere with internal melt flow, increasing the likelihood of partial clogs.

The last two issues are often mitigated by higher nozzle temperatures and proper flow calibration.

Nozzle temperature

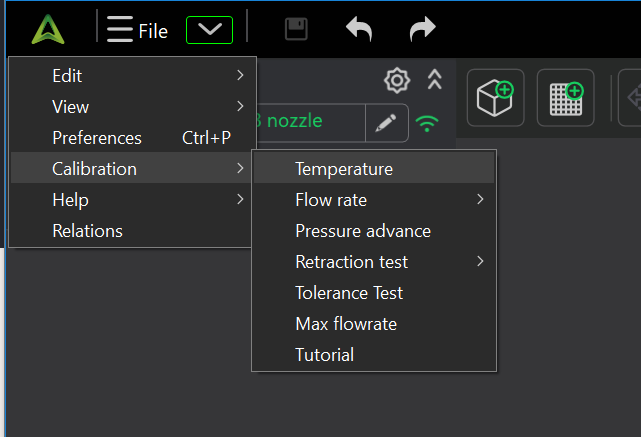

This is one of the few cases where a temperature tower is genuinely useful. If you are willing to print one, post:

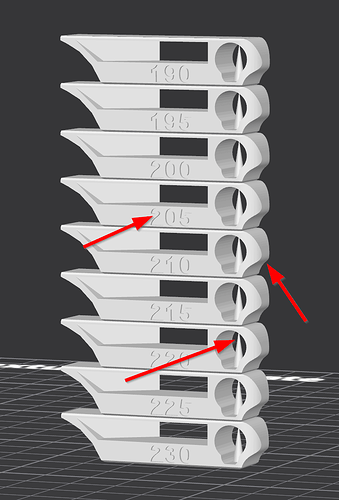

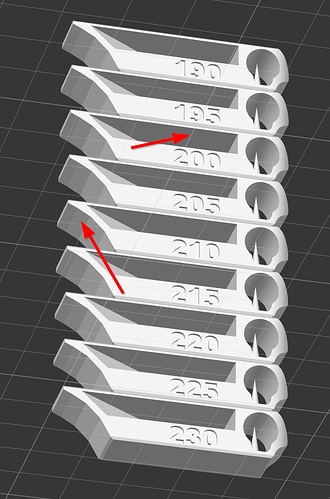

- Two photos of the printed tower

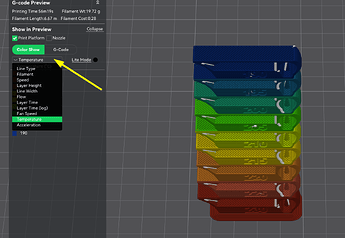

- One screenshot of the sliced model showing the temperature transitions

I’d be happy to help you analyze the visual data and offer up what the optimal temp for that filament should be. Don’t be surprised if you find that for less string, one temp is optimal, while for tighter overhangs, another temp is optimal. I’ve often had to set up more than one filament profile for the same filament to achieve optimal results depending on the print I was trying to accomplish (i.e. accurate parts vs visually appealing).

If the sliced model does not show the expected rainbow temperature bands, you are either using the wrong model or the G-code was regenerated incorrectly.

Photography guidance

Take photos from farther away and use digital zoom to minimize parallax.

Orientation 1: Upright view showing lettering, backside edges, and spires.

Orientation 2: Model upside down on a flat surface to show overhang behavior from below.

Before printing, verify the sliced preview shows clear temperature segmentation:

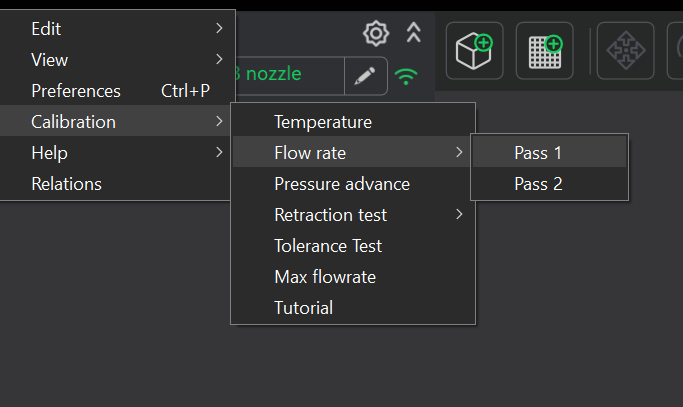

Flow calibration

After selecting an optimal temperature (this is inherently subjective), perform flow-rate calibration. Pass 1 is usually sufficient. Pass 2 can provide incremental improvement but often yields diminishing returns.