Hi there,

I’m new to this forum and to filament printing( have been resin printing for 6 years). Anyways, Just set up my new printer yesterday and did the speed test and abenchy using the supplied white PLA. The two items printed out perfectly.

Today I printed out the filament side mount detector and half of all of the parts for a lid riser,they turned out perfect. For the third print of the day, also one of the rise parts it turned out stringy and missing walls…. So what I found after canceling the print and starting more test prints is, that It lays down the first row and brim perfectly but when it starts doing walls and infill at fast speed it appears the filament flow is not keeping up.

If I push on the filament just outside of the detector while a print is going, the build quality improves. There’s is no tangling off of the spool, I’m watching it as it prints. So I figured it might be the extruder. Did a retract unlatched the extruder and tugged the filament out, it was hard to get out. Then I tried to reinstall the filament it wouldn’t go in so I took the extrudedr apart and cleaned out the chunk. Put it back together and tried a benchy and it failed, not enough filament coming out after the first layer.

Is it possible the hot end is clogged, maybe some contamination?

PLA was in a dryer, prior to printing.

Any suggestions of what to look for to get this unclogged?

Hello @AntaresSky …! ![]()

Welcome to the Creality Forum…! ![]()

What are your temps. (Nozzle and Build Plate)

We need to check one thing at a time here to see what’s causing it.

First to check is that when printing PLA it’s best to keep the top cover off.

If the chamber temp gets too warm PLA doesn’t like it.

It will soften and clog everything up…

If the filament is hard to pull out after you retract try another retraction otherwise it might break off inside and you’ll end up taking it apart…

Thanks for the welcome! ![]()

Looks like I have the problem figured out!!! ![]()

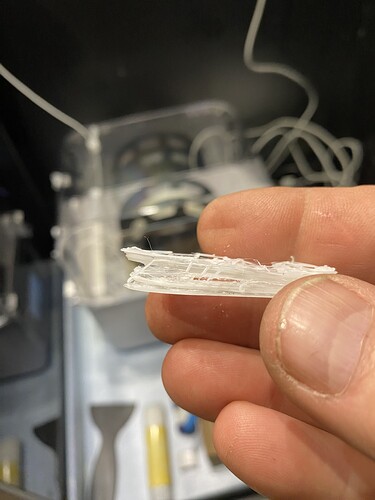

I took the nozzle out and used the cleaning rod to probe the nozzle.

There was melted PLA filament on the walls, using the tool I was able to scrap most of it off the walls and just tapped the top on a hard surface to clear the flakes out.

It now manually extrudes better, but not 100%. will replace the nozzle and give this one a better cleaning.

To answer you questions:

- used the supplied Hyper white PLA

- plate temp 45

- nozzle temp 220

- lid off the entire time

Il update as to why I think the PLA melted in the top of the nozzle in a while!

PS: I don’t recommend using the supplied cleaning rod through the extruder! As you retract the rod back up it pulls melted filament up into the extruder and it cools and jams.

Glen

So, here is what I think clogged the nozzle.

The lid riser project has 5 plates. plate number four, when I exported the slice and saved it to my laptop, said PETG in the file name. I thought that was weird, but being new to filament printing I just changed the file name to PLA and proceeded to print this slice. That when all heck broke loose, and the sh/t hit the proverbial fan! I’m guessing that sliced file despite me selecting PLA before slicing saved the Gcode for PETG and used a higher temp that is not PLA friendly. When I went back into Creality print to look at the settings, I also noticed the selected printer was K1 and not K1C as previously selected. I resliced the plate and this time it saved as PLA in the file name.

I’ll retry printing that file again once a new nozzle is installed.

I still have a bit of PLA stuck in the upper portion of the nozzle. My latest test Benchy is not perfect, but much better. It’s missing a little section of outside wall.

I’m going to try dissolving the PLA in the nozzle with some MEK!?!?!?!? not sure if that will work!

And give it an ultrasonic bath.

Glen

Installed a new nozzle and all is good!

Glen

Good to hear… ![]()

Thanks for sharing your experience which I’m sure will help someone else… ![]()