3D printing has revolutionized manufacturing, enabling us to create complex designs with relative ease. However, the final product usually comes with visible layer lines, which can make it look less polished. PLA (Polylactic Acid), a commonly used 3D printing material, is known for its ease of use and environmentally friendly nature.

But, like other 3D printed materials, PLA prints can also benefit from post-processing to achieve a smoother finish. In this article, we’ll delve into PLA smoothing techniques to help you improve the appearance of your 3D prints.

What is PLA

PLA is a biodegradable thermoplastic derived from renewable resources like cornstarch or sugar cane. It’s a popular choice in 3D printing due to its low shrinkage rate, ease of print, and good surface detail.

However, achieving a smooth finish can be a bit challenging due to its low heat resistance.

Why Smooth PLA Prints?

Smoothing PLA prints can enhance the visual appeal and improve its feel in your hand. It can also increase the strength of the print by reducing stress concentration points caused by layer lines.

Furthermore, a smoother surface reduces aerodynamic drag, making it ideal for drone parts, RC cars, and other aerodynamics applications.

PLA Smoothing Techniques

1. Sanding

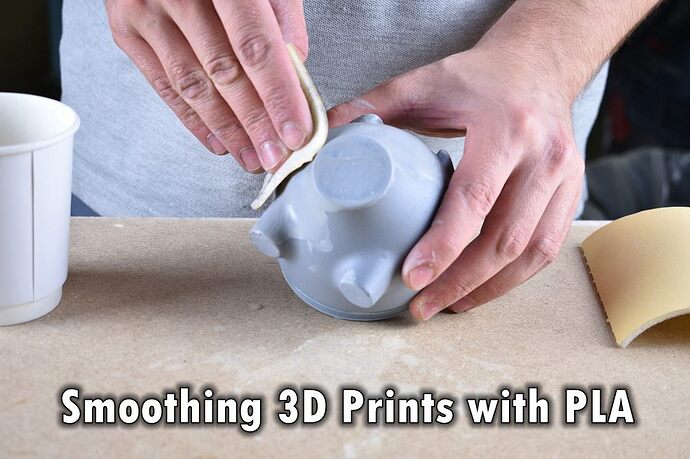

Sanding is one of the simplest and most common ways to smooth PLA prints. Start with a coarse-grit sandpaper (around 200 grit) to remove the larger imperfections and layer lines.

Then, gradually move to a finer grit (up to 2000 grit) for a polished finish. Remember to sand in a circular motion and keep the surface wet to prevent PLA from overheating and warping.

2. Chemical Smoothing

Chemical smoothing involves applying a solvent that can dissolve the PLA surface, resulting in a smooth finish. Ethyl Acetate is one such solvent that works well with PLA.

However, chemical smoothing requires careful handling of the solvent to avoid health and safety issues. Also, the process could potentially alter the dimensional accuracy of the print if not controlled properly.

3. Epoxy Coating

Applying an epoxy coating can give your PLA prints a smooth, glossy finish. Two-part epoxy resins are ideal for this. Mix the resin and hardener according to the manufacturer’s instructions and apply it evenly over the print.

Once the epoxy has cured, you can sand it to achieve a polished finish.

4. Heat Treatment

Heat treatment, also known as annealing, can also smooth PLA prints. However, this method requires precise control over the temperature as PLA has a low melting point.

The idea is to heat the print enough to allow the plastic to flow and fill in the layer lines, but not so much that it warps or deforms.

Tips for Smoothing PLA Prints

- Always wear safety equipment, like gloves and goggles, especially when dealing with solvents or heat treatments.

- If you’re sanding, it’s advisable to do it in a well-ventilated area or wear a dust mask to avoid inhaling PLA particles.

- When using chemical smoothing, ensure good ventilation and avoid skin contact with the solvent.

- For epoxy coatings, make sure the mix is accurate to avoid a sticky or brittle finish.

- Always test these techniques on a small, unimportant print before applying them to your main project.

Conclusion

In conclusion, PLA smoothing is a great way to enhance the finish of your 3D prints. Whether you choose sanding, chemical smoothing, epoxy coating, or heat treatment, you can achieve impressive results with some practice and care.

Remember, the key to a successful PLA smoothing process lies in your patience and attention to detail. With time, you can transform your 3D prints from ordinary to extraordinary. Happy printing!