ISSUE: K1 Max fails bed leveling from Mainsail Web-UI Screen. Manual calibration from K1 Max touchscreen completes, but still rams print head into the side of the printer.

System:

K1 Max - rooted with 1.3.3.5 firmware installed. Mainsail interface used from web browser on Win10 PC. My K1 Max is a December 2023 build, no physical modifications have been made. Initial bed mesh calibration was error free. Use of K1 Max, to this point in time, has been error free.

Error messages:

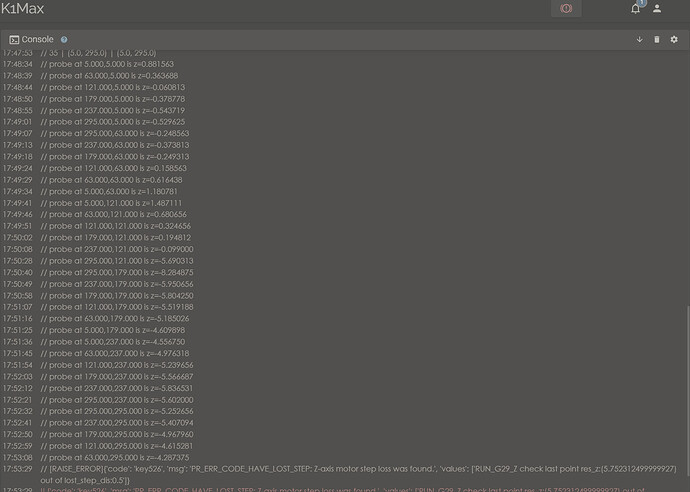

{‘code’: ‘key526’, ‘msg’: ‘PR_ERR_CODE_HAVE_LOST_STEP: Z-axis motor step loss was found.’, ‘values’: [‘RUN_G29_Z check last point res_z:(6.637994318181832) out of lost_step_dis:0.5’]}

[RAISE_ERROR]{‘code’: ‘key526’, ‘msg’: ‘PR_ERR_CODE_HAVE_LOST_STEP: Z-axis motor step loss was found.’, ‘values’: [‘RUN_G29_Z check last point res_z:(6.637994318181832) out of lost_step_dis:0.5’]}

How it happened:

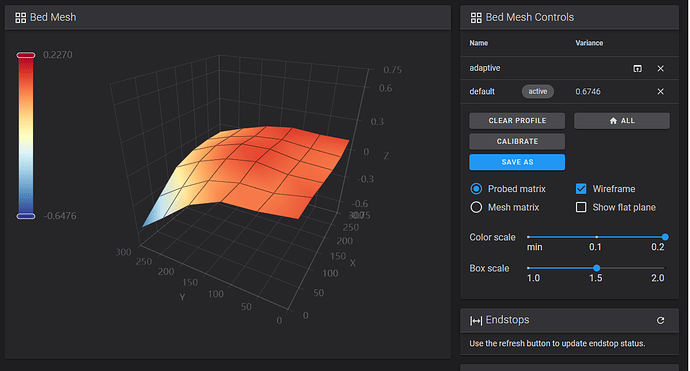

After months of light use, I decided to rerun the bed calibration because my PETG was starting to fail at the first layer after a few days of use. Today I used the bed mesh calibration from the Mainsail menu. In performing the last row of measurements at the very last point (left, rear), the print head slams into the corner. It does not do that for any other measurements of the left side. These two error messages appear in the dialog box and no new meshes have been created or saved. Subsequent bed mesh calibrations from the web UI fail in the same way. I do not have KAMP installed in the firmware.

I ran the bed mesh test from the touchscreen on the K1 Max. This time it completed without error but the print head still slammed into the rear left corner again. I had to type SAVE_CONFIG in the web UI to update the printer.cfg file with the latest bed mesh. Otherwise this mesh would have been lost when I turned off the printer.

I’ve read the blog post: https://store.creality.com/blog/creality-k1-max-fault-codes-list

But this list only details Key500 - Key508. It then skips to 2000. I hope someone from Creality sees this and can point me to the documentation which explain these error messages or can tell me what is happening. Thank you for reading.

^^^^^

This has been the bane of my existence for 2 weeks now!

I do a fair bit of tech-ing and trouble shooting, but can’t solve this! Rooted to find the issue and these are the exact errors I receive, numbers are slightly different.

I had KAMP, removed it, got it from a dif repository, on and on. I don’t think it’s the issue, I can post all my config files, but they look ok.

The problem is deeper. The nozzle is supposed to be an End Stop. Why is this failing?

Thanks. Interesting that it seems to describe the error, but it makes me wonder why it issues a 526 instead of 2526. It doesn’t do that for other errors in the 2xxx range. I wonder if it is a legacy error trap.

As @Zerquetch notices, too, the print head is supposed to act as a virtual endstop. I could run some more tests to see how far back the print head goes before ramming into the corner (or not, it shouldn’t). The answer may be buried in the source code, which I don’t have access to.

I have this same error right out of the box, it destroyed 2 bed plates by crashing into the nozzle. Please tell me you have found a fix!

Has there been any progress on this? I’ve actually been struggling with this for months. I installed KAMP a while ago, and it does the local probing well for smaller parts. However when it starts to include that back left corner, or if I use the Creality slicer with it’s full-bed default probing, I continually get the error.

I’m thought-experimenting my way through possible causes, and one that I can’t explain away would be a faulty strain gauge. I should find a replacement to test the theory.

I took the bed apart some time ago to check out a few things. I installed knobs to adjust the bed but my 1st set of springs were slightly too large…I went on anyway wondering if I could trip all 4. Nope. Errors out at the 1st one.

Put in new dif springs, issues abound, but eventually got it settled down to around 1.2mm variance.

From then on, I did a factory reset each time I tweaked the bed. That did wonders! Got to the point I could print again but the quality was lacking.

**I have over 200 pix of this that I won’t clog up the servers with.

Then the day came - No more warranty, now I can take the kid gloves off

A new fw update came along, and CPrint 5…well.

I disassembled to bed and took a hammer to it knowing full well where the humps and bumps are.

Got the bed to within 0.5mm at any given temperature. Blindly did a fairly large test print and it turned out OK. Not great, but passable.

Doing the factory resets works. Seems to clear whatever artifacts it has stored. I still have a few issues, unrelated, but the sensor issue has disappeared.

So the advice I have is: Clear your Bed Mesh data (if you can access it via browser, unrooted, ditch that one), reset. Test print fast 1st layer w calibration and see what the bed is at.

Tuning w springs and knobs works, but always give it about 5-10min at temp before printing.

Hope it helps!