Hi all,

just found a single post about the new Ender-3 V3s but that didn’t address the problems I face so I`ll try it here.

I`m pretty new to 3D printing and maybe you can help me out a bit if I miss some basics.

I have the issue that my printer does things at the beginning that doesn’t make 100% sense to me.

Question 1)

When I use the Creality Slicer and look at the start / end g-code it just has the following default text:

Start:

M140 S0

M104 S0

START_PRINT EXTRUDER_TEMP=[nozzle_temperature_initial_layer] BED_TEMP=[bed_temperature_initial_layer]

End:

END_PRINT

What I found so far:

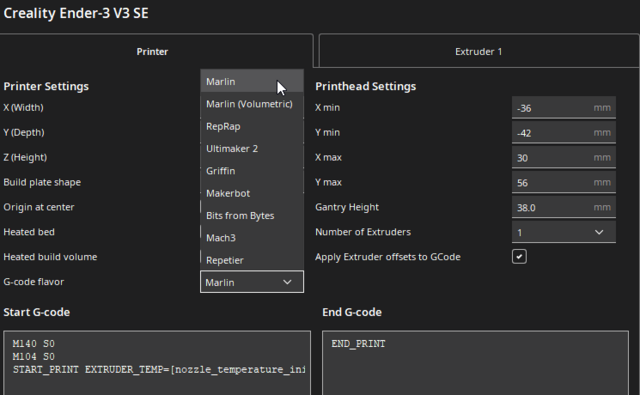

The new Enders have a Klipper-Based Creality OS.

I can’t select Klipper as a G-Code Flavor. Does this somehow create an issue?

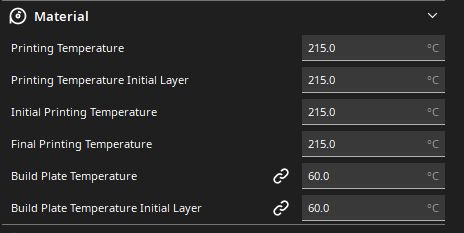

Because I set the printing temperature to 215°C at all points, but shortly before the nozzle purge at the edge of the bed starts, it’s rising up to 240°C and stays there.

I have no explenation why. I set the default material print temp to 215°C and also all other temps.

What am I missing that the extruder temp moves to 240°C all the time?

For comparison, the default Ender 3 V3-SE G-Code in Cura looks like that:

Start:

M220 S100 ;Reset Feedrate

M221 S100 ;Reset Flowrate

G28 ;Home

M420 S1; Use saved mesh leveling data

G92 E0 ;Reset Extruder

G1 Z2.0 F3000 ;Move Z Axis up

G1 X-3 Y20 Z0.28 F5000.0 ;Move to start position

M190 S{material_bed_temperature_layer_0} ; Set bed temperature and wait

M109 S{material_print_temperature_layer_0} ; Set hotend temperature and wait

G1 X-3 Y100.0 Z0.28 F1500.0 E15 ;Draw the first line

G1 X-2 Y100.0 Z0.28 F5000.0 ;Move to side a little

G1 X-2 Y20 Z0.28 F1500.0 E30 ;Draw the second line

G92 E0 ;Reset Extruder

G1 E-1.0000 F1800 ;Retract a bit

G1 Z2.0 F3000 ;Move Z Axis up

G1 E0.0000 F1800

End:

G91 ;Relative positioning

G1 E-2 F2700 ;Retract a bit

G1 E-2 Z0.2 F2400 ;Retract and raise Z

G1 X5 Y5 F3000 ;Wipe out

G1 Z10 ;Raise Z more

G90 ;Absolute positioning

G1 X0 Y{machine_depth} ;Present print

M106 S0 ;Turn-off fan

M104 S0 ;Turn-off hotend

M140 S0 ;Turn-off bed

M84 X Y E ;Disable all steppers but Z

When using this G-Code I`m running into a coordinate error on every print.

For now I put the short version in Klipper-Style into Cura and that starts the print at least.

Question 2)

When starting a print the printer levels the bed every time. Is that normal or somewhere hidden in “START_PRINT”?

Question 3)

Between leveling it cleans the nozzle. While doing this it’s scratching the bed a little. Is that hard pressure normal?

Thanks to every reply!